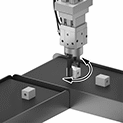

Air-Powered Rotary Grippers

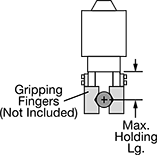

These grippers pick up a product and turn it 180° before releasing. Use them with gripping fingers to lift and move items in pick-and-place applications. They have two air ports: one to move the jaws open and another to move them closed. The jaws can grip items from the outside as well as the inside.

Finger blanks (sold separately) come ready to mount, so you can make custom fingers without starting from scratch. Just machine the blank’s gripping end to create fingers that will securely grip your specific parts.

When used in pairs, individual blanks have a symmetrical design that’s suitable for most applications.

Uncut pair blanks can be cut off center, making them good for applications where symmetrical fingers may hit nearby objects, such as when moving around machine spindles and parts trays during machine tending.

Aluminum blanks are lightweight and resist rusting in wet environments. They’re softer than steel blanks, making them easier to machine and less likely to scratch your parts.

Steel blanks are stronger and more durable than aluminum blanks, so they’re less likely to break if they hit a nearby object. You can harden them for even more strength and durability.

Warning: Never use to lift people or items over people.

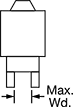

Jaw | Wd. | Overall | Port | Temp., °F | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotation | External Gripping Force | Internal Gripping Force | Wd., mm | Dp., mm | Max., mm | Min., mm | Max. Holding Lg., mm | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Gender | Housing Material | Min. | Max. | Each | |

Parallel Grippers with Forced Air Jaw Return—Steel Jaws | |||||||||||||||||||

| 180° | 2.25 lbs. @ 72.5 psi | 3.6 lbs. @ 72.5 psi | 4 | 5 | 15.2 | 11.2 | 50 | 107 | 41 | 47 | 100 | M5 × 0.8 | Metric | Female | Aluminum | 45° | 140° | 0000000 | 0000000 |

| 180° | 14.61 lbs. @ 72.5 psi | 22.48 lbs. @ 72.5 psi | 10 | 12 | 33.3 | 19.3 | 100 | 180 | 70 | 84 | 100 | M5 × 0.8 | Metric | Female | Aluminum | 45° | 140° | 0000000 | 000000 |

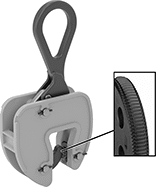

Vertical-Lift with 90° Tilt Plate-Lifting Clamps

Clamps can take a metal plate that is stacked horizontally and tilt it up 90° so it can be lifted in a vertical position. After lifting, clamps can place the plate back down in the original position (plate can not be flipped over).

Automatic close clamps close under their own weight; as the load increases, so does the grip. Clamps with a lock stay closed to prevent accidental release.

Manual open with lock and remote release clamps have a pull chain so they can open remotely when they are not under load. They lock when open for easy loading.

Warning: Never use to lift people or items over people.

Clamps | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Thick. | Overall | Eye | Replacement Grippers | Replacement Lifting Eyes | ||||||||||||

| Cap., lbs. | Min. | Max. | Grip Type | Opening Ht. | Wd. | Ht. | Lg. | Wd. | For Max. Hardness | Specifications Met | Each | Each | Each | |||

Automatic Close and Manual Open | ||||||||||||||||

| 1,100 | 1/16" | 5/8" | Teeth | 2 3/16" | 4" | 11 13/16" | 2 3/4" | 2" | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 |

Automatic Close with Lock and Manual Open with Lock and Remote Release | ||||||||||||||||

| 6,600 | 1/16" | 1 1/4" | Teeth | 4 3/8" | 7 1/4" | 14 3/8" | 3 1/2" | 2" | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 |

| 11,000 | 1/16" | 1 1/2" | Teeth | 5" | 8 7/8" | 16" | 3 1/2" | 2 1/2" | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 |

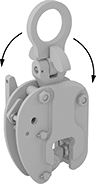

Vertical-Lift with 180° Flip Plate-Lifting Clamps

Take the strain out of manually standing up stacked plates before lifting them—these clamps have a full 180° range of motion. They can raise the plate from stacked to standing, then lift it vertically, so you can move the plate where you need it. When you're ready to put the plate down again, they can place it on its opposite side.

To make sure the grip is secure for safe lifting, only use these clamps within their weight capacity range.

Automatic close and manual open are quick and easy to use because they don’t have a locking mechanism, but they are less secure than clamps with a lock. These clamps close under their own weight—as the load increases, so does the grip. To open, first set your plate down. Then, press down on the shackle until the cam retracts and remove the plate.

Automatic close with lock and automatic open with lock are more secure than clamps without a lock. They close under their own weight—as the load increases, so does the grip. These clamps must be unlocked before they will automatically open and release the plate.

Manual close and manual open use a screw to grip the plate, so you can fit a range of plate thicknesses. As the load gets heavier, the bite of the cam increases, which gives the clamp a secure grip on the plate. To open, first set your plate down. Then, press down on the shackle until the cam retracts and remove the plate.

Rigid clamps lift vertical plates straight up and down but lose their grip when angled. Make sure your plate is fully vertical, and the bottom edge is resting on the ground, before lifting.

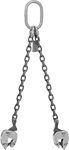

Pivoting clamps safely lift vertical loads at an angle. Also known as sideloading clamps, they are more flexible than rigid clamps. Use them individually or in pairs with a two-leg sling (not included) to lift longer plates.

Style A have wear indicator grooves that let you know when the cam should be replaced—if any teeth are flattened, chipped, or dulled between the grooves, it’s time to swap it out. Style B can also lift I-beams. Style C come with a two-leg sling to lift large or flexible plates.

Warning: Never use to lift people or items over people.

Clamps | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Thick. | Overall | Eye | Replacement Grippers | Replacement Lifting Eyes | |||||||||||||||

| Style | Cap., lbs. | Min. | Max. | Grip Type | Opening Ht. | Wd. | Ht. | Dia. | Lg. | Wd. | Movement | For Max. Hardness | Specifications Met | Each | Each | Each | |||

Automatic Close and Manual Open | |||||||||||||||||||

| A | 100-1,000 | 1/16" | 5/8" | Teeth | 2 3/16" | 4" | 9 1/2" | __ | 2 3/4" | 2" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 |

| A | 200-2,000 | 1/16" | 3/4" | Teeth | 3 1/16" | 4 3/4" | 11 1/4" | __ | 3 1/16" | 2 1/16" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

| A | 200-2,000 | 3/4" | 1 3/8" | Teeth | 3 5/8" | 5 7/8" | 11 1/4" | __ | 3 1/16" | 2 1/16" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 00000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| A | 600-6,000 | 1/16" | 1" | Teeth | 3 9/16" | 6" | 14" | __ | 3 13/16" | 3" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| B | 100-1,000 | 1/16" | 5/8" | Teeth | 2 1/8" | 4" | 9 1/2" | __ | 2 5/8" | 2" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

| B | 200-2,000 | 1/16" | 3/4" | Teeth | 2 5/8" | 4 3/4" | 11 5/16" | __ | 3 1/16" | 2 1/16" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

| B | 400-4,000 | 1/16" | 7/8" | Teeth | 3 9/16" | 5 1/8" | 12 1/8" | __ | 3 5/16" | 2 1/4" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| B | 600-6,000 | 1/16" | 1" | Teeth | 3 7/16" | 6" | 15 1/16" | __ | 3 13/16" | 3" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

| C | 100-1,000 | 1/16" | 5/8" | Teeth | 2 7/8" | 4" | 7 1/2" | __ | 6" | 3" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 |

| C | 200-2,000 | 1/16" | 3/4" | Teeth | 3 5/8" | 4 3/4" | 9 1/4" | __ | 6" | 3" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 |

Automatic Close with Lock and Automatic Open with Lock | |||||||||||||||||||

| D | 100-1,000 | __ | 1 3/8" | Teeth | 2 3/4" | 5 7/8" | 11 1/2" | 2 1/4" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 0000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| D | 200-2,000 | __ | 1 3/8" | Teeth | 2 3/4" | 5 7/8" | 11 1/2" | 2 1/4" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 0000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| Each | Pair | Each | |||||||||||||||||

| D | 400-4,000 | __ | 1 5/8" | Teeth | 4 1/8" | 8 3/8" | 15 1/4" | 3" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| D | 800-8,000 | __ | 2 1/8" | Teeth | 4 5/8" | 10" | 19" | 3 1/2" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| D | 1,200-12,000 | __ | 2 1/8" | Teeth | 4 5/8" | 10" | 19" | 3 1/2" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| D | 2,000-20,000 | __ | 2 5/8" | Teeth | 5 3/8" | 11 1/8" | 22 1/4" | 4" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| D | 2,400-24,000 | 1/2" | 3 1/8" | Teeth | 6 1/4" | 12 1/2" | 25 3/8" | 4" | __ | __ | Rigid | 450 Brinell, Rockwell C47 | ASME B30.20 | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| Each | Each | Each | |||||||||||||||||

| E | 100-1,000 | __ | 1 3/8" | Teeth | 2 3/4" | 5 7/8" | 13" | 2 1/4" | __ | __ | 90° Pivot | 450 Brinell, Rockwell C47 | ASME B30.20 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| Each | Pair | Each | |||||||||||||||||

