About Rod Ends

More

About Nuts, Materials, and Finishes

More

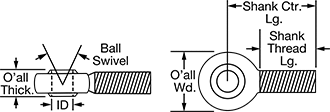

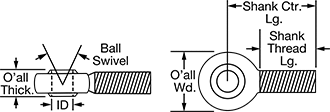

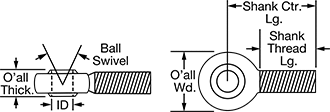

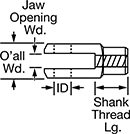

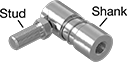

Ball Joint Rod Ends

Made of steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They don’t come lubricated, so you’ll need to lubricate during installation and on an ongoing basis.

Zinc-plated steel rod ends provide moderate corrosion resistance.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

Ball Joints | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 14° | 16mm | 8mm | 33mm | 20mm | 1,150 | Zinc-Plated Carbon Steel | 00000000 | 000000 | |

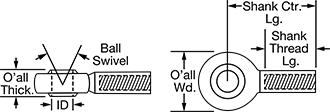

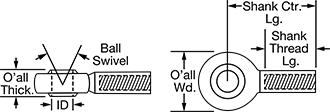

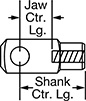

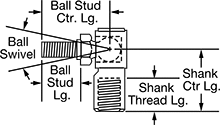

Internally Threaded Ball Joint Rod Ends

Made of steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. They don’t come lubricated, so you’ll need to lubricate them during installation and on an ongoing basis.

Zinc-plated steel rod ends provide moderate corrosion resistance.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

Ball Joints | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 14° | 16mm | 8mm | 27mm | 14mm | 1,550 | Zinc-Plated Carbon Steel | 00000000 | 000000 | |

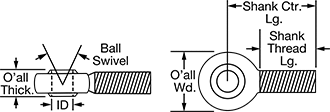

Internally Threaded Lubrication-Free Ball Joint Rod Ends

A carbon fiber-reinforced insert or PTFE liner reduces wear, handles shock loads, and eliminates the need for lubrication. Made of steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. All are zinc plated, so they resist corrosion for a short time before the finish is consumed and the steel is exposed.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 14° | 16mm | 8mm | 27mm | 14mm | 3,650 | Zinc-Plated Chrome-Moly Steel | Right Hand | 00000000 | 000000 |

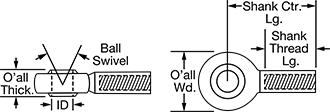

Lubrication-Free Ball Joint Rod Ends

A carbon fiber-reinforced insert or PTFE liner reduces wear, handles shock loads, and eliminates the need for lubrication. Made of steel, these rod ends generally handle higher loads than stainless steel, aluminum, and nylon rod ends. All are zinc plated, so they resist corrosion for a short time before the finish is consumed and the steel is exposed.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 14° | 16mm | 8mm | 33mm | 20mm | 2,800 | Zinc-Plated Alloy Steel | 00000000 | 000000 |

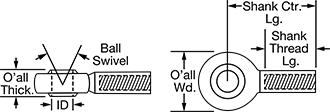

Extended-Life Ball Joint Rod Ends

Seals keep out dirt and an oil-embedded foam insert slowly releases lubricant for a long life. You can remove the insert to add more oil if it starts to run dry. These rod ends have an eyelet and a ball that swivels to support angular misalignment. Made of zinc-plated steel, they have moderate corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 22° | 16mm | 9mm | 33mm | 20mm | 1,150 | Zinc-Plated Carbon Steel | 0000000 | 000000 |

Internally Threaded Corrosion-Resistant Ball Joint Rod Ends

Made of stainless steel, these rod ends provide excellent corrosion resistance. A PTFE liner allows smooth ball rotation and eliminates the need for lubrication.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 22° | 16mm | 8mm | 27mm | 14mm | 920 | 303 Stainless Steel | 0000000 | 000000 |

Corrosion-Resistant Ball Joint Rod Ends

Made of stainless steel, these rod ends provide excellent corrosion resistance. A PTFE liner allows smooth ball rotation and eliminates the need for lubrication.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Material | Choose a Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 22° | 16mm | 8mm | 33mm | 20mm | 910 | 303 Stainless Steel | 0000000 | 000000 |

