Filter by

Environment

For Use With

Air Inlet Connection

Air Inlet Location

Air Inlet Gender

Maximum Temperature

Air Inlet Connection Port

Fitting Connection

Export Control Classification Number (ECCN)

DFARS Specialty Metals

RoHS

Specifications Met

Depth

Height

Thread Size

Sanitary Air Knives for Blowers

Airflow | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot Wd. | Slot Dp. | Wd. | Ht. | Dp. | Air Inlet Flange OD | Mounting Fasteners Included | Mounting Hole Thread Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1/32" to 1/8" | 7 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" to 1/8" | 13 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1/32" to 1/8" | 19 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" to 1/8" | 25 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 1/32" to 1/8" | 31 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1/32" to 1/8" | 37 3/16" | 5 13/32" | 3 7/8" | 3.579" | No | 3/8"-16 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

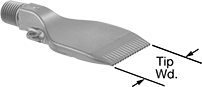

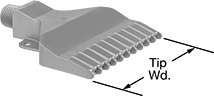

Food and Beverage Wide-Airflow Air Nozzles

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 16 ft³/min @ 75 psi | 1,000 | 83 dBA @ 80 psi | 1 5/8" | 1/16" | 3 3/16" | 145 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 38 ft³/min @ 75 psi | 1,000 | 90 dBA @ 80 psi | 2 3/4" | 3/16" | 3 1/8" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 16 ft³/min @ 75 psi | 1,000 | 83 dBA @ 80 psi | 1 5/8" | 1/16" | 3 3/16" | 145 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 38 ft³/min @ 75 psi | 1,000 | 90 dBA @ 80 psi | 2 3/4" | 3/16" | 3 1/8" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

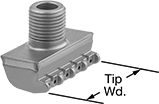

Right-Angle Food and Beverage Wide-Airflow Air Nozzles

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 ft³/min @ 75 psi | 1,000 | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 BSPP Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 ft³/min @ 75 psi | 1,000 | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||