| E | 600-6,000 | __ | 1 5/8" | Teeth | 4 1/8" | 8 3/8" | 17 3/8" | 1 5/8" | __ | __ | 90° Pivot | 450 Brinell, Rockwell C47 | ASME B30.20 | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| Each | Each | Each | |||||||||||||||||

| F | 200-2,000 | __ | 3/4" | Teeth | 1 3/4" | 5" | 8 1/2" | 1 9/16" | __ | __ | Rigid | 345 Brinell, Rockwell C37 | ASME B30.20 | 0000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 |

| F | 400-4,000 | __ | 1 3/8" | Teeth | 3 1/16" | 7 1/2" | 13" | 2 3/4" | __ | __ | Rigid | 345 Brinell, Rockwell C37 | ASME B30.20 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| G | 200-2,000 | __ | 3/4" | Teeth | 1 3/4" | 5" | 8 3/4" | 1 9/16" | __ | __ | 45° Pivot | 345 Brinell, Rockwell C37 | ASME B30.20 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 |

| G | 400-4,000 | __ | 3/4" | Teeth | 3 1/16" | 7 1/2" | 14 1/2" | 2 3/4" | __ | __ | 45° Pivot | 345 Brinell, Rockwell C37 | ASME B30.20 | 00000000 | 00000000 | 000000 | 00 | 000000 | 00 |

| H | 2,700-13,200 | __ | 2" | Teeth | 5 5/8" | 11 1/2" | 29" | __ | 6 15/16" | 3 3/4" | 90° Pivot | 300 Brinell, Rockwell C32 | ASME B30.20 | 00000000 | 00000000 | 000000 | 00 | 000000 | 00 |

Manual Close and Manual Open | |||||||||||||||||||

| J | 200-2,000 | 1/16" | 1" | Screw | 2 1/4" | 5 3/8" | 7 7/8" | __ | 2 7/8" | 1 3/4" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 | 000000 | 00 |

| J | 600-6,000 | 1/16" | 2" | Screw | 3 3/4" | 7 7/8" | 10 5/8" | __ | 3 3/8" | 1 7/8" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 |

| J | 1,200-12,000 | 1/16" | 3" | Screw | 4 1/2" | 10" | 14 3/8" | __ | 4 1/2" | 3 3/8" | Rigid | 400 Brinell, Rockwell C43 | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 |

| Repair Kit for Style D 4,000-lb. Capacity Clamps (Includes Bolt, Gripper, Nut, Pins, Spring) | 00000000 | Each | 0000000 |

| Repair Kit for Style D 1,000 to 2,000-lb. Capacity Clamps (Includes Bolt, Gripper, Nut, Pins, Spring) | 00000000 | Each | 000000 |

| Repair Kit for Style D 8,000-lb. Capacity Clamps (Includes Bolt, Gripper, Nut, Pins, Spring) | 00000000 | Each | 000000 |

Nonmarring Vertical-Lift with 180° Flip Plate-Lifting Clamps

Pads on these clamps prevent the grip from biting into the load. They can take a metal plate of any hardness that is stacked horizontally, lift it vertically, and then place it down horizontally on its other side. Clamps close under their own weight; as the load increases, so does the grip. The lock keeps them closed to prevent accidental release. Clamps automatically open and lock when they are not under load so a new plate can be easily inserted. They have an eye that pivots to allow lifting angles up to 15° without reducing the capacity. The eye adjusts to accommodate unbalanced loads.

Warning: Never use to lift people or items over people.

Clamps | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Replacement Grippers | ||||||||||

| Cap., lbs. | For Max. Thick. | Grip Type | Opening Ht. | Wd. | Ht. | Eye Dia. | Specifications Met | Each | Each | ||

Automatic Close with Lock and Automatic Open with Lock | |||||||||||

| 1,100 | 3/8" | Pad | 3 1/4" | 5" | 10" | 1 9/16" | ASME B30.20 | 0000000 | 000000000 | 00000000 | 0000000 |

| 2,200 | 3/4" | Pad | 4 5/16" | 7 1/4" | 12 1/8" | 1 3/16" | ASME B30.20 | 0000000 | 00000000 | 00000000 | 000000 |

Swiveling Gripper Tips for Screws and Threaded Studs

Attach to the end of a screw or threaded stud—the serrated face swivels to grip uneven and angled surfaces. Also known as toggle and swivel-foot pads.

| Dia. | Ht. | Load Capacity, lbs. | Range of Motion | Mounting Hole Thread Size | Each | |

