Filter by

Bearing Seal Type

Shaft Diameter

For Load Direction

Static Thrust Load Capacity

Dynamic Thrust Load Capacity

Roller Bearing Type

Mounted Bearing Type

ID

Bearing Construction

Lubrication

Width

Maximum Rotation Speed

Minimum Temperature

Bearing Trade Number

Dynamic Radial Load Capacity

DFARS Specialty Metals

For Housing ID

Static Radial Load Capacity

Extreme-Load Tapered-Roller Thrust Bearings

|

For Shaft Dia. | OD | Thk. | Dynamic Thrust Load Cap., lb. | Max. Rotation Speed, rpm | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2.29" | 0.677" | 12,000 | 10 | 0 to 150 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 2.398" | 0.656" | 14,500 | 10 | 0 to 150 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2.705" | 0.815" | 20,300 | 10 | 0 to 150 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 2.98" | 0.8438" | 20,500 | 10 | 0 to 150 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 3.455" | 0.99" | 28,400 | 10 | 0 to 150 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/16" | 3.823" | 1.121" | 37,500 | 10 | 0 to 150 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Angular Contact Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Material | Dynamic Combined Load Cap., lbf | Max. Rotation Speed, rpm | Lubrication | Contact Angle | Min. | Max. | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 30 | 9 | 1 | Steel | 1,150 | 15,000 | Lubricated | 40° | -20 | 230 | 7200-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 10 | 1 | Steel | 1,650 | 14,000 | Lubricated | 40° | -20 | 230 | 7201-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 11 | 1 | Steel | 1,850 | 24,000 | Lubricated | 40° | -20 | 230 | 7202-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 42 | 13 | 1 | Steel | 3,150 | 11,000 | Lubricated | 40° | -20 | 230 | 7302-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | Steel | 2,350 | 11,000 | Lubricated | 40° | -20 | 230 | 7203-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 47 | 14 | 1 | Steel | 3,950 | 13,000 | Lubricated | 40° | -20 | 230 | 7303-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 14 | 1 | Steel | 3,100 | 9,000 | Lubricated | 40° | -20 | 230 | 7204-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 52 | 15 | 1 | Steel | 4,550 | 8,500 | Lubricated | 40° | -20 | 230 | 7304-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 15 | 1 | Steel | 3,400 | 8,000 | Lubricated | 40° | -20 | 230 | 7205-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 62 | 17 | 1 | Steel | 6,250 | 7,000 | Lubricated | 40° | -20 | 230 | 7305-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 16 | 1 | Steel | 4,850 | 6,300 | Lubricated | 40° | -20 | 230 | 7206-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 72 | 19 | 1 | Steel | 7,650 | 6,000 | Lubricated | 40° | -20 | 230 | 7306-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 17 | 1 | Steel | 6,250 | 5,600 | Lubricated | 40° | -20 | 230 | 7207-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 18 | 1 | Steel | 7,600 | 5,000 | Lubricated | 40° | -20 | 230 | 7208-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 90 | 23 | 1 | Steel | 11,900 | 4,500 | Lubricated | 40° | -20 | 230 | 7308-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 30 | 14 | 1 | Steel | 1,700 | 17,000 | Lubricated | 30° | -40 | 210 | 3200-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 15.9 | 1 | Steel | 2,250 | 15,000 | Lubricated | 30° | -40 | 210 | 3201-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 15.9 | 1 | Steel | 2,500 | 14,000 | Lubricated | 30° | -40 | 210 | 3202-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17.5 | 1 | Steel | 3,200 | 12,000 | Lubricated | 30° | -40 | 210 | 3203-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 47 | 22.2 | 1 | Steel | 4,850 | 11,000 | Lubricated | 30° | -40 | 210 | 3303-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 20.6 | 3 | Steel | 4,450 | 10,000 | Lubricated | 30° | -40 | 210 | 3204-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 52 | 22.2 | 3 | Steel | 5,300 | 9,000 | Lubricated | 30° | -40 | 210 | 3304-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 20.6 | 3 | Steel | 4,850 | 8,500 | Lubricated | 30° | -40 | 210 | 3205-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 62 | 25.4 | 3 | Steel | 7,150 | 7,500 | Lubricated | 30° | -40 | 210 | 3305-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 23.8 | 3 | Steel | 6,700 | 7,500 | Lubricated | 30° | -40 | 210 | 3206-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 27 | 3 | Steel | 8,950 | 6,300 | Lubricated | 30° | -40 | 210 | 3207-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 30.2 | 3 | Steel | 10,600 | 5,600 | Lubricated | 30° | -40 | 210 | 3208-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 90 | 30.2 | 3 | Steel | 11,400 | 4,800 | Lubricated | 30° | -40 | 210 | 3210-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

