Filter by

Reamer Type

System of Measurement

Reamer Diameter

Flute Type

Number of Flutes

Material

DFARS Specialty Metals

RoHS

Export Control Classification Number (ECCN)

Sold As

Reach Length

Reamers for Morse Taper-Socket Holes

Square Shank

Reamers | Optional Straight-Handle Tap Wrenches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

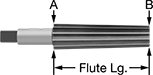

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Machine Taper No. | Reamer Dia. (A) | Reamer Dia. (B) | Material | Square Shank Size | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance | For Use On | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 0 | 0.3670" | 0.2500" | High-Speed Steel | 0.2350" | 2 1/4" | 3 3/4" | 6 | -0.0005" to 0.0005" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 1 | 0.5170" | 0.3670" | High-Speed Steel | 0.3300" | 3" | 5" | 6 | -0.0005" to 0.0005" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reamers

Round Shank

Straight Flute |

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3670" | High-Speed Steel | 1 3/4" | 7" | 6 | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3670" | Carbide | 1 3/16" | 4" | 6 | 0" to 0.0002" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||