Filter by

For Use With

Housing Material

Maximum Flow Rate

Voltage

Diaphragm Material

Maximum Temperature

Priming Type

Maximum Pressure

Maximum Feet of Head

DFARS Specialty Metals

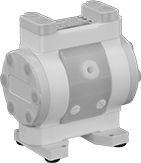

PTFE Air-Powered Double Diaphragm Pumps for Harsh Chemicals

Threaded Side Intake and Threaded Side Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | Max. Solids Dia. | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 0.06" | 4.8 | 1/8 Female NPT | 1/4 Female NPT | 1/4 Female NPT | 3 3/8" | 5 1/2" | 6 1/2" | 000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.7 | 0.08" | 9.3 | 1/8 Female NPT | 3/8 Female NPT | 3/8 Female NPT | 3 1/2" | 5 7/8" | 7 5/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.16" | 29 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 6" | 9 3/16" | 8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 39 | 0.24" | 46 | 1/4 Female NPT | 1 Female NPT | 1 Female NPT | 8" | 10 7/8" | 10 3/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed-Flow-Rate Peristaltic Pumps for Chemicals

Pumps | Replacement Pump Heads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gal./day (For Tube ID) | Max. Pressure, psi | Max. Viscosity, cP | Temp., ° F | Power | Current, amp | Lg. | Wd. | Ht. | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115V AC, Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF and Viton® Fluoroelastomer Wetted Parts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02 (1/32") 0.07 (1/16") 0.25 (1/8") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 0000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11 (1/32") 0.34 (1/16") 1.25 (1/8") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.87 (1/16") 3.53 (1/8") 6.84 (3/16") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.75 (1/16") 7.07 (1/8") 13.68 (3/16") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22.8 (3/16") 38 (1/4") | 15 | 500 | 32 to 122 | Fractional | 0.52 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45.6 (3/16") 76 (1/4") | 15 | 200 | 32 to 122 | Fractional | 0.65 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 228 (3/16") 380 (1/4") | 15 | 50 | 32 to 122 | Fractional | 1.74 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Foot-Operated Drum Pumps for Harsh Chemicals

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Spout Type | Drum Pump Type | Each | |||

| 5 | 30 | 500 | 35 | 100 | 1 1/8" to 2 3/4" | Drum Connector | 5/8" | 13" to 28" | Spout End | Removable | Pedal | 0000000 | 0000000 | ||

Drum Pumps for Harsh Chemicals

Pump Pulsation Dampers for Air-Powered Transfer Pumps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake Pipe Connections (NPT) | Air Connection (NPT) | Housing Material | Dia. | Ht. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Bottom Intake | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ½ Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | 1 NPT to 1/2 NPT Adapter | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ¾ Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | 1 NPT to 3/4 NPT Adapter | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 ½ Female | ⅛ Female | 316L Stainless Steel | 13 3/4" | 8 3/16" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Female | ⅛ Female | 316L Stainless Steel | 13 3/4" | 8 3/16" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||