How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

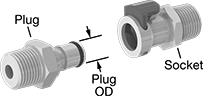

Quick-Disconnect Tube Couplings for Food and Beverage

- Temperature Range:

Acetal Plastic: -40° to 180° F

Polypropylene Plastic: 32° to 160° F - Tubing:

Barbed Fittings: Use with soft or firm (Durometer 65A-80A) polyurethane rubber

Compression Fittings: Use with hard or firm (Durometer 80A-60D) nylon or polyethylene plastic - Specifications Met: NSF/ANSI 169

Couplings consist of a plug and a socket (sold separately) that join with a latch, so you can frequently connect and disconnect your line. To connect, insert the plug into the socket; to disconnect, press the latch on the socket and remove the plug. They’re made of FDA-approved materials, including moisture-resistant plastic that won’t absorb liquid and lose strength, even in high-humidity food and beverage applications.

Plugs and sockets with shut-off have a valve to stop the flow when the coupling is separated, so fluid won’t spill from your line.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

Barbed plugs insert into tubing and secure with a clamp.

| Coupling Size | Plug OD | For Tube ID | Material | Color | Clarity | Max. Pressure | Each | |

Open Flow | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 7/16" | 1/4" | Acetal Plastic | White | Semi-Clear | 100 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 7/16" | 3/8" | Acetal Plastic | White | Semi-Clear | 100 psi @ 72° F | 0000000 | 0000 |

With Shut-Off | ||||||||

| 1/4 | 7/16" | 1/4" | Acetal Plastic | White | Semi-Clear | 100 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 7/16" | 3/8" | Acetal Plastic | White | Semi-Clear | 100 psi @ 72° F | 0000000 | 00000 |

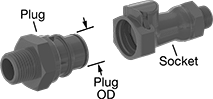

Quick-Disconnect Tube Couplings for Chemicals

Couplings consist of a plug and a socket (sold separately) that join with a latch, so you can frequently connect and disconnect your line. To connect, insert the plug into the socket; to disconnect, press the latch on the socket and remove the plug. Plugs and sockets are polypropylene, which has excellent chemical, impact, and abrasion resistance.

Plugs and sockets with shut-off have a valve to stop the flow when the coupling is separated so fluid won’t spill from your line.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

- For Use With: Ammonia, Ethanol, Phosphoric Acid (70%), Sodium Carbonate

- Temperature Range: 32° to 160° F

Barbed plugs insert into tubing and secure with a clamp.

Open Flow | With Shut-Off | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Coupling Size | Plug OD | Material | Color | Max. Pressure | Each | Each | ||

| 1/8" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| 1/4" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/4" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/2" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

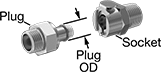

High-Pressure Quick-Disconnect Tube Couplings for Air

Not only are these chrome-plated brass couplings corrosion resistant, they’re also durable enough to handle pressures up to 250 psi and can be used with vacuum. Couplings consist of a plug and a socket (sold separately) that join with a latch, so you can frequently connect and disconnect your line. To connect, insert the plug into the socket; to disconnect, press the latch on the socket and remove the plug.

Plugs and sockets with open flow control give you higher flow rates than those with shut-off flow control. They also minimize pressure drops across the connection. For the best flow rates, pair an open flow plug with an open flow socket. Plugs and sockets with shut-off flow control have a valve that stops air from leaking out when you detach the coupling.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

- Temperature Range: -40° to 180° F

- Tubing: Use with soft or firm (Durometer 70A-80A) polyurethane rubber

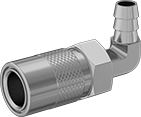

Barbed couplings tightly grip your tube or hose for a secure hold.