Steel | ||||||

|---|---|---|---|---|---|---|

| 5/8" | 5/8" | 3,900 | 10° | 1/4"-20 | 0000000 | 00000 |

| 11/16" | 3/4" | 5,900 | 10° | 5/16"-18 | 0000000 | 0000 |

| 3/4" | 13/16" | 6,400 | 10° | 3/8"-16 | 0000000 | 0000 |

| 7/8" | 15/16" | 7,000 | 10° | 1/2"-13 | 0000000 | 0000 |

| 1" | 1" | 10,000 | 10° | 5/8"-11 | 0000000 | 0000 |

| 1 1/4" | 1 3/8" | 13,500 | 10° | 3/4"-10 | 0000000 | 00000 |

| 1 5/8" | 1 13/16" | 18,750 | 10° | 1"-8 | 0000000 | 00000 |

Stainless Steel | ||||||

| 5/8" | 5/8" | 5,000 | 10° | 1/4"-20 | 00000000 | 00000 |

| 11/16" | 3/4" | 7,600 | 10° | 5/16"-18 | 00000000 | 00000 |

| 3/4" | 13/16" | 8,250 | 10° | 3/8"-16 | 00000000 | 00000 |

| 7/8" | 15/16" | 9,000 | 10° | 1/2"-13 | 00000000 | 00000 |

| 1" | 1" | 12,900 | 10° | 5/8"-11 | 00000000 | 00000 |

| 1 1/4" | 1 3/8" | 17,400 | 10° | 3/4"-10 | 00000000 | 00000 |

| 1 5/8" | 1 13/16" | 24,200 | 10° | 1"-8 | 00000000 | 00000 |

Swivel-Tip Set-Screw Grippers

Grip angled and uneven surfaces with precision and ease. These grippers thread into either side of your fixture or plate. You can even position them so their serrations are flush with the surface. Adjust their height with a hex key. For a secure hold, clamp your workpiece against them.

Ultra-fine serrations are the most closely spaced for the lightest penetration of the workpiece.

Extra-fine serrations are a little farther apart than ultra-fine serrations, so they penetrate the workpiece slightly more for a firmer hold.

Drive | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Dia. | Ht. | Size | Style | Range of Motion | Load Cap., lbs. | Material | Tip Material | Each | |

Threaded Stud | ||||||||||

Ultra-Fine Serrations | ||||||||||

| 3/8"-16 | 5/32" | 1/2" | 3/16" | Hex | 28° | 1,700 | Steel | Steel | 0000000 | 000000 |

| 3/8"-16 | 5/32" | 1" | 3/16" | Hex | 28° | 1,700 | Steel | Steel | 0000000 | 00000 |

| 3/8"-16 | 5/32" | 2" | 3/16" | Hex | 28° | 1,700 | Steel | Steel | 0000000 | 00000 |

Extra-Fine Serrations | ||||||||||

| 5/8"-16 | 5/16" | 1" | 5/16" | Hex | 28° | 6,000 | Steel | Steel | 0000000 | 00000 |

| 5/8"-16 | 5/16" | 2" | 5/16" | Hex | 28° | 6,000 | Steel | Steel | 0000000 | 00000 |

Swivel-Tip Gripper Screws

The serrated tip swivels to grip uneven and angled surfaces and the threaded stud lets you make quick height adjustments.

Ultra-fine serrations are the most closely spaced for the lightest penetration of the workpiece.

Extra-fine serrations are closer together for less penetration and a lighter hold on the workpiece.

Fine serrations penetrate the workpiece for aggressive holding.

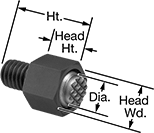

Thread | Head | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Lg. | Dia. | Ht. | Ht. | Wd. | Range of Motion | Load Cap., lbs. | Material | Tip Material | Each | |

Hex with Threaded Stud | |||||||||||

Ultra-Fine Serrations | |||||||||||

| 10-32 | 1/2" | 5/32" | 3/4" | 1/4" | 3/8" | 28° | 1,150 | Steel | Steel | 0000000 | 000000 |

| 1/4"-20 | 1/2" | 1/4" | 13/16" | 5/16" | 7/16" | 28° | 2,400 | Steel | Steel | 0000000 | 00000 |

Extra-Fine Serrations | |||||||||||

| 5/16"-18 | 1/2" | 5/16" | 7/8" | 3/8" | 1/2" | 28° | 2,750 | Steel | Steel | 0000000 | 00000 |

| 3/8"-16 | 1/2" | 3/8" | 1" | 1/2" | 5/8" | 40° | 3,400 | Steel | Steel | 0000000 | 00000 |

Fine Serrations | |||||||||||

| 1/2"-13 | 1" | 1/2" | 1 5/8" | 5/8" | 13/16" | 40° | 5,900 | Steel | Steel | 0000000 | 00000 |

| 5/8"-11 | 1" | 5/8" | 1 11/16" | 11/16" | 15/16" | 34° | 9,900 | Steel | Steel | 0000000 | 00000 |