How to Prime Your Pump

More

How to Determine Feet of Head

More

About Sump, Water-Removal, Condensate, and Submersible Pumps

More

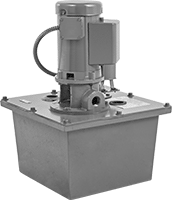

Steam Condensate Pumps with Tank

Designed for use in low-pressure steam systems, these pumps capture steam in the attached tank and return hot condensate to your boiler or feed unit. They are activated by a float switch, turning on and off when condensate level reaches a certain depth.

Pumps with cast iron tank are for continuous use and have a longer service life than carbon steel.

Maintenance kit for pump with cast iron tank includes a shaft, a bushing, a thrust washer, a spring washer, an oil seal, and snap rings.

Max. Flow Rate, gpm | Level | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Connection Type | Tank Cap., gal. | @ 35 Ft. of Head | @ 50 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn On | Turn Off | Temp. Range, °F | Horsepower | Current, A | Intake Pipe Size | Discharge Pipe Size | Ht. | Wd. | Dp. | Each | |

120V AC/240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

| Hardwire | 8 | 6.5 | 5.8 | 69 | 30 | 7 1/4" | 5 1/4" | 160° to 200° | 1/4 hp | 2.5/5 | 2 NPT Female | 1 NPT Female | 26" | 17" | 17" | 0000000 | 000000000 |

| Hardwire | 8 | 13 | __ | 46 | 20 | 7 1/4" | 5 1/4" | 160° to 200° | 1/3 hp | 3.2/6 | 2 NPT Female | 1 NPT Female | 26" | 17" | 17" | 0000000 | 00000000 |

| Maintenance Kit | 0000000 | Each | 0000000 |

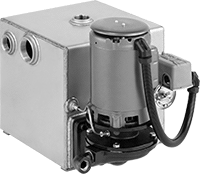

Corrosion-Resistant Steam Condensate Pump with Tank

The stainless steel tank has excellent corrosion resistance. Designed for use in low-pressure steam systems, these pumps capture steam in the attached tank and return hot condensate to your boiler or feed unit. They are activated by a float switch, turning on and off when condensate level reaches a certain depth.

Max. Flow Rate, gpm | Level | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tank Cap., gal. | @ 1 Ft. of Head | @ 10 Ft. of Head | @ 35 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn On | Turn Off | Temp. Range, °F | Horsepower | Current, A | Intake Pipe Size | Discharge Pipe Size | Ht. | Wd. | Dp. | Each | |

120V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

Hardwire | |||||||||||||||||

| 8 | 44 | 41 | 26 | 46 | 20 | 7" | 4 1/2" | 35° to 250° | 1/3 hp | 5.6 | 2 NPT Female | 3/4 NPT Female | 12 1/2" | 12 1/2" | 21 1/2" | 00000000 | 000000000 |

| 15 | 44 | 41 | 26 | 46 | 20 | 9" | 4 1/2" | 35° to 250° | 1/3 hp | 5.6 | 2 NPT Female | 3/4 NPT Female | 14 3/8" | 17" | 23 1/4" | 00000000 | 00000000 |

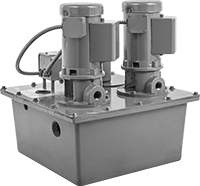

Extended-Life Steam Condensate Pumps with Tank

To handle high condensate volume, the workload is distributed between two pumps for a longer service life than standard steam condensate pumps. The second pump provides redundancy so one pump can operate while you work on the other. Use in low-pressure steam systems to capture hot condensate and return it to your boiler or feed unit. Pumps turn on and off when condensate level reaches a certain depth.

Maintenance kit includes a shaft, a bushing, a thrust washer, a spring washer, an oil seal, and snap rings. Purchase two kits to repair this pump.

Max. Flow Rate, gpm | Level | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tank Cap., gal. | @ 35 Ft. of Head | @ 50 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn On | Turn Off | Temp. Range, °F | Horsepower | Current, A | Intake Pipe Size | Discharge Pipe Size | Ht. | Wd. | Dp. | Each | |

120V AC/240V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||

Hardwire | ||||||||||||||||

| 15 | 13 | 12 | 46 | 20 | 6 1/2", 7 1/2" | 4 1/4", 5 1/4" | 160° to 200° | 1/3 hp | 3.2/6 | 2 NPT Female | 1 NPT Female | 24" | 22 1/2" | 22 1/2" | 0000000 | 000000000 |

| Maintenance Kit | 0000000 | Each | 0000000 |

High-Flow Steam Condensate Pumps with Tank

Move a higher volume of condensate than standard steam condensate pumps. Use these pumps in low-pressure steam systems to capture hot condensate and return it to your boiler or feed unit. They turn on when the tank is 2/3 full and turn off when condensate drops to 6" deep.

Max. Flow Rate, gpm | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tank Cap., gal. | @ 35 Ft. of Head | @ 50 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn-Off Level | Temp. Range, °F | Horsepower | Current, A | Intake Pipe Size | Discharge Pipe Size | Ht. | Wd. | Dp. | Each | |

120V AC/240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||

Hardwire | |||||||||||||||

| 6 | 35 | 25 | 71 | 25 | 6" | 30° to 210° | 1/3 hp | 4.4/8.8 | 2 NPT Female | 1 NPT Female | 13" | 15" | 26" | 0000000 | 000000000 |

| 15 | 35 | 25 | 71 | 25 | 6" | 30° to 210° | 1/3 hp | 4.4/8.8 | 2 NPT Female | 1 NPT Female | 20" | 18" | 27" | 0000000 | 00000000 |

| 20 | 35 | 25 | 71 | 25 | 6" | 30° to 210° | 1/3 hp | 4.4/8.8 | 2 NPT Female | 1 NPT Female | 19" | 25" | 25" | 0000000 | 00000000 |

| Maintenance Seal Kit | 0000000 | Each | 0000000 |

| Replacement Float Switch for Pumps with 15 gal. and 20 gal. Tank Cap. | 0000000 | Each | 000000 |

| Replacement Impeller | 0000000 | Each | 000000 |

| Replacement Tank Gasket | 0000000 | Each | 00000 |

| Replacement Pump and Motor Assembly Kit | 0000000 | Each | 00000000 |

| Replacement Vent Pipe Assembly | 0000000 | Each | 00000 |

| Replacement Float Switch for Pumps with 6 gal. Tank Cap. | 0000000 | Each | 000000 |

Extended-Life High-Flow Steam Condensate Pumps with Tank

To handle high condensate volume, the workload is distributed between two pumps for a longer service life than standard high-flow steam condensate pumps. The second pump provides redundancy so one pump can operate while you work on the other. These pumps move a higher volume of condensate than standard steam condensate pumps. Use them in low-pressure steam systems to capture hot condensate and return it to your boiler or feed unit. Pumps turn on when the tank is 2/3 full and turn off when condensate drops to 6" deep.

Max. Flow Rate, gpm | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tank Cap., gal. | @ 35 Ft. of Head | @ 50 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn-Off Level | Temp. Range, °F | Horsepower | Current, A | Intake Pipe Size | Discharge Pipe Size | Ht. | Wd. | Dp. | Each | |

120V AC/240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||

Hardwire | |||||||||||||||

| 15 | 35 | 25 | 71 | 25 | 6" | 35° to 210° | 1/3 hp | 4.4/8.8 | 2 NPT Female | 1 NPT Female | 20" | 18" | 27" | 0000000 | 000000000 |

| 20 | 35 | 25 | 71 | 25 | 6" | 35° to 210° | 1/3 hp | 4.4/8.8 | 2 NPT Female | 1 NPT Female | 21" | 25" | 25" | 0000000 | 00000000 |

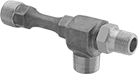

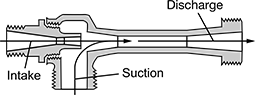

Steam-Powered Jet Pumps

Use plant steam to pump liquids and gases, prime pumps, and remove fumes. When high-pressure steam enters the intake, it creates suction that draws a second liquid or gas into the pump body and discharges a pressurized blend of the two. The discharge pressure is greater than the suction flow but lower than the intake pressure. Gas suction flow is calculated using steam at atmospheric pressure. They have no moving parts or seals, eliminating downtime for lubrication and repairs. They're also known as eductors, ejectors, and injectors.

Note: Liquid suction flow rate is calculated using 80 psi steam at 0-40 feet of discharge head.

Bronze is more corrosion resistant than steel.

316 stainless steel pumps provide the most corrosion resistance.