Open Flow | With Shut-Off | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube ID | Coupling Size | Plug OD | Material | Max. Pressure | Each | Each | ||

| 1/8" | 1/8 | 5/16" | Chrome-Plated Brass | 250 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| 1/4" | 1/8 | 5/16" | Chrome-Plated Brass | 250 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/4" | 1/4 | 7/16" | Chrome-Plated Brass | 250 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8" | 1/4 | 7/16" | Chrome-Plated Brass | 250 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

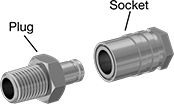

Quick-Disconnect Hose Couplings for Coolant

Also known as coolant-line mold couplings, these couplings are often used to install and remove coolant lines in molding and die casting applications. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them when you need frequent access to a line. All of the quick-disconnect coolant plugs are compatible with any of the quick-disconnect coolant sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Open-flow plugs and sockets do not have a shut-off valve, so the couplings allow for maximum flow. Sockets are sleeve-lock style. To connect, slide back the sleeve on the socket, insert the plug, and release the sleeve. To disconnect, slide back the sleeve and pull out the plug.

Sockets with a barbed end insert into plastic or rubber hose and secure with a clamp.

Brass plugs and sockets have better corrosion resistance than zinc-plated steel, and are softer, so they’re easier to thread together.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: For open-flow plugs and sockets, stop the flow of coolant before you disconnect the line.

- Maximum Pressure: 200 psi @ 72° F

- Temperature Range: -30° to 400° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Compatible With: Hansen FT

- Maximum Pressure: 200 psi @ 72° F

- Temperature Range: -30° to 400° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Compatible With: Foster FP, Foster FS, Hansen FT, Parker Moldmate

Metal Cam-and-Groove Hose Couplings for Water

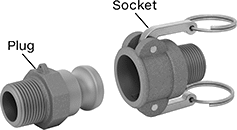

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance thanks to their anodized finish. Brass couplings are softer than aluminum plugs and sockets, so they’re easier to thread together. They have good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Attachment Type: Use Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

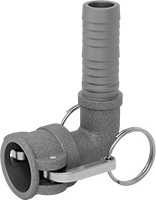

90° elbow sockets with barbed end are also known as CL couplers. Insert the barbed end into plastic or rubber hose and secure with a clamp.

Sockets | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Replacement Levers | |||||||||||

| Coupling Size | Socket ID | For Hose ID | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Anodized Aluminum | |||||||||||||

| 1 | 1 7/16" | 1" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 2 | 2 1/2" | 2" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 3 | 3 5/8" | 3" | 2 | 304 Stainless Steel | Stainless Steel | 200 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 4" | 2 | 304 Stainless Steel | Stainless Steel | 150 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

Brass | |||||||||||||

| 1 | 1 7/16" | 1" | 2 | Brass | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2" | 2 | Brass | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 2 | 2 1/2" | 2" | 2 | Brass | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 0000 | 000000 | 00 |

Plastic Cam-and-Groove Hose Couplings for Water

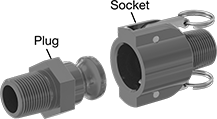

Made of polypropylene, these couplings are lighter in weight than metal cam-and-groove couplings and have good abrasion and corrosion resistance. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

90° elbow sockets with barbed end are also known as CL couplers. Insert the barbed end into plastic or rubber hose and secure with a clamp.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: 225 psi @ 72° F

- Temperature Range: -20° to 150° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Sockets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Protective Plugs | ||||||||||

| Coupling Size | Socket ID | For Hose ID | No. of | Material | Pull Ring Material | Each | Pkg. Qty. | Pkg. | Each | |||

Polypropylene Plastic | ||||||||||||

| 1 1/2 | 2 1/8" | 1 1/2" | 2 | 304 Stainless Steel | 304 Stainless Steel | 0000000 | 000000 | 10 | 0000000 | 000000 | 000000 | 00 |

| 2 | 2 1/2" | 2" | 2 | 304 Stainless Steel | 304 Stainless Steel | 0000000 | 00000 | 10 | 0000000 | 00000 | 00000000 | 000000 |