About Shafts

More

Selecting Compatible Lead Screws and Nuts

More

Tight-Tolerance Multipurpose Oil-Hardening O1 Tool Steel Rods

- Yield Strength: 50,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Rockwell C65

- Fabrication: Hot Rolled

- Specifications Met: ASTM A681

Ready for turning in a lathe, these rods are precision ground to a tight diameter tolerance. They’re also known as drill rod. Often used for dies, punches, and gauges, O1 tool steel is an oil-hardening material that resists wear and abrasion. It can also be surface hardened with heat treating for added wear resistance. These rods have been manufactured to meet ASTM A681 standards for performance and quality.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance Easy-to-Machine W1 Tool Steel Rods

- Yield Strength: 50,000 psi

- Hardness: Rockwell B95 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C65

- Fabrication: Hot Rolled

- Specifications Met: ASTM A686

Made with lower amounts of alloy elements than other tool steels, these W1 rods are highly machinable. Also called drill rods, they are precision ground and held to strict diameter and straightness tolerances. They’re ready to be turned on a lathe. These rods are decarb-free, which means any surface flaws created during the manufacturing process have been removed. This makes them more machinable and leads to better results from heat treating or finishing. You can harden the surface with heat treating for added wear resistance or water harden for added strength. These rods are often used to make hammers, files, and reamers. All have been manufactured to meet ASTM A686 standards for quality and performance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Multipurpose 304 Stainless Steel

From cookware to chemical-processing equipment, 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

304/304L stainless steel contains less carbon than standard 304 for better weldability.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 30,000 psi

- Hardness: Rockwell B75 (Medium)

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A276

Easy-to-Machine 303 Stainless Steel

Widely used for fabricating fittings and fasteners, 303 stainless steel machines quickly without sticking to cutting tools. It maintains its corrosion resistance in temperatures up to 1500° F.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 25,000 psi

- Hardness:

Inch Sizes: Rockwell B77 (Medium)

Metric Sizes: Rockwell B85 (Medium) - Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met:

Inch Sizes: ASTM A582

Metric Sizes: EN 10088-3

Corrosion-Resistant 316 Stainless Steel

The addition of molybdenum gives 316 stainless steel excellent corrosion resistance. Use it in a variety of marine and chemical-processing applications. It maintains its corrosion resistance up to the maximum temperature.

316/316L stainless steel contains less carbon than standard 316 for better weldability.

If you don’t see the rod size you’re looking for, please specify a length under additional rod lengths.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength:

Inch Sizes: 30,000 psi

Metric Sizes: 29,000 psi - Hardness:

Inch Sizes: Rockwell B75 (Medium)

Metric Sizes: Rockwell B80 (Medium) - Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met:

Inch Sizes: ASTM A276

- Yield Strength: 30,000 psi

- Hardness: Rockwell B75 (Medium)

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Specifications Met: ASTM A276

To Order: Please specify length in increments of 0.125" within the range listed.

| Dia. | Dia. Tolerance | Fabrication | Max. Temp., °F | Straightness Tolerance | Choose a Length | Per Inch | |

316/316L Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

| 1 11/16" | -0.003" to 0.003" | Cold Worked | 1500° | 1/8" per 5 ft. | 13"-90" | 000000000 | 00000 |

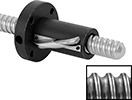

Fast-Travel Ball Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than ball screws with a single thread start. Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. To ensure compatibility, select components that have the same thread size and number of thread starts. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Black-oxide alloy steel ball nuts have mild corrosion resistance.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

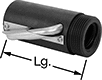

| Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Black-Oxide Alloy Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | 1"-4 | 3 1/8" | 1 11/16" | 2 | 0.5" | 1 9/16"-18 | Rockwell C56 | 4,250 | 0.015" | -65° to 300° | 00000000 | 0000000 |

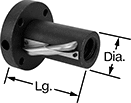

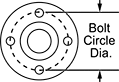

Flange | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | Dia. | Thick. | No. of Thread Starts | Travel Distance per Turn | Bolt Circle Dia. | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Black-Oxide Alloy Steel | ||||||||||||||

| F | 1"-4 | 3 1/8" | 1 11/16" | 2 15/64" | 5/8" | 2 | 0.5" | 2 3/4" | Rockwell C56 | 4,250 | 0.015" | -65° to 300° | 00000000 | 0000000 |

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||

|---|---|---|---|---|---|---|---|

1 11/16" Dia. (Tolerance: -0.002" to 0") | |||||||

| 12" | -0.062" to 0.062" | 0.012" per ft. | Chamfered | Medium | Brinell 197 | 0000000 | 000000 |

| 24" | -0.062" to 0.062" | 0.012" per ft. | Chamfered | Medium | Brinell 197 | 0000000 | 00000 |

| 36" | -0.062" to 0.062" | 0.012" per ft. | Chamfered | Medium | Brinell 197 | 0000000 | 000000 |

| 48" | -0.062" to 0.062" | 0.012" per ft. | Chamfered | Medium | Brinell 197 | 0000000 | 000000 |

| 72" | -0.062" to 0.062" | 0.012" per ft. | Chamfered | Medium | Brinell 197 | 0000000 | 000000 |

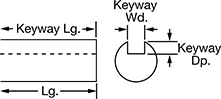

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. 1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | ||||||||||

1 11/16" Dia. (Tolerance: -0.003" to 0") | ||||||||||

| 12" | 12" | 0.375" | 3/16" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 24" | 24" | 0.375" | 3/16" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 36" | 36" | 0.375" | 3/16" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 72" | 72" | 0.375" | 3/16" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |