Filter by

System of Measurement

Thread Size

Fastener Head Type

Material

Thread Spacing

Drive Style

Finish

Thread Type

Thread Direction

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Hardness

Locking Type

Nose Material

Performance

Body Material

Steel Cup-Tip Set Screws

|

Lg. | Drive Size | Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8-36 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 91375A203 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 91375A204 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 91375A205 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 91375A206 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 50 | 91375A207 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 91375A208 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 91375A228 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Cup-Tip Set Screws

Steel Cone-Tip Set Screws

Lg. | Cone Point Angle | Drive Size | Hardness | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8-36 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 90° | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 92695A739 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 90° | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 92695A741 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 90° | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 92695A742 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 90° | 5/64" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 92695A744 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

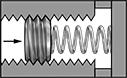

Steel Hollow-Tip Set Screws

|

Screw Used to Adjust Spring Tension |

|

Thread Size | Lg. | Drive Size | Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 7/64" | 5/64" | Rockwell C45 | 10 | 91301A238 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

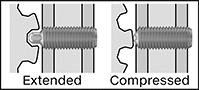

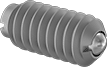

Ball-Nose Spring Plungers

|  |

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

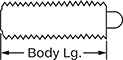

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

440C Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | 18-8 Stainless Steel | 0.34" | Spring Plunger Driver | Slotted | 3408A92 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | Black-Oxide Steel | 0.34" | Spring Plunger Driver | Slotted | 3408A69 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | 316 Stainless Steel | 0.34" | Spring Plunger Driver | Slotted | 8686A15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | Brass | 0.34" | Spring Plunger Driver | Slotted | 8687A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | 18-8 Stainless Steel | 0.34" | Spring Plunger Driver | Slotted | 34085A38 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | Steel | 0.34" | Spring Plunger Driver | Slotted | 84805A55 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Nose Spring Plungers

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 0.5 | 1.5 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 3126A81 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 1.5 | 4.8 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 3126A82 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.093" | 0.07" | 1 | 3.3 | Black-Oxide Steel | 0.44" | Spring Plunger Driver | Slotted | 3126A221 | 0000 | 3382A13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84985A45 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 0.5 | 1.5 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 8490A89 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 1.5 | 4.8 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84985A47 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 1.5 | 4.8 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 8490A81 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.093" | 0.07" | 1 | 3.3 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84985A12 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84765A17 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 0.5 | 1.5 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 8499A31 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 1.5 | 4.8 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84765A81 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.052" | 0.07" | 1.5 | 4.8 | Zinc-Plated Steel | 0.44" | Spring Plunger Driver | Slotted | 8499A32 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.093" | 0.07" | 1 | 3.3 | 18-8 Stainless Steel | 0.44" | Spring Plunger Driver | Slotted | 84765A321 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.093" | 0.07" | 1 | 3.3 | Black-Oxide Steel | 0.44" | Spring Plunger Driver | Slotted | 8499A821 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||