About Installing Blind Rivets

More

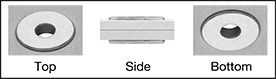

Flush-Mount-on-Both-Sides Blind Rivets

For a flush finish on both sides of the material, install these rivets in countersunk holes. No portion of the mandrel is left behind after installation, creating a through-hole. They have a zinc-plated finish that provides mild corrosion resistance. Use to fasten material when you only have access to one side.

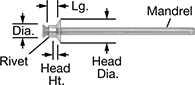

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Countersink Angle | Shear Strength, lbs. | Tensile Strength, lbs. | Material | Pkg. Qty. | Pkg. | |

1/8" Dia. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.059"-0.079" | 0.098" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 000000 |

| 0.079"-0.098" | 0.11" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.098"-0.118" | 0.13" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.118"-0.138" | 0.15" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.138"-0.157" | 0.169" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.157"-0.177" | 0.189" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.177"-0.197" | 0.209" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |

| 0.197"-0.217" | 0.228" | 0.129"-0.134" | No. 29 | 0.216" | 0.039" | 120° | 180 | 150 | Zinc-Plated Steel | 50 | 000000000 | 00000 |