Filter by

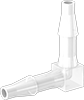

Fitting Connection

Tube ID

Connects To

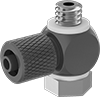

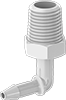

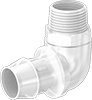

Fitting Type

For Use With

DFARS Specialty Metals

Conduit Type

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More