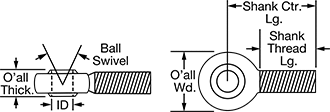

Internally Threaded Chemical-Resistant Ball Joint Rod Ends

Made of impact-resistant nylon, these rod ends withstand corrosion as well as fuels, lyes, and weak acids. They are also 80% lighter than steel rod ends. A self-lubricating nylon ball provides maximum abrasion resistance and eliminates the need for lubrication.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Temp. Range, °F | Material | Specifications Met | Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 15° | 18mm | 6mm | 27mm | 10mm | 65 | -20° to 175° | Nylon Plastic | ISO 12240-4 | Right Hand | 00000000 | 000000 |

Chemical-Resistant Ball Joint Rod Ends

Made of impact-resistant nylon, these rod ends withstand corrosion as well as fuels, lyes, and weak acids. They are also 80% lighter than steel rod ends. A self-lubricating nylon ball provides maximum abrasion resistance and eliminates the need for lubrication.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Temp. Range, °F | Material | Specifications Met | Shank Thread Direction | Each | |

| M5 × 0.8 mm | 5mm | 15° | 18mm | 8mm | 33mm | 19mm | 15 | -20° to 175° | Nylon Plastic | ISO 12240-4 | Right Hand | 00000000 | 000000 |

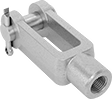

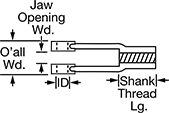

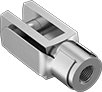

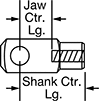

Corrosion-Resistant Clevis Rod Ends

These clevis rod ends offer more corrosion resistance than standard steel clevis rod ends. Also called yoke-end linkages, they support pivoting movement along one axis when threaded onto shafts, rods, valve pistons, and other assemblies.

Stainless steel rod ends offer excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Jaw Opening Wd. | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | Jaw Center Lg. | Tensile Strength, psi | Includes | Shank Thread Direction | Each | |

316 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 5mm | 11mm | 40mm | 14mm | 25mm | 80,000 | Clevis Pin, Cotter Pin | Right Hand | 0000000 | 00000 |

Chemical-Resistant Clevis Rod Ends

In addition to offering superior chemical resistance, these lightweight, fiber-reinforced nylon rod ends also reduce noise and vibration. Also called yoke-end linkages, they support pivoting movement along one axis when threaded onto shafts, rods, valve pistons, and other assemblies.

| Shank Thread Size | ID | Jaw Opening Wd. | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | Jaw Center Lg. | Tensile Strength, psi | Temp. Range, °F | Includes | Shank Thread Direction | Specifications Met | Each | |

Nylon Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 6mm | 12mm | 24mm | 9mm | 12mm | 34,000 | -20° to 175° | Clevis Pin, Retaining Clip | Right Hand | DIN 71752 | 0000000 | 000000 |

Easy-Adapt Clevis Rod Ends

Make quick adjustments to these rod ends by inserting and releasing the clevis pins without the need to bend them into place. Also called yoke-end linkages, they support pivoting movement along one axis when threaded onto shafts, rods, valve pistons, and other assemblies. All are zinc-plated steel for moderate corrosion resistance.

| Shank Thread Size | ID | Jaw Opening Wd. | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | Jaw Center Lg. | Tensile Strength, psi | Includes | Shank Thread Direction | Specifications Met | Each | |

Zinc-Plated Carbon Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 5mm | 10mm | 20mm | 10mm | 10mm | 60,000 | Snap-On Spring Clevis Pin | Right Hand | DIN 71752 | 0000000 | 00000 |

| M5 × 0.8 mm | 5mm | 5mm | 10mm | 30mm | 10mm | 20mm | 60,000 | Snap-On Spring Clevis Pin | Right Hand | DIN 71752 | 0000000 | 0000 |

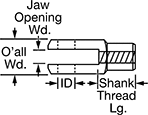

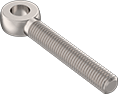

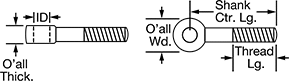

Corrosion-Resistant Fully Threaded Rod End Bolts

These rod end bolts are good for wet and corrosive environments—for maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

303 and 304 stainless steel rod end bolts won't rust in humid, wet, and washdown environments. They're stronger than brass bolts and nearly as strong as steel. They will rust when exposed to salt water and chemicals, however. ASTM rod end bolts meet a standard for material.

