Filter by

Handle Type

Handle Length

Hole Shape

Diameter

Grip Motion

Projection

DFARS Specialty Metals

Export Control Classification Number (ECCN)

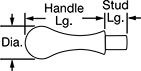

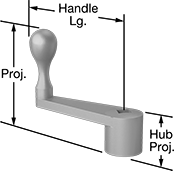

Tapered Lever Handles

|  |  |  |

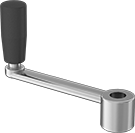

Style 1 (Revolving/Folding) | Style 1 (Revolving, Phenolic) | Style 1 (Revolving, Aluminum) | Style 3 (Revolving/Folding) |

Style 1—Threaded Stud with Smooth Revolving Handle

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 9/16" | 0.688" | 9/16" | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 2" | 0.813" | 11/16" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 9/16" | 2 9/16" | 0.938" | 3/4" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 3 1/8" | 1" | 13/16" | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 3 9/16" | 1 1/8" | 13/16" | Steel | -30 | 325 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 13/16" | 4" | 1 1/4" | 1" | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 40 mm | 18 mm | 15 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 50 mm | 21 mm | 17 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 15 mm | 65 mm | 23 mm | 19 mm | Steel | -30 | 325 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 80 mm | 26 mm | 21 mm | Steel | -30 | 325 | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 17 mm | 90 mm | 28 mm | 22 mm | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 20 mm | 102 mm | 31 mm | 25 mm | Steel | -30 | 325 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1 1/8" | 0.438" | 3/8" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 7/16" | 1 9/16" | 5/8" | 1/2" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 2" | 7/8" | 9/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2 1/2" | 1" | 3/4" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1/2" | 2 7/8" | 1 1/8" | 15/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1/2" | 3 1/4" | 1 1/4" | 15/16" | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 9 mm | 28 mm | 11 mm | 9 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 11 mm | 39 mm | 16 mm | 13 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 50 mm | 22 mm | 14 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 13 mm | 63 mm | 25 mm | 19 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 13 mm | 72 mm | 28 mm | 23 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 13 mm | 82 mm | 31 mm | 23 mm | Steel | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

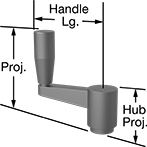

Style 1—Threaded Stud with Smooth Revolving/Folding Handle

Dia. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | (A) | (B) | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 3 3/8" | 0.91" | 3/4" | Steel | -50 | 200 | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 9/16" | 4" | 1.02" | 0.83" | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 13/16" | 4 1/2" | 1.1" | 0.91" | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 86 mm | 23 mm | 19 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 14 mm | 102 mm | 26 mm | 21 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 20 mm | 114 mm | 28 mm | 23 mm | Steel | -50 | 200 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3—Threaded Hole with Smooth Revolving/Folding Handle

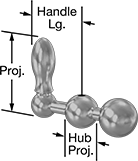

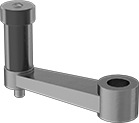

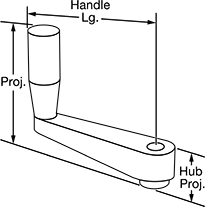

Unthreaded Through-Hole-Mount Crank Handles

|  |  |  |

Round Hole Style 1 | Round Hole Style 2 | Round Hole Style 4 | Round Hole Style 5 |

|  |  |  |

Round Hole Style 6 | Round Hole Style 7 | Round Hole Style 8 | Square Hole Style 10 |

