Filter by

System of Measurement

Diameter

Attachment Type

Material

Flexibility

Weight Capacity

Fitting Type

Application

Wire Rope Coating

Military Specification

Wire Rope Construction

Wire Rope Core Type

RoHS

DFARS Specialty Metals

Thread Size

Screw Size

Performance

Lubrication

Recommended Pulley/Drum Diameter

Wire Rope

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64" | 100 | 7 × 7 Strand Core | 3 1/4" | Yes | 5 , 10 , 25 , 50 , 100 , 250 , 500 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

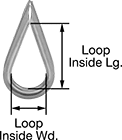

Light Duty Wire Rope Thimbles—Not for Lifting

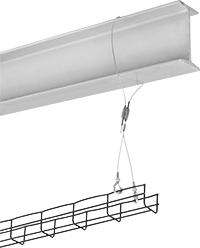

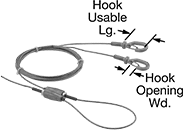

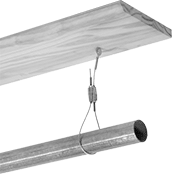

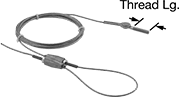

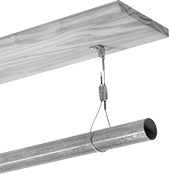

Adjustable-Loop-to-Twin-Hook Lanyards—Not for Lifting

Adjustable-Loop-to-Stud Lanyards—Not for Lifting

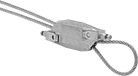

Quick-Adjust Wire Rope Clamps—Not for Lifting

For Wire Rope | Clamp | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

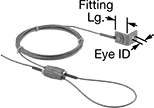

Dia. | Construction | Lg. | Wd. | Thk. | Wt. Cap., lb. | Loop Adjustment Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64", 3/32" | 1 × 19 Strand Core 7 × 7 Strand Core | 1 5/16" | 1 1/4" | 3/8" | 100 | Hex Key | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

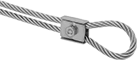

Easy-Install Wire Rope Clamps—Not for Lifting

|

With Nut and Bolt |

For Wire Rope | Clamp | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Lg. | Wd. | Thk. | Wt. Cap. | No. of Bolts | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 3/8" | 7/16" | 3/8" | Not Rated | 2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 1 3/8" | 7/16" | 3/8" | Not Rated | 2 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Semi-Flexible Wire Rope

Cast Wire Rope Clamps—Not for Lifting

For Wire Rope | Clamp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

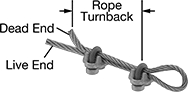

Dia. | Construction | Number of Clamps Required | Rope Turnback | Wd. | Ht. | Thk. | Fabrication | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/64" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 | 2 1/4" | 39/64" | 11/16" | 21/64" | Cast | 3 | 85% | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||