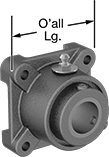

Mounted Tapered-Roller Bearings with Four-Bolt Flange

Overall | Dynamic Load Cap., lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Lg. | Wd. | Flange Thk. | Radial | Thrust | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Cast Iron Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 3 3/4" | 2 13/16" | 1" | 3,800 | 2,000 | 4,400 | Steel | Sealed | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 3/8" | 3 1/2" | 1 3/16" | 7,850 | 2,550 | 3,300 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 5 5/8" | 3 5/8" | 1 3/16" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5 5/8" | 3 5/8" | 1 3/16" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 6 7/8" | 4 3/16" | 1 1/2" | 11,600 | 3,450 | 2,400 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 7 3/4" | 4 11/16" | 1 5/8" | 12,300 | 5,150 | 2,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 9 1/4" | 5 1/4" | 1 7/8" | 19,600 | 5,150 | 1,600 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 10 1/4" | 6 1/2" | 2 1/8" | 26,900 | 6,900 | 1,500 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 4 5/8" | 3 1/16" | 1 1/16" | 6,100 | 2,550 | 3,800 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 5 5/8" | 3 5/8" | 1 3/16" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Face-Mount Crossed-Roller Bearings

Combined Load Cap., lbf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Sealed with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 52 | 8 | 650 | 540 | 1,900 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 70 | 12 | 1,700 | 1,850 | 1,300 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 80 | 12 | 1,900 | 2,350 | 1,100 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 95 | 15 | 3,850 | 4,650 | 900 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 120 | 15 | 4,500 | 6,200 | 650 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 165 | 22 | 11,400 | 16,100 | 450 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 210 | 25 | 16,500 | 24,200 | 400 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 115 | 240 | 28 | 18,950 | 31,000 | 300 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 295 | 35 | 23,350 | 38,850 | 350 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 380 | 40 | 35,050 | 63,150 | 260 | Lubricated | 0 to 175 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thin-Profile Crossed-Roller Bearings

Combined Load Cap., lbf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Sealed with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 66 | 8 | 1,100 | 1,600 | 700 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 76 | 8 | 1,250 | 1,950 | 500 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 86 | 8 | 1,300 | 2,200 | 510 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 96 | 8 | 1,400 | 2,500 | 460 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 106 | 8 | 1,500 | 2,750 | 375 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 116 | 8 | 1,600 | 3,100 | 350 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 126 | 8 | 1,650 | 3,350 | 300 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 136 | 8 | 1,750 | 3,700 | 275 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 130 | 146 | 8 | 1,750 | 3,950 | 290 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | 156 | 8 | 1,850 | 4,250 | 270 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 166 | 8 | 1,950 | 4,600 | 250 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 166 | 13 | 5,200 | 10,050 | 230 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 170 | 196 | 13 | 5,250 | 10,400 | 220 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 206 | 13 | 5,500 | 11,150 | 205 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 190 | 216 | 13 | 5,550 | 11,550 | 195 | Lubricated | 0 to 175 | Four Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 226 | 13 | 5,800 | 12,250 | 175 | Lubricated | 0 to 175 | Lubrication Groove, Lubrication Hole | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Crossed-Roller Bearings

Combined Load Cap., lbf | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial, Thrust, and Moment Load—Sealed with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 36 | 8 | 650 | 540 | 2,100 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 55 | 10 | 1,700 | 1,850 | 1,400 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 65 | 10 | 1,900 | 2,350 | 1,100 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 80 | 13 | 3,850 | 4,600 | 900 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 90 | 13 | 4,200 | 5,400 | 800 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 100 | 13 | 4,500 | 6,200 | 700 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 120 | 16 | 7,200 | 9,700 | 600 | Lubricated | 0 to 210 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 130 | 16 | 7,400 | 10,500 | 540 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 150 | 20 | 11,400 | 16,200 | 480 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 160 | 20 | 11,750 | 17,400 | 440 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 180 | 25 | 16,500 | 24,250 | 400 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 260 | 25 | 20,700 | 37,950 | 260 | Lubricated | 0 to 245 | Lubrication Groove, Two Lubrication Holes | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

