Filter by

System of Measurement

Shaft Diameter

For Use With

Maximum Rotation Speed

Case Material

Hardness Rating

Loaded Type

Maximum Pressure

For Sealing

Maximum Temperature

For Shaft Motion

Spring Material

Minimum Temperature

RoHS

Export Control Classification Number (ECCN)

DFARS Specialty Metals

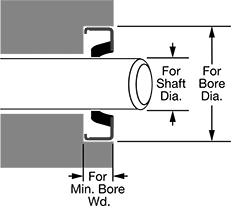

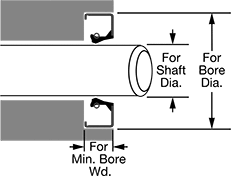

Bore-Sealing Spring-Loaded Rotary Shaft Seals with Wiper Lip

|  |  | |

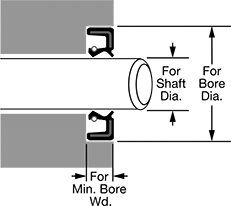

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Core and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 7.000 | 35.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 38.000 | 7.000 | 38.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 47.000 | 7.000 | 47.000 | 7.300 | 10,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 8.000 | 52.000 | 8.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

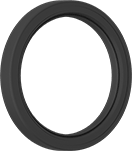

Rotary Shaft Seals for Grease

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 32.000 | 4.000 | 32.000 | 4.300 | 7,600 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 4.000 | 35.000 | 4.300 | 7,600 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

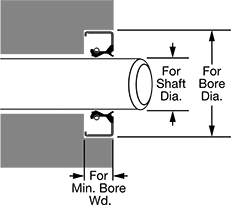

Spring-Loaded Rotary Shaft Seals with Wiper Lip

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 47.000 | 7.000 | 47.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 7.000 | 52.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring-Loaded Rotary Shaft Seals

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Finish | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 7.000 | 35.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 38.000 | 7.000 | 38.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 8.000 | 52.000 | 8.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mechanical Pump Shaft Seals with Extended Spring

|

Seal with Retainer and Straight Spring |

Seal, mm | Seat, mm | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | Mfr./Brand Equiv. | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Spring Shape | Includes | Max. Pressure, psi | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Case and 304 Stainless Steel Spring with Buna-N Diaphragm and Buna-N Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 25.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Case and 304 Stainless Steel Spring with EPDM Diaphragm and EPDM Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 25.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||