Round Hole

|  |  |  |

Style 1 | Style 2 | Style 4 | Style 5 |

|  |  |  |

Style 6 | Style 7 | Style 8 |

Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Handle Lg. | Projection | Hub Projection | Hole Dia. | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Offset Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 80 mm | 112 mm | 24 mm | 8 mm | 74 mm | Zinc-Plated Steel | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 125 mm | 141 mm | 34 mm | 10 mm | 86 mm | Zinc-Plated Steel | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 160 mm | 162 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 315 mm | 248 mm | 54 mm | 20 mm | 143 mm | Zinc-Plated Steel | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 100 mm | 101 mm | 28 mm | 10 mm | 80 mm | Zinc-Plated Steel | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 mm | 116 mm | 34 mm | 10 mm | 90 mm | Zinc-Plated Steel | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 mm | 126 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 250 mm | 163 mm | 48 mm | 17 mm | 127 mm | Zinc-Plated Steel | — | — | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Painted Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 1/2" | 1 21/32" | 11/16" | 5/16" | 1 5/16" | Phenolic | Black | 0° F to 350° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 7/8" | 2 1/8" | 13/16" | 3/8" | 1 11/16" | Phenolic | Black | 0° F to 350° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 1/2" | 3" | 15/16" | 3/8" | 2 1/2" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 3/8" | 3 3/4" | 1 1/8" | 1/2" | 3 1/8" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 4 19/32" | 1 5/16" | 5/8" | 3 25/32" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 4 3/4" | 1 1/2" | 3/4" | 3 29/32" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 5/32" | 3 17/32" | 1 7/16" | 3/8" | 2 9/16" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 15/16" | 4 11/32" | 1 9/16" | 1/2" | 3 9/32" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 1/8" | 5 23/32" | 1 15/16" | 5/8" | 4 1/16" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 6 5/16" | 5 29/32" | 2 3/16" | 3/4" | 4 1/8" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 80 mm | 86 mm | 36 mm | 10 mm | 65 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 100 mm | 106 mm | 40 mm | 12 mm | 84 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 130 mm | 135 mm | 49 mm | 14 mm | 109 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 31/32" | 1 29/32" | 11/16" | 3/8" | 1 1/2" | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 17/32" | 2 9/16" | 13/16" | 1/2" | 2 1/8" | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/32" | 3 5/32" | 15/16" | 1/2" | 2 5/8" | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/16" | 3 15/16" | 1 1/8" | 1/2" | 3 1/4" | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 50 mm | 49 mm | 18 mm | 8 mm | 39 mm | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 64 mm | 66 mm | 20 mm | 10 mm | 55 mm | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 80 mm | 81 mm | 24 mm | 10 mm | 67 mm | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 100 mm | 100 mm | 28 mm | 12 mm | 83 mm | Polypropylene | Black | Not Rated to 175° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 1/8" | 2 5/8" | 7/8" | 1/2" | 1 3/4" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 15/16" | 3 3/16" | 1" | 1/2" | 2 1/2" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 4 15/16" | 3 7/8" | 1 1/8" | 5/8" | 2 13/16" | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6 5/16" | 4 1/16" | 1 1/4" | 3/4" | 3 5/32" | Phenolic | Black | Not Rated to 230° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 80 mm | 67 mm | 22 mm | 10 mm | 52 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 100 mm | 81 mm | 26 mm | 12 mm | 63 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 125 mm | 99 mm | 28 mm | 14 mm | 80 mm | Phenolic | Black | Not Rated to 230° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 1/4" | 5" | 1 1/8" | 1/2" | 3 23/32" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 6 9/32" | 1 5/16" | 5/8" | 4 17/32" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 6 13/32" | 1 1/2" | 3/4" | 4 21/32" | Phenolic | Black | 0° F to 210° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Indexing Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 75 mm | 90 mm | 24 mm | 16 mm | 90 mm | Black-Oxide Steel | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 110 mm | 90 mm | 30 mm | 20 mm | 90 mm | Black-Oxide Steel | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 165 mm | 90 mm | 36 mm | 24 mm | 90 mm | Black-Oxide Steel | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Recessed-Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 5/32" | 2 11/16" | 1" | 1/2" | 2 17/32" | Nylon | Black | Not Rated to 190° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 15/16" | 3 7/16" | 1 3/16" | 1/2" | 3 3/16" | Nylon | Black | Not Rated to 190° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4 29/32" | 4 15/32" | 1 7/16" | 5/8" | 4 1/32" | Nylon | Black | Not Rated to 190° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 80 mm | 69 mm | 26 mm | 10 mm | 65 mm | Nylon | Black | Not Rated to 190° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 125 mm | 113 mm | 37 mm | 14 mm | 103 mm | Nylon | Black | Not Rated to 190° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Hole

Lever Handles

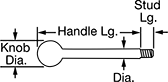

Threaded Stud with Revolving Handle

| |

Knob | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Stud Lg. | Handle Lg. | Dia. | Dia. | Material | Color | Stud Material | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 7/16" | 1 1/2" | 3/8" | 1" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 7/8" | 1/2" | 1 1/4" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 9/16" | 2 3/8" | 5/8" | 1 9/16" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 13/16" | 3 1/16" | 13/16" | 2" | Phenolic | Black | Steel | 0 | 300 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 11 mm | 38 mm | 10 mm | 25 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 48 mm | 13 mm | 32 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 14 mm | 61 mm | 16 mm | 40 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 21 mm | 78 mm | 20 mm | 50 mm | Phenolic | Black | Steel | 0 | 300 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push-On Tapered Lever Handles

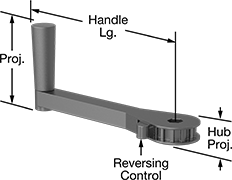

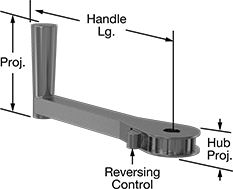

Ratcheting Unthreaded Through-Hole-Mount Crank Handles

|  |

Hex Hole | Round Hole with Keyway |

| |

Square Hole |

Square Hole |

Hex Hole |

Round Hole with Keyway |

Keyway | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Hub Projection | Hole Wd. | Hole Dia. | Wd. | Dp. | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hex Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1 1/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Hole with Keyway | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 1/2" | 1/8" | 1/16" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 5/8" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 3/4" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 1" | 1/4" | 1/8" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 3/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

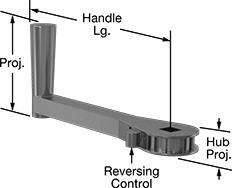

Adjustable-Position Threaded-Hole-Mount Crank Handles

Thread | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Handle Lg. | Projection | Hub Projection | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 7/16" | 2 1/16" | 2 19/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 27/32" | 2 1/16" | 3" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

-1607697253-p9@halfx_637432724644783048.png?ver=ImageNotFound)

--263ad7128161610655044-p9@halfx_637462302512265131.png?ver=ImageNotFound)