Filter by

System of Measurement

Seal OD

For Cylinder Type

Material

For Use With

For Shaft Motion

Groove Diameter

Loaded Type

Cylinder Seal Type

O-Ring Material

Maximum Speed

Filler Material

Maximum Temperature

Maximum Pressure

REACH

Export Control Classification Number (ECCN)

DFARS Specialty Metals

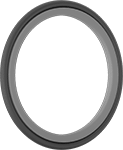

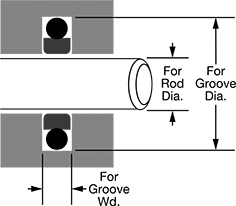

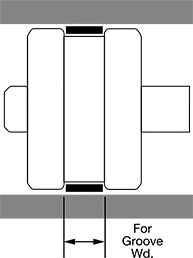

High-Speed Rod Seals

|  | |

Profile |

For Groove | O-Ring | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | Dia. | Wd. | Max. Speed, ft/sec | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Hardness | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze-Filled PTFE with Buna-N O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.171" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.421" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.671" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1.796" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.921" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.171" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2.296" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.421" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 2.546" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.671" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.921" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

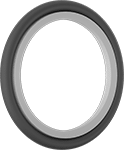

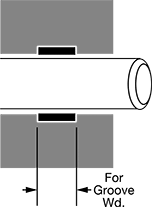

High-Speed Hydraulic Cylinder Buffering Seals

|  |  | |

Side 1 | Side 2 | Profile |

For Groove | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | Dia. | Wd. | Max. Speed, ft/sec | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | O-Ring Hardness | O-Ring Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze-Filled PTFE with Buna-N O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.912" | 0.126" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.287" | 0.126" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.537" | 0.126" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.671" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.787" | 0.126" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.171" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.421" | 0.165" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3.094" | 0.248" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.594" | 0.248" | 12 | 5,000 | -30 to 230 | Durometer 60D (Extra Hard) | Brown | Durometer 70A (Hard) | Black | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

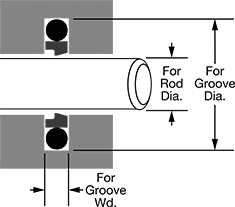

Wear Ring Stock

|  |  | |

Profile View | Piston Installation | Rod Installation |

Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Sealing | For Groove Wd. | Roll Lg., ft. | Wd. | Thk. | Max. Speed, ft/sec | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze-Filled PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.250" | 5 | 0.250" | 0.063" | 50 | -400 to 550 | Durometer 65D (Extra Hard) | Brown | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.250" | 5 | 0.250" | 0.094" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.250" | 5 | 0.250" | 0.125" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.375" | 5 | 0.375" | 0.094" | 50 | -400 to 550 | Durometer 65D (Extra Hard) | Brown | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.375" | 5 | 0.375" | 0.125" | 50 | -400 to 550 | Durometer 65D (Extra Hard) | Brown | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.500" | 5 | 0.500" | 0.094" | 50 | -400 to 550 | Durometer 65D (Extra Hard) | Brown | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.500" | 5 | 0.500" | 0.125" | 50 | -400 to 550 | Durometer 65D (Extra Hard) | Brown | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.750" | 5 | 0.750" | 0.063" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 0.750" | 5 | 0.750" | 0.125" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 1.000" | 5 | 1.000" | 0.063" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 1.000" | 5 | 1.000" | 0.094" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pistons, Rods | 1.000" | 5 | 1.000" | 0.125" | 50 | -400 to 550 | Durometer 66D (Extra Hard) | Brown | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

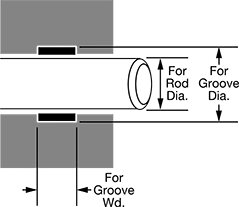

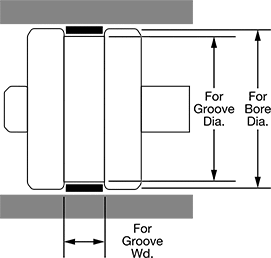

High-Speed Wear Rings

| |

Profile |

|  |

Rod Installation | Piston Installation |

For Rod Sealing | For Piston Sealing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | For Groove Dia. | For Bore Dia. | For Groove Dia. | Gap Size | Max. Speed, ft/sec | Temp. Range, ° F | Hardness | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze-Filled PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.250" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.000" | 2" | 1.750" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2.125" | 2 1/8" | 1.875" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 2.375" | 2 3/8" | 2.125" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.500" | 2 1/2" | 2.250" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.750" | 2 3/4" | 2.500" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3.000" | 3" | 2.750" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.250" | 3 1/4" | 3.000" | 0.175" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 4.000" | 4" | 3.750" | 0.175" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.375" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.000" | 2" | 1.750" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.500" | 2 1/2" | 2.250" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3.000" | 3" | 2.750" | 0.140" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.250" | 3 1/4" | 3.000" | 0.175" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3.500" | 3 1/2" | 3.250" | 0.175" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 4.000" | 4" | 3.750" | 0.175" | 13 | -200 to 575 | Durometer 65D (Extra Hard) | Brown | ASTM D4745, SAE AMS3678 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rod Glands with Seals

For Rod Dia. | Rod Gland Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Miller HV3 Series | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyurethane Rubber Rod Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | Bronze | -10 to 165 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Bronze | -10 to 165 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Bronze | -10 to 165 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Bronze | -10 to 165 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Parker 2H, 2L, 3L, H, L, and VH Series | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyurethane Rubber Rod Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Bronze | -10 to 165 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

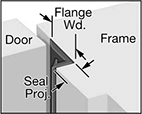

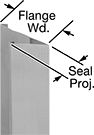

Adhesive-Back Frame-Mount Weatherstripping

Seal Material | For Max. Door Gap | Seal Projection | Flange Wd. | Fire Safety Rating | Mounting Fasteners Included | Adhesive Type | Lg., ft. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

V-Strip Weatherstripping Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bronze | 3/16" | 3/16" | 1" | UL 10B, UL 10C: 1 1/2 hr. for Wood Fire Doors, 3 hr. for Metal Fire Doors | No | Acrylic | 7 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||