Compare wire vs. cable and choose the right option based on gauge, number of conductors, insulation, and current rating.

About Wire and Cable

More

Servomotor Continuous-Flex Cable

- Use For: Automation, Continuous Motion, Interference Shielding, Motors

- Continuous Flex

- Temperature Range: -40° to 175° F

- Insulation:

Outer: Polyurethane Rubber

Inner: Polypropylene Plastic

Connect servocontrollers and servomotors in automated equipment and on assembly lines. This cable withstands continuous motion without degrading data or signal transmission. The polyurethane rubber insulation resists abrasion and oil. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Cable with power wires sends electricity to run a servomotor.

Cable with signal wires is also known as feedback cable. It sends and receives signals between a servomotor and a PLC.

Cable with power and signal wires sends data such as positioning information from a servomotor to a controller. It has four power wires and two pairs of signal wires.

Shielded cable has a layer of braid that blocks signal interference from nearby equipment and devices. Double shielded cable has a layer of braid and foil shielding for better protection against signal interference than braid alone. Use it in environments with high signal distortion, such as near transformers, generators, and heavy duty motors.

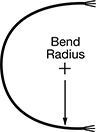

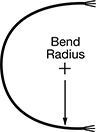

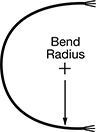

Bend radius is the point to which the cable will bend without being damaged. It is measured from the center of the bend to the edge of the cable. The smaller the measurement, the tighter the bend.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Wires | Wire Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | Length, ft. | 1-49 | 50-Up | |

Double Shielded—1,000V AC | ||||||||||||

| 4 | 14 | 14/4 | 15 A @ 86° F | 0.42" | 3.15" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 4 | 12 | 12/4 | 20 A @ 86° F | 0.47" | 3.53" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 0000 | |

| 4 | 10 | 10/4 | 30 A @ 86° F | 0.57" | 4.28" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| No. of Wires | Wire Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | 5 ft. | 10 ft. | 20 ft. | 30 ft. | 50 ft. | |

Shielded—30V AC/45V DC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 26 | 26/8 | 0.7 A @ 86° F | 0.25" | 2.17" | Green | Black, Blue, Brown, Green, Orange, Purple, Red, Yellow | UL Recognized Component, UL 2556 VW-1 | 0000000 | |||||

| 8 | 24 | 24/8 | 1.4 A @ 86° F | 0.29" | 1.87" | Green | Blue, Brown, Gray, Green, Pink, Red, White, Yellow | UL Recognized Component, UL 2556 VW-1 | 0000000 | |||||

Power Wire | Signal Wire | Per Ft. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Ga. | Cable AWG | No. of | Ga. | Cable AWG | No. of | Ga. | Cable AWG | Current | OD | Bend Radius | Outer Insulation Color | Inner Insulation Color | Specifications Met | Length, ft. | 1-49 | 50-Up | |

Double Shielded—1,000V AC | ||||||||||||||||||

| 4 | 14 | 14/4 | 4 | 18 | 18/4 | __ | __ | __ | 15 A @ 86° F | 0.57" | 4.28" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 000000 | 000000 | |

| 4 | 12 | 12/4 | 2 | 18 | 18/2 | 2 | 16 | 16/2 | 20 A @ 86° F | 0.64" | 4.8" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

| 4 | 10 | 10/4 | 2 | 18 | 18/2 | 2 | 16 | 16/2 | 30 A @ 86° F | 0.71" | 5.33" | Orange | Black, Green/Yellow | UL Recognized Component, CSA Certified, UL 2556 VW-1 | 0000000 | 00000 | 00000 | |

Outdoor Wire

The EPDM insulation on this wire won’t become brittle or crack from sunlight, humidity, rain, temperature changes, abrasion from dirt and debris, and other rough outdoor conditions. It meets Mine Safety and Health Administration (MSHA) standards for material quality.

DLO wire carries higher voltages than SC wire, making it the better choice for heavy duty applications. Use it to run power to motors, cranes, and other equipment in shipyards, mines, and oil- and gas-drilling rigs. Also known as diesel locomotive cable, this wire was originally designed to wire trains. An outer layer of chlorinated polyethylene plastic (CPE) gives it increased resistance to chemicals, heat, and flames. It’s also rated RHW-2, so it can be used underground and in wet locations.

All are flame rated, so they meets requirements for preventing the spread of flames based on a timed test. FT4 wire is mounted to a vertical tray during testing.

- Use for outdoors, buildings, power supply

- Flexible

- Maximum Temperature: 190° F

- Insulation:

Outer: Chlorinated Polyethylene Plastic

Inner: EPDM Rubber

| Wire Ga. | Current | OD | Outer Insulation Color | Industry Designation | Specifications Met | Certification | 10 ft. Lg. | 25 ft. Lg. | 50 ft. Lg. | 100 ft. Lg. | |

Stranded Wire | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | Not Rated | 0.21" | Black | DLO, RHW-2 | UL Listed, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 10 | Not Rated | 0.27" | Black | DLO, RHW-2 | UL Listed, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 8 | 55 A @ 86° F | 0.33" | Black | DLO, RHW-2 | UL Listed, CSA Certified, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 6 | 75 A @ 86° F | 0.37" | Black | DLO, RHW-2 | UL Listed, CSA Certified, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 4 | 95 A @ 86° F | 0.44" | Black | DLO, RHW-2 | UL Listed, CSA Certified, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 2 | 130 A @ 86° F | 0.5" | Black | DLO, RHW-2 | UL Listed, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 1/0 | 170 A @ 86° F | 0.65" | Black | DLO, RHW-2 | UL Listed, CSA Certified, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 2/0 | 195 A @ 86° F | 0.69" | Black | DLO, RHW-2 | UL Listed, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||

| 4/0 | 260 A @ 86° F | 0.82" | Black | DLO, RHW-2 | UL Listed, UL 2556 FT4 | MSHA Accepted | 0000000 | ||||