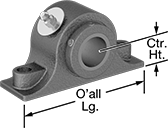

Mounted Tapered-Roller Bearings

Overall | Dynamic Load Cap., lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Ctr. Ht. | Lg. | Wd. | Radial | Thrust | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Cast Iron Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/2" | 6" | 2 3/4" | 3,800 | 2,000 | 4,400 | Steel | Sealed | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 7/8" | 7 3/8" | 3" | 6,100 | 2,550 | 3,800 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 1/8" | 7 7/8" | 3 3/8" | 7,850 | 2,550 | 3,300 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 2 1/8" | 7 7/8" | 3 3/8" | 7,850 | 2,550 | 3,300 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 8 7/8" | 3 1/2" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 8 7/8" | 3 1/2" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2 3/4" | 10 1/2" | 4" | 11,600 | 3,450 | 2,400 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2 3/4" | 10 1/2" | 4" | 11,600 | 3,450 | 2,400 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3 1/8" | 12" | 4 1/2" | 12,300 | 5,150 | 2,000 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3 1/8" | 12" | 4 1/2" | 12,300 | 5,150 | 2,000 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3 3/4" | 14" | 5" | 19,600 | 5,150 | 1,600 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 4 1/4" | 15 1/4" | 6 1/4" | 26,900 | 6,900 | 1,500 | Steel | Sealed | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 1 7/8" | 7 3/8" | 3" | 6,100 | 2,550 | 3,800 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 2 1/8" | 7 7/8" | 3 3/8" | 7,850 | 2,550 | 3,300 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 2 1/4" | 8 7/8" | 3 1/2" | 10,300 | 2,550 | 3,000 | Steel | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Precision Angular Contact Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Material | Dynamic Combined Load Cap., lbf | Max. Rotation Speed, rpm | Lubrication | Contact Angle | Min. | Max. | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 55 | 13 | 7 | Steel | 3,550 | 27,100 | Lubricated | 15° | 0 | 230 | 7006 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 62 | 14 | 7 | Steel | 4,500 | 23,800 | Lubricated | 15° | 0 | 230 | 7007 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 68 | 15 | 7 | Steel | 4,850 | 21,300 | Lubricated | 15° | 0 | 230 | 7008 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 75 | 16 | 7 | Steel | 5,750 | 19,200 | Lubricated | 15° | 0 | 230 | 7009 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 80 | 16 | 7 | Steel | 6,100 | 17,700 | Lubricated | 15° | 0 | 230 | 7010 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 90 | 18 | 7 | Steel | 8,050 | 15,900 | Lubricated | 15° | 0 | 230 | 7011 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 95 | 18 | 7 | Steel | 8,300 | 14,900 | Lubricated | 15° | 0 | 230 | 7012 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | 100 | 18 | 7 | Steel | 8,750 | 14,000 | Lubricated | 15° | 0 | 230 | 7013 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

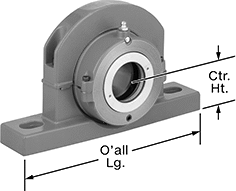

Easy-Access Mounted Cylindrical-Roller Bearings

Bearings | Replacement Bearings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Dynamic Load Cap., lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia. | Ctr. Ht. | Lg. | Wd. | Radial | Thrust | Max. Rotation Speed, rpm | Bearing Material | Bearing Seal Type | Shaft Mount Type | Misalignment Capability | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Cast Iron Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial and Thrust Loads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2 3/4" | 10 5/8" | 2 3/8" | 18,290 | 280 | 5,420 | Steel | Sealed | Clamp On | 3° | 0000000 | 000000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/16" | 3 5/32" | 11" | 2 3/4" | 20,250 | 350 | 4,460 | Steel | Sealed | Clamp On | 3° | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/16" | 3 5/32" | 11" | 2 3/4" | 20,250 | 350 | 4,460 | Steel | Sealed | Clamp On | 3° | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/16" | 3 3/4" | 13" | 3" | 29,840 | 430 | 3,750 | Steel | Sealed | Clamp On | 3° | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||