Filter by

Material

Application

Weight Capacity

Thickness

Straight-Link Chain Trade Size

Pin Material

Attachment Type

Color

Specifications Met

For Use With

DFARS Specialty Metals

Export Control Classification Number (ECCN)

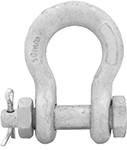

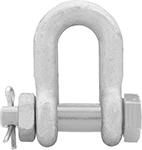

Anchor Shackles for Lifting

|

Screw Pin |

|

Safety Cotter Pin |

|

Flush Hammer-Set-Dowel Pin |

Your go-to choice for connecting hooks, slings, and other rigging and lifting equipment. The rounded body on these shackles supports vertical or side loads without fatiguing or warping the shape. They meet ASME specifications for rigging and lifting, so they can hoist everything from steel beams to bulldozers. Look for the manufacturer's stamp to confirm the size and weight capacity. Also known as bow shackles.

Note: Capacities listed are for vertical lifting only. As the lift angle changes from vertical, the amount of weight the shackle can lift is significantly reduced.

Screw Pin—The most common shackle pin type. Although the pin easily connects and disconnects, it can come unscrewed or wear down over time, so it's best for temporary use.

Safety Cotter Pin—Both a threaded nut and cotter pin hold these shackles in place. Also known as bolt-type shackles, the pin won’t slide out with movement. This means you can use these shackles with vibrating equipment and for long-term rigging setups.

Flush Hammer-Set-Dowel Pin—Hammer in two dowel pins to hold the pin in place. These shackles stay put even under heavy, shifting loads and in long-term rigging setups. They also won't snag on clothing or other nearby material.

Black-Oxide Steel—The dark finish on these shackles resists occasional moisture.

Galvanized Steel—A thick coating protects these shackles in wet and outdoor environments better than black-oxide steel. However, they corrode when exposed to salt water and chemicals.

High-Strength Galvanized Alloy Steel—Stronger than galvanized steel with corrosion resistance in wet and outdoor environments.

High-Strength Powder-Coated Alloy Steel—The powder-coating won't chip off as easily as paint. These shackles combine the strength of alloy steel with corrosion resistance in wet and outdoor environments.

Super-Corrosion-Resistant 316 Stainless Steel—Our most corrosion-resistant shackles stand up to moisture, salt water, and chemicals.

Thk. | Opening Wd. | Pin Dia. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 23/32" | 1/2" | 1 11/16" | 1 5/16" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 8494T15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 23/32" | 1 3/16" | 3,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3558T48 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Galvanized Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 23/32" | 1/2" | 1 11/16" | 1 3/16" | 5,200 | ASME B30.26 | 3663T53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 25/32" | 1 1/16" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3583T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Cotter Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 23/32" | 1/2" | 1 11/16" | 1 5/16" | 3,000 | ASME B30.26, Fed. Spec. RR-C-271 | 8494T29 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 23/32" | 1 3/16" | 3,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3555T49 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 25/32" | 1 1/16" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 3860T24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flush Hammer-Set-Dowel Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Powder-Coated Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 7/8" | 9/16" | 1 13/16" | 1 3/32" | 7,100 | ASME B30.26 | 3812T22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

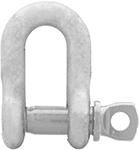

D-Type Shackles for Lifting

|

Screw Pin |

|

Safety Cotter Pin |

The best choice for lifting with chain. The bow and pin are equally wide to keep chain links from sliding or moving and support heavier vertical loads than anchor shackles. However, they're rated for vertical lifting only, as side loading might deform the bow. All meet ASME specifications for use with rigging and lifting equipment. Look for the manufacturer's stamp to confirm the size and weight capacity. Also known as chain shackles.

Note: Capacities listed are for vertical lifting only. As the lift angle changes from vertical, the amount of weight the shackle can lift is significantly reduced.

Screw Pin—The most common shackle pin type. Although the pin easily connects and disconnects, it can come unscrewed or wear down over time, so it's best for temporary use.

Safety Cotter Pin—Both a threaded nut and cotter pin hold these shackles in place. Also known as bolt-type shackles, the pin won’t slide out with movement. This means you can use these shackles with vibrating equipment and for long-term rigging setups.

Galvanized Steel—A thick coating protects these shackles in wet and outdoor environments better than black-oxide steel. However, they corrode when exposed to salt water and chemicals.

Super-Corrosion-Resistant 316 Stainless Steel—Our most corrosion-resistant shackles stand up to moisture, salt water, and chemicals.

Thk. | Opening Wd. | Pin Dia. | Inside Lg. | Inside Wd. | Wt. Cap., lb. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 1/2" | 3/4" | 3,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3560T47 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 7/16" | 3/4" | 2,000 | ASME B30.26, Fed. Spec. RR-C-271 | 35895T119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Safety Cotter Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3/4" | 1/2" | 1 1/2" | 3/4" | 3,300 | ASME B30.26, Fed. Spec. RR-C-271 | 3556T29 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||