DIN 444 rod end bolts meet an international standard for rod end dimensions.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Each | |

Right-Hand Threaded Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel | |||||||||

| M5 × 0.8 mm | 5mm | 12mm | 25mm | 16mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

| M5 × 0.8 mm | 5mm | 12mm | 35mm | 21mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

| M5 × 0.8 mm | 5mm | 12mm | 50mm | 36mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

| M5 × 0.8 mm | 5mm | 12mm | 60mm | 46mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

Left-Hand Threaded Shank | |||||||||

303 Stainless Steel | |||||||||

| M5 × 0.8 mm | 5mm | 12mm | 25mm | 16mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

| M5 × 0.8 mm | 5mm | 12mm | 30mm | 16mm | 6mm | 90,000 | ASTM A582, DIN 444 | 00000000 | 00000 |

Fully Threaded Rod End Bolts

For maximum mounting flexibility, cut the fully threaded shaft to whatever length you need. Also known as swing bolts and eyebolts, rod end bolts have no moving parts. They're designed to make pivoting or hinge movements in applications that don't need to compensate for misalignment.

Partially Threaded Rod End Bolts

Create pivoting connections in applications that require high shear strength—the partially threaded shank of these rod end bolts withstands more side force than a fully threaded shank. Also known as swing bolts and eyebolts, they are used to create hinges, turnbuckles, and tie downs. Unlike ball joint rod ends, these rod end bolts are made from a single piece of metal, so they wear down more slowly and have a more controlled swing. However, because they do not have a moving ball joint, they do not compensate for angular misalignment.

Made from steel, they are stronger and more wear resistant than stainless steel rod end bolts, but they are not as corrosion resistant. Rod end bolts with a black-oxide finish have a dark, matte coating that keeps the steel from rusting in dry environments.

Rod end bolts that meet DIN 444 adhere to international dimensional standards, ensuring they are compatible with other parts and tools.

| Shank Thread Size | ID | O'all Wd. | Shank Center Lg. | Shank Thread Lg. | O'all Thick. | Tensile Strength, psi | Specifications Met | Material | Each | |

Right-Hand Threaded Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 5mm | 12mm | 50mm | 16mm | 6mm | 75,000 | DIN 444 | Black-Oxide Carbon Steel | 00000000 | 000000 |

| M5 × 0.8 mm | 5mm | 12mm | 75mm | 16mm | 6mm | 75,000 | DIN 444 | Black-Oxide Carbon Steel | 00000000 | 00000 |

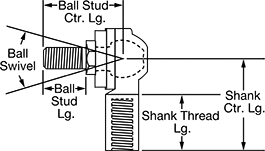

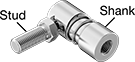

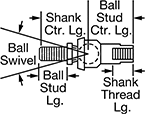

Internally Threaded Ball Joint Linkages

Able to stand up to frequent use, these linkages offer excellent wear resistance. They consist of ball joint rod ends with a ball stud attached to simplify mounting. The stud is machined to fit perfectly inside its housing and swivel in all directions—good for clutches, throttles, and shift control rods.

Linkages with seal have a seal to keep lubricant in and dirt out. Those with a blended rubber seal will require ongoing lubrication.

Shank | Ball Stud | Right-Hand Threaded Ball Stud | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Center Lg. | Thread Lg. | Thread Size | Center Lg. | Lg. | Max. Ball Swivel | Static Radial Load Cap., lbs. | Material | Each | |

Ball Joint Linkages with Blended Rubber Seal | ||||||||||

Right-Hand Threaded Shank | ||||||||||

| M5 × 0.8 mm | 30mm | 16mm | M5 × 0.8 mm | 25mm | 10mm | 34° | 260 | Zinc | 0000000 | 000000 |

Left-Hand Threaded Shank | ||||||||||

| M5 × 0.8 mm | 30mm | 16mm | M5 × 0.8 mm | 25mm | 10mm | 34° | 260 | Zinc | 0000000 | 00000 |

Quick-Install Ball Joint Linkages

A spring-loaded sleeve allows for rapid assembly and disassembly. The stud is machined to fit perfectly inside its housing and swivel in all directions—good for light mechanical components and controls.

