How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

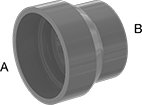

High-Purity PVDF Pipe Fittings for Corrosive Chemicals

Made of PVDF that’s finished to a 12 Ra smoothness, these fittings handle some of the harshest chemicals without leaching contaminants into your line. They won’t accumulate particles and are easy to clean, thanks to their smoothness. Comparable to Kynar, these fittings handle most organic solvents that would dissolve CPVC, and chlorine or nitric acid that would weaken polypropylene. You can use them at higher temperatures than CPVC and polypropylene. These fittings meet UL 94 V-0 and FM standards for flame retardance. They’re also FDA compliant for direct contact with food, and they meet ASTM requirements for dimensions and tolerances.

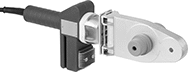

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3261, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Pipe Nipples and Pipe: Use SDR 21 PVDF Plastic

- Flanges: Use PVDF Plastic

(A) | (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Dp. | Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

| 3/4 | 35/64" | 1/2 | 35/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 | 5/8" | 1/2 | 5/8" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 | 5/8" | 3/4 | 5/8" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 45/64" | 1 | 45/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 2 | 45/64" | 1 | 45/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 2 | 29/32" | 1 1/2 | 29/32" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3222, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Seal Material: Viton® Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | White | 230 psi @ 72° F | 0000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| Each | ||

| 00000000 | 0000000 |

Gravity-Flow CPVC Pipe Fittings for Corrosive Chemical Waste

- For Use With: Hydrochloric Acid, Nitric Acid, Salt Water, Sulfuric Acid

- Temperature Range: 40° to 200° F

- Specifications Met: ASTM F2618, IAPMO Listed, NSF/ANSI 14, UL 94 V-0

Made of CPVC, these fittings have better chemical resistance than ABS plastic gravity-flow fittings and can stand up to highly-corrosive acids and other harsh substances. They meet NSF/ANSI 14 requirements for use in corrosive waste gravity-flow systems. Fittings are comparable to Corzan. They meet UL 94 V-0 for flame retardance and ASTM F2618 specifications and testing requirements for material quality. They are IAPMO certified to comply with the International Association for Plumbing and Mechanical Officials product performance standards and the Uniform Plumbing Code (UPC) for installation and repair of plumbing systems.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

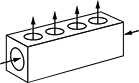

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

PTFE manifolds have the best chemical and corrosion resistance of all the plastic and metal manifolds we offer, so they’re the best choice for acids and other highly corrosive substances. Do not use with deonized water at temperatures above 120° F.

Use a plug (sold separately) to close off any unused inlets and outlets.

- For Use With: Acetic Acid, Acetone, Bleach, Deionized Water, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Temperature Range: -20° to 180° F

- Maximum Pressure: 120 psi @ 72° F

| No. of Outlets | Inlet Pipe Size | Outlet Pipe Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 1/4 | 1/8 | 1 3/4" | 1" | 1" | 3/4" | White | 0000000 | 000000 |

| 2 | 3/8 | 1/4 | 2 3/8" | 1 1/4" | 1 1/4" | 7/8" | White | 0000000 | 00000 |

| 2 | 1/2 | 3/8 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | White | 0000000 | 00000 |

| 4 | 1/4 | 1/8 | 3 1/4" | 1" | 1" | 3/4" | White | 0000000 | 00000 |

| 4 | 3/8 | 1/4 | 4 1/8" | 1 1/4" | 1 1/4" | 7/8" | White | 0000000 | 00000 |

| 4 | 1/2 | 3/8 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | White | 0000000 | 000000 |

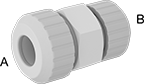

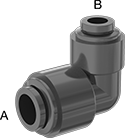

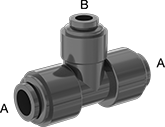

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

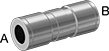

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

| 3/8" | 1/4" | PVDF Plastic | Black | Black | 300 psi @ 72° F | 1" | 5/8" | 00000000 | 000000 |

| For Tube OD (Push to Connect) | For Tube OD (Flared) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3/8" | 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 00000000 | 000000 |

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3/8" | 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 0000000 | 00000 |

Inline tees are also known as branch tees.

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3/8" | 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 0000000 | 000000 |

Stainless Steel Push-to-Connect Tube Fittings for Chemicals

- For Use With: Alcohol, Bleach, Lubricated Air, Nitric Acid, Sodium Carbonate, Sulfuric Acid

- Temperature Range: 0° to 175° F

- Tubing: Use with firm or hard (Durometer 80A-60D) FEP, polyethylene, or PTFE plastic

Fittings are 316 stainless steel, which has excellent chemical resistance and is more durable than plastic. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. Instead of a release ring, these fittings have a release sleeve that slides back to disconnect tubing.

| For Tube OD (A) | For Tube OD (B) | Material | Max. Pressure | Each | |

| 3/8" | 1/4" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 1/2" | 1/4" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 1/2" | 3/8" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 8mm | 6mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 00000 |

| 10mm | 6mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 10mm | 8mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 00000 |

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

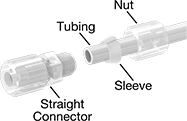

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PTFE fittings are highly resistant to most acids, alcohols, detergents, and solvents. They’re made by machining. Their nut is made of PVDF, which is resistant to halogens such as chlorine and bromine, strong acids such as hydrofluoric and nitric acids, and organic solvents.