Filter by

Axle Shape

Bearing Type

Maximum Temperature

Weight Capacity

Roller Width

Ball Bearing Material

Motorized

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Minimum Temperature

Axle Grip Type

Ball Bearing Finish

Bearing Finish

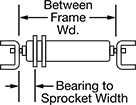

Bearing-to-Sprocket Width

Sprocket Center-to-Center Width

Bearing Material

Roller Material

Large-Diameter Conveyor Rollers

Hex Axle

Hex Axle

Steel rollers are stronger than aluminum rollers.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

11/16" Hex Axle | |||||||

2 1/2" Dia. Steel Roller | |||||||

| 31" | 30 7/16" | 11 | 640 | 33" | -40° to 300° | 0000000 | 000000 |

Sprocketed Conveyor Rollers

Replace rollers on a chain-driven conveyor.

Roller | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | For ANSI Chain No. | Wd. | Gauge | Cap., lbs. | No. of Sprockets | No. of Teeth per Sprocket | Bearing-to-Sprocket Wd. | Sprocket Ctr.-to-Ctr. Wd. | O'all Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||||||

1.9" Dia. Steel Roller | ||||||||||||

| 31" | 40 | 30 7/16" | 9 | 280 | 2 | 18 | 1 1/8" | 1 1/8" | 32 1/4" | -40° to 300° | 0000000 | 0000000 |

| 31" | 50 | 30 7/16" | 9 | 290 | 2 | 15 | 1 1/8" | 1 1/8" | 32 1/4" | -40° to 300° | 00000000 | 000000 |