Shank | Ball Stud | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Center Lg. | Thread Lg. | Thread Size | Center Lg. | Lg. | Max. Ball Swivel | Static Radial Load Cap. | Material | Ball Stud Thread Direction | Each | |

Right-Hand Threaded Shank | |||||||||||

External Spring | |||||||||||

| M5 × 0.8 mm | 23mm | 11mm | M5 × 0.8 mm | 22mm | 11mm | 30° | Not Rated | Zinc-Plated Carbon Steel | Right Hand | 0000000 | 00000 |

Corrosion-Resistant Quick-Install Ball Joint Linkages

Made of stainless steel, these ball joint linkages offer more corrosion resistance than steel ball joint linkages. A spring-sleeve allows for rapid assembly and disassembly. The stud is machined to fit perfectly inside its housing and swivel in all directions—good for light mechanical components and controls. These ball joint linkages don't come lubricated, so you'll need to lubricate during installation and on an ongoing basis.

Shank | Ball Stud | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Center Lg. | Thread Lg. | Thread Size | Center Lg. | Lg. | Max. Ball Swivel | Static Radial Load Cap. | Material | Ball Stud Thread Direction | Each | |

Right-Hand Threaded Shank | |||||||||||

External Spring | |||||||||||

| M5 × 0.8 mm | 23mm | 11mm | M5 × 0.8 mm | 22mm | 11mm | 30° | Not Rated | 18-8 Stainless Steel | Right Hand | 0000000 | 000000 |

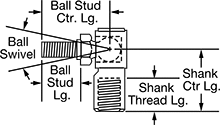

Internally Threaded Inline Ball Joint Linkages

Use these linkages to create inline pivoting connections. The ball-and-socket design allows the ball stud to swivel. All have a liner (also known as a boot) that not only keeps out contaminants, but also acts as a cushion to reduce vibration.

Linkages come lubricated, so you won’t need to lubricate them at installation. Zinc alloy linkages will require ongoing lubrication.

Shank | Ball Stud | Right-Hand Threaded Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Center Lg. | Thread Lg. | Thread Size | Center Lg. | Lg. | Max. Ball Swivel | Static Radial Load Cap. | Material | Lubrication | Ball Stud Thread Direction | Each | |

| M5 × 0.8 mm | 24mm | 12mm | M5 × 0.8 mm | 22mm | 8mm | 25° | Not Rated | Zinc Alloy | Lubricated | Right Hand | 0000000 | 000000 |

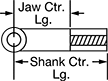

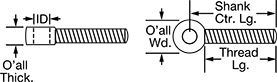

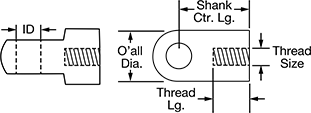

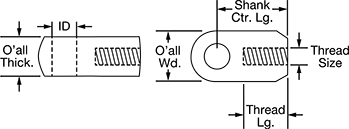

Rod End Nuts

Attach these nuts to rods, pipes, and tubes to make pivoting and hinge movements where misalignment is not a concern. They’re often used to control air- and hydraulic-powered arms as well as other components in power transmission systems. Made of zinc-plated steel, these nuts resist being dislodged. They’re heavy, however, and may corrode over time as the plating wears down.

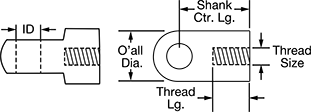

| Shank Thread Size | ID, mm | Overall Diameter, mm | Shank Center Length, mm | Shank Thread Length, mm | Tensile Strength | Material | Each | |

Right-Hand Threaded Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 6.1 | 10 | 16 | 8 | Not Rated | Zinc-Plated Steel | 0000000 | 00000 |

| Shank Thread Size | ID, mm | Overall Width, mm | Overall Thickness, mm | Shank Center Length, mm | Shank Thread Length, mm | Tensile Strength | Material | Each | |

Right-Hand Threaded Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| M5 × 0.8 mm | 8.1 | 15 | 10 | 16 | 8 | Not Rated | Zinc-Plated Steel | 0000000 | 00000 |

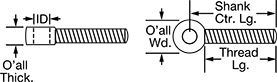

Corrosion-Resistant Rod End Nuts

Made of stainless steel for excellent corrosion resistance, these nuts make pivoting and hinge movements where misalignment is not a concern. Attach them to rods, pipes, and tubes to control air- and hydraulic-powered arms as well as other components in power transmission systems. They have a rubber bushing to reduce noise and vibration.

| Shank Thread Size | ID, mm | Overall Diameter, mm | Shank Center Length, mm | Shank Thread Length, mm | Tensile Strength | Material | Each | |

Right-Hand Threaded Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

Round | ||||||||

| M5 × 0.8 mm | 6.1 | 10 | 16 | 8 | Not Rated | 303 Stainless Steel | 0000000 | 00000 |