Filter by

Fitting Connection

Environment

Maximum Pressure @ Temperature

RoHS

DFARS Specialty Metals

Tube Material

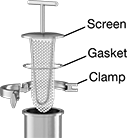

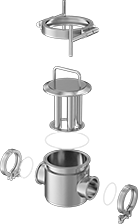

Stainless Steel Quick-Clamp T-Strainers

Strainers | Replacement Clamps | Replacement Screens | Replacement Gaskets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flange OD | Max. Pressure @ Temp. | Temp. Range, ° F | Lg. | Ht. | Screen Material | Screen Opening Size | Screen Lg. | Each | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Use With Beverage, Dairy, Food, Pharmaceuticals, and Water | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.984" | 150 psi @ 72° F | -50 to 275 | 5 1/2" | 5 7/8" | 316 Stainless Steel | 1/8" | 3 1/2" | 0000000 | 0000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.516" | 150 psi @ 72° F | -50 to 275 | 7" | 6 7/8" | 316 Stainless Steel | 1/8" | 4 1/2" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3.047" | 150 psi @ 72° F | -50 to 275 | 7" | 7 3/16" | 316 Stainless Steel | 1/8" | 4 3/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.579" | 150 psi @ 72° F | -50 to 275 | 7 1/2" | 7 11/16" | 316 Stainless Steel | 1/8" | 5 1/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

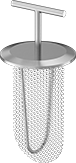

Sanitary Magnetic Strainers

Pipe Size | Max. Magnetic Pull, lbf | Max. Pressure @ Temp. | Temp. Range, ° F | Lg. | Ht. | Magnet Material | Gasket Material | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Use With Beverage, Dairy, Food, Salt Solutions, Sodium Nitrate, and Water—FDA Compliant 21 CFR 177.2600 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 14.25 | 150 psi @ 225° F | -20 to 225 | 9 3/4" | 9 3/8" | Neodymium | Buna-N | — | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 14.25 | 150 psi @ 225° F | -20 to 225 | 9 3/4" | 11 7/8" | Neodymium | Buna-N | USDA Accepted Equipment | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14.25 | 150 psi @ 225° F | -20 to 225 | 9 13/16" | 9 3/8" | Neodymium | Buna-N | — | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14.25 | 150 psi @ 225° F | -20 to 225 | 9 13/16" | 11 7/8" | Neodymium | Buna-N | USDA Accepted Equipment | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Quick-Clamp T-Strainer Screens

For Tube OD | For Flange OD | Screen Lg. | Screen Material | Screen Opening Size | For Use With | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Perforated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.984" | 3 1/2" | 316 Stainless Steel | 1/8" | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.516" | 4 1/2" | 316 Stainless Steel | 1/8" | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3.047" | 4 3/4" | 316 Stainless Steel | 1/8" | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.579" | 5 1/4" | 316 Stainless Steel | 1/8" | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sediment Traps

Cap., gal. | Inlet Pipe Size | Inlet Ht. | Outlet Pipe Size | Outlet Ht. | Ht. | Wd. | Dp. | Gasket Material | Max. Temp., ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Threaded NPT Male Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1 1/2 | 9" | 1 1/2 | 9" | 12 1/2" | 13" | 13" | Buna-N | 230 | Removable Basket, Clamps with Thumbscrews | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||