Liquid Suction Flow Rate, gpm | Gas Suction Flow, cfm | Intake Pressure, psi | Suction | Intake | Discharge | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 ft. of Lift | 10 ft. of Lift | @ 20 ft. of Lift | @ 20 psi Steam | @ 50 psi Steam | @ 80 psi Steam | Max. Suction Lift, ft. | For Liquids | For Gases | Temp. Range, °F | Pipe Size | Thread Type | Pipe Size | Thread Type | Pipe Size | Thread Type | Lg. | Wd. | Each | |

For Use With Air, Inert Gas, Steam, Water | |||||||||||||||||||

Steel | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 0000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

Bronze | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -20° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -20° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -20° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 31 | 27 | 15 | 24 | 20 | 17 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/4 | NPT | 1 | NPT | 1 1/4 | NPT | 9" | 2 3/8" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -20° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -20° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 000000 |

316 Stainless Steel | |||||||||||||||||||

| 6 | 5 | 3 | 5 | 4 | 3 | 20 | 35-150 | 20-80 | -150° to 150° | 1/2 | NPT | 3/8 | NPT | 1/2 | NPT | 4 1/2" | 1 1/8" | 0000000 | 000000 |

| 10 | 9 | 5 | 8 | 6 | 6 | 20 | 35-150 | 20-80 | -150° to 150° | 3/4 | NPT | 1/2 | NPT | 3/4 | NPT | 5 7/8" | 1 1/4" | 0000000 | 000000 |

| 17 | 15 | 9 | 14 | 11 | 10 | 20 | 35-150 | 20-80 | -150° to 150° | 1 | NPT | 3/4 | NPT | 1 | NPT | 7 1/8" | 1 3/4" | 0000000 | 000000 |

| 51 | 44 | 25 | 40 | 32 | 28 | 20 | 35-150 | 20-80 | -150° to 150° | 1 1/2 | NPT | 1 | NPT | 1 1/2 | NPT | 11" | 2 5/8" | 0000000 | 00000000 |

| 93 | 80 | 46 | 73 | 58 | 51 | 20 | 35-150 | 20-80 | -150° to 150° | 2 | NPT | 1 1/4 | NPT | 2 | NPT | 14 3/8" | 3 1/2" | 0000000 | 00000000 |

Mechanical Pump Shaft Seals with Extended Spring

For use in waste water, boiler feed, and compressor pumps, these seals have an extra-long spring that accommodates variations in seal cavity length. They come furnished as two pieces—the seal and the seat. The seal is comprised of the case, spring, diaphragm, and washer, which come locked together as one piece. Seal Width represents the working height, which is the compressed length when installed. The seat is comprised of the seat and the gasket. Products cannot be sold outside North America due to restrictions.

EPDM diaphragms are more resistant to water and steam than Buna-N and Viton® fluoroelastomer, but aren’t as resistant to oils and chemicals.

Carbon washers are for use with clean liquids.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

Seal | Seat | Material | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Manufacturer Equivalent Number | Manufacturer/ Brand Equivalent | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Spring Shape | Includes | Max. Pressure, psi | Cannot Be Sold To | Each | |

304 Stainless Steel Case and Spring with EPDM Rubber Diaphragm and Gasket | ||||||||||||||||

| 1/2" | 168E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 0.500" | 0.915" | 0.812" | 0.535" | 1.000" | 0.312" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

| 5/8" | 359E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 0.625" | 1.180" | 0.875" | 0.671" | 1.250" | 0.406" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 3/4" | 358E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 0.750" | 1.302" | 0.875" | 0.780" | 1.375" | 0.406" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 0000000 | 00000 |

| 7/8" | 703E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 0.875" | 1.422" | 0.937" | 0.921" | 1.500" | 0.406" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1" | 235E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.000" | 1.552" | 1.000" | 1.031" | 1.625" | 0.437" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 1/8" | 356E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.125" | 1.753" | 1.062" | 1.161" | 1.750" | 0.439" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 1/4" | 185E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.250" | 1.878" | 1.062" | 1.291" | 1.875" | 0.437" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 3/8" | 177E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.375" | 2.001" | 1.125" | 1.411" | 2.000" | 0.437" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 1/2" | 758E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.500" | 2.124" | 1.125" | 1.546" | 2.125" | 0.437" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 5/8" | 238E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.625" | 2.446" | 1.375" | 1.663" | 2.375" | 0.500" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 3/4" | 237E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.750" | 2.446" | 1.312" | 1.796" | 2.500" | 0.500" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 1 7/8" | 340E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.875" | 2.519" | 1.500" | 1.927" | 2.625" | 0.500" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

| 2" | 267E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 2.000" | 2.724" | 1.500" | 2.055" | 2.750" | 0.500" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

Seal | Seat | Material | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Manufacturer/ Brand Equivalent | ID, mm | OD, mm | Wd., mm | ID, mm | OD, mm | Wd., mm | Washer | Seat | Spring Shape | Includes | Max. Pressure, psi | Cannot Be Sold To | Each | |

304 Stainless Steel Case and Spring with EPDM Rubber Diaphragm and Gasket | |||||||||||||||

| 12 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 12.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

| 16 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 16.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

| 25 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 25.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |