About Composites

More

Selecting Compatible Lead Screws and Nuts

More

About Shafts

More

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Stainless steel shafts are more corrosion resistant than steel shafts but more difficult to machine. 303 stainless steel shafts have good corrosion resistance and are easier to machine than other types of stainless steel.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Metric—1566 Carbon Steel | |||||||

|---|---|---|---|---|---|---|---|

30mm Dia. (Tolerance: -0.102mm to 0mm) | |||||||

| 200mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 000000 |

| 400mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 500mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,000mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,200mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 00000 |

| 1,500mm | -0.795mm to 0.795mm | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C25 | 0000000 | 000000 |

Metric—303 Stainless Steel | |||||||

30mm Dia. (Tolerance: -0.01mm to 0mm) | |||||||

| 100mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 200mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 00000 |

| 400mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 600mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 800mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

| 1,000mm | -0.25mm to 0.25mm | 0.18 mm per 300 mm | Chamfered | Medium | Rockwell B83 | 0000000 | 000000 |

Linear Motion Shafts

Smooth, hard, and wear resistant, these shafts work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. Carbon steel shafts are good for general purpose use. Alloy steel shafts are stronger and more wear resistant than carbon steel.

Stainless steel shafts are more corrosion resistant than steel shafts; however, they’re not as hard as steel shafts and can be more difficult to machine. 420 and 440C stainless steel shafts have good corrosion resistance and are harder than 17-4 PH stainless steel shafts, so they better resist wear.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

30 mm Dia. (Tolerance: -0.013 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 200 | -0.5 to 0.5 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 00000000 | 000000 |

| 500 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 00000 |

| 1,000 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,200 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,500 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 2,000 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 2,500 | -2 to 2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

30 mm Dia. (Tolerance: -0.01 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 750 | -1 to 1 | 0.03 mm per 300 mm | 8 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

30 mm Dia. (Tolerance: -0.02 mm to -0.007 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 100 | -0.5 to 0.5 | 0.050 mm per 300 mm | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 300 | -0.5 to 0.5 | 0.050 mm per 300 mm | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 00000 |

| 400 | -0.5 to 0.5 | 0.050 mm per 300 mm | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 00000 |

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

30 mm Dia. (Tolerance: -0.013 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 500 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 0000000 |

| 600 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 000000 |

| 800 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 000000 |

| 1,000 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 000000 |

| 1,200 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 000000 |

| 1,500 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 0000000 | 000000 |

Tapped Linear Motion Shafts

Internal threads allow you to mount these shafts onto threaded studs and fasteners, no shaft supports needed. These shafts work with linear bearings to reduce friction in manual and automated systems because they're smooth, hard, and wear resistant. You'll often see them in packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances.

The surface is hardened, so they stand up to repeated motion while keeping their center soft enough to absorb stress from shifting loads. Chamfered edges remove sharp corners at the end of these shafts, reducing damage to bearings, housings, and other components during installation.

Alloy steel shafts are stronger and resist wear better than stainless steel.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Size | Pitch | Lg. | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—52100 Alloy Steel | ||||||||||||

30mm Dia. (Tolerance: -0.02mm to -0.007mm) | ||||||||||||

| 400mm | -0.5mm to 0.5mm | M16 | 2 mm | 32mm | 0.050 mm per 300 mm | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 0000000 |

| 1,200mm | -0.8mm to 0.8mm | M16 | 2 mm | 32mm | 0.050 mm per 300 mm | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

Hollow Linear Motion Shafts

Lighter than solid shafts, hollow shafts reduce your total system weight and allow you to run various media such as electrical wiring, compressed air tubing, coolants, or lubricants through the center. These shafts are smooth, hard, and wear resistant, so they work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. The exterior of these shafts is turned, ground, and polished to tight diameter and straightness tolerances. The interior is unfinished.

These shafts are hardened on the surface, so they stand up to repeated motion. All have chamfered ends to remove sharp edges and reduce damage to bearings, housings, and other components during installation.

Carbon steel shafts are strong and good for general purpose use.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

| Lg. | Lg. Tolerance | Dia. Tolerance | ID Tolerance | Surface Smoothness, microinch | Hardness Rating | Hardness | Each | |

Metric—1055 Carbon Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

30mm Dia. (18.2mm ID) | ||||||||

| __ | __ | -0.021mm to 0mm | -0.91mm to 0.91mm | 12 | Very Hard | Rockwell C59 | 00000000 | 00 |

| 300mm | -0.5mm to 0.5mm | -0.021mm to 0mm | -0.91mm to 0.91mm | 12 | Very Hard | Rockwell C59 | 0000000 | 000000 |

| 500mm | -0.8mm to 0.8mm | -0.021mm to 0mm | -0.91mm to 0.91mm | 12 | Very Hard | Rockwell C59 | 0000000 | 000000 |

| 1,000mm | -0.8mm to 0.8mm | -0.021mm to 0mm | -0.91mm to 0.91mm | 12 | Very Hard | Rockwell C59 | 0000000 | 000000 |

| 1,500mm | -1.2mm to 1.2mm | -0.021mm to 0mm | -0.91mm to 0.91mm | 12 | Very Hard | Rockwell C59 | 0000000 | 000000 |

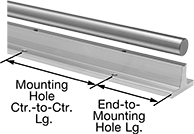

Support-Rail Shafts

These shafts include a support rail for a stable setup that eliminates bending and prevents linear bearings from rotating. Shafts have a smooth surface to reduce friction and wear on linear bearings—the lower the microinch value a shaft has, the smoother its finish and the less friction it will create. They are case-hardened to increase hardness and wear resistance on the surface of the shaft while allowing the center to remain soft for absorbing stresses caused by shifting loads. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances.

Two-piece shafts allow you to replace the shaft when it becomes worn.

Carbon steel shafts are stronger than aluminum shafts but not as corrosion resistant. These shafts balance high strength and good machinability, making them ideal for general purpose use.

Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Ctr. Ht. | O'all Wd. | End-to-Mount. Hole Lg. | Ctr.-to-Ctr. Lg. | Ctr.-to-Ctr. Wd. | Dia. | Mounting Fasteners Included | Surface Smoothness, microinch | Hardness Rating | Hardness | Each | |

Metric—1055 Carbon Steel | |||||||||||||

30mm Dia. (Tolerance: -0.013mm to 0mm) | |||||||||||||

| 1,200mm | -5mm to 0mm | 53mm | 74mm | 75mm | 150mm | 51mm | 9mm | No | 12 | Very Hard | Rockwell C60 | 00000000 | 0000000 |

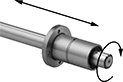

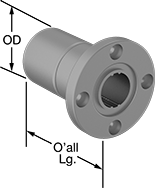

Ball Splines and Bearings

Create a compact linear and rotary motion system for applications requiring complex, fast movements, such as robotics. The grooves on the ball splines transmit rotary power as ball bearings move smoothly and precisely along their length, even at high speeds.

Ball splines are alloy steel for high strength and wear resistance. They're hardened on the outside for additional wear resistance while the center is soft enough to absorb stress from shifting loads.

Bearings have a retaining ring groove, so they can be positioned in your system with a retaining ring (not included). Bearings with a keyway include a machine key for attaching your load. Flanged bearings have a surface with mounting holes for attaching your load.

Spline | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Dia. Tolerance, mm | Lg., mm | Lg. Tolerance, mm | Lg., mm | No. of | Root Dia., mm | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—52100 Alloy Steel | |||||||||||||

Splined on Both Ends | |||||||||||||

| 30 | -0.02 to 0 | 300 | -0.05 to 0.05 | 300 | 4 | 26.8 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 0000000 |

| 30 | -0.02 to 0 | 1,000 | -0.08 to 0.08 | 1,000 | 4 | 26.8 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 000000 |

| 30 | -0.02 to 0 | 2,000 | -0.08 to 0.08 | 2,000 | 4 | 26.8 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 000000000 | 00000000 |

Material | Keyway | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | Includes | Dp., mm | Lg., mm | Wd., mm | Each | |

| 30 | 4 | 80 | 47 | Steel | Steel | 4,150 | 2,716 | Yes | Machine Key | 2.5 | 42 | 4 | 00000000 | 0000000 |

Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | Flange OD, mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | Number of Mounting Holes | Each | |

| 30 | 4 | 80 | 75 | 47 | Steel | Steel | 4,150 | 2,716 | Yes | 4 | 000000000 | 0000000 |

Low-Carbon Steel Rods and Discs

- Yield Strength: See table

- Hardness: See table

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: See table

- Fabrication: See table

- Specifications Met: See table

Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into low-strength fasteners, pins, and axles. You can surface harden this material for added wear resistance. All have been manufactured to meet ASTM standards for quality and performance.

Cold-worked rods and discs have a finished look and quality. The cold-working process gives the steel consistent strength, hardness, and dimensions throughout.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia., mm | Dia. Tolerance, mm | Yield Strength, psi | Fabrication | Hardness | Max. Hardness After Heat Treatment | Mechanical Finish | Specifications Met | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 4 ft. Lg. | 6 ft. Lg. | 8 ft. Lg. | |

| 30 | -0.01 to 0 | 50,000 | Cold Worked | Rockwell B70 (Medium) | Not Rated | Ground, Polished, Turned | ASTM A108 | 00000000 | |||||||

| 30 | -0.05 to 0 | 54,000 | Cold Worked | Rockwell B70 (Medium) | Not Rated | __ | ASTM A108 | 0000000 |

Tight-Tolerance Low-Carbon Steel Rods

- Yield Strength: Not Rated

- Hardness: Not Rated

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: See table

- Fabrication: Cold Drawn

- Specifications Met: ASTM A108

These rods are precision ground and held to a strict straightness tolerance, so they're ready for turning in a lathe. Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into low-strength fasteners, pins, and axles. For added wear resistance, this material can be surface hardened with heat treating. All have been manufactured to meet ASTM A108 standards for quality and performance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

High-Strength Easy-to-Machine 1144 Carbon Steel Rods

- Yield Strength: 100,000 psi

- Hardness:

Inch sizes: Rockwell C25 (Hard)

Metric sizes: Rockwell C19 (Medium) - Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Fabrication: Cold Drawn

- Specifications Met: ASTM A108, ASTM A311

Made with more carbon and manganese than other easy-to-machine carbon steels, 1144 carbon steel has a higher yield strength and hardness. Also known as Stressproof, these rods are stress-relieved to minimize warping during machining. Use them to fabricate parts that require stress resistance, such as gears, shafts, and bushings. For added wear resistance, these rods can be surface hardened with heat treating. All meet ASTM A108 and ASTM A311 standards for quality and performance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance Ultra-Machinable 12L14 Carbon Steel Rods

- Yield Strength: 65,000 psi

- Hardness: Rockwell B80 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C65

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

Ready for turning in a lathe, these rods are precision ground and held to a strict straightness tolerance. The lead additive acts as a lubricant, which allows 12L14 carbon steel to withstand very fast machining. It's used to fabricate a wide variety of machine parts, such as shaft couplings, studs, and pins. These rods meet ASTM A108 quality and performance standards. For added wear resistance, they can be surface hardened with heat treating.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Easy-to-Machine 1215 Carbon Steel Rods

- Yield Strength: 60,000 psi

- Hardness: Rockwell B85 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

A lead-free alternative to 12L14, 1215 carbon steel contains the same amount of sulfur and phosphorus for excellent machinability. It’s often used for shaft couplings, studs, and pins. For added wear resistance, you can harden its surface with heat treating. These rods meet ASTM A108 standards for manufacturing processes and performance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

High-Strength 1045 Carbon Steel Rods and Discs

Stronger than low-carbon steel with equally good machinability, 1045 carbon steel is widely used for bolts, studs, and shafts.

If you don't see the size you're looking for, please specify a length under additional rod lengths.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 60,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C60

- Fabrication: Cold Drawn

- Specifications Met: ASTM A108

Ready for turning in your lathe, these rods are precision ground and held to a strict straightness tolerance. Also known as chrome-moly steel, this versatile alloy steel is used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. It resists fracturing from repeated stress. For added wear resistance, you can surface harden these rods with heat treating. They are manufactured to ASTM A108 standards for performance and quality.

Note: Rods may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Easy-to-Machine High-Strength Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 130,000 psi

- Hardness: Rockwell C32 (Hard)

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

Often called ETD-150, this modified alloy steel is drawn at high temperatures for excellent strength and machinability. Also known as chrome-moly steel, 4140 alloy steel resists fracturing from repeated stress. It is used for a wide range of parts, such as gears, axles, and shafts. These rods have been hardened for added resistance to abrasion and impact. All have been manufactured to meet ASTM A108 standards for quality and performance.

Note: Rods may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Multipurpose 4140 Alloy Steel Rods and Discs

Also known as chrome-moly steel, this versatile alloy steel is used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. It resists fracturing from repeated stress. For added wear resistance, the surface can be hardened with heat treating. These rods and discs have been manufactured to meet ASTM standards for quality and performance.

Note: Rods and discs may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

Cold-worked steel rods and discs have a smooth, polished finish. They also have consistent mechanical properties and highly accurate dimensions.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 60,000 psi

- Hardness: Rockwell C10 (Medium)

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Not Rated

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

Tight-Tolerance Multipurpose Oil-Hardening O1 Tool Steel Rods

- Yield Strength: 50,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Rockwell C65

- Fabrication: Hot Rolled

- Specifications Met: ASTM A681

Ready for turning in a lathe, these rods are precision ground to a tight diameter tolerance. They’re also known as drill rod. Often used for dies, punches, and gauges, O1 tool steel is an oil-hardening material that resists wear and abrasion. It can also be surface hardened with heat treating for added wear resistance. These rods have been manufactured to meet ASTM A681 standards for performance and quality.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Multipurpose 304 Stainless Steel

From cookware to chemical-processing equipment, 304 stainless steel is a good all-around choice for a wide range of applications. It maintains its corrosion resistance in temperatures up to 1500° F.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance High-Strength 17-4 PH Stainless Steel

Each piece is precision ground to offer tighter tolerances than standard 17-4 PH stainless steel. With a higher chromium content than 15-5 PH stainless steel, this high-strength material offers better corrosion resistance. It's also known as 630 stainless steel. It maintains its corrosion resistance in temperatures up to 1100° F.

Rods are held to a strict diameter tolerance, so they’re ready for turning in your lathe.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 118,000 psi

- Hardness: See table

- Heat Treatment: Annealed (Softened)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C47

- Specifications Met: ASTM A564

Hardened Tight-Tolerance High-Strength 17-4 PH Stainless Steel

- Yield Strength: 170,000 psi

- Hardness: Rockwell C42 (Hard)

- Heat Treatment: Hardened

- Temper: H900

- Specifications Met: ASTM A564, SAE AMS5643

Hardened for improved strength and wear resistance, these rods are precision ground to a strict diameter tolerance. Use them for turning applications in your lathe. With a higher chromium content than 15-5 PH stainless steel, this high-strength 17-4 PH offers better corrosion resistance. It’s also known as 630 stainless steel. This material maintains its corrosion resistance in temperatures up to 1100° F.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Multipurpose 6061 Aluminum Rods and Discs

- Yield Strength: 35,000 psi

- Hardness:

Foot and inch sizes: Brinell 95 (Soft)

Metric sizes: Brinell 80 (Soft) - Temper: See table

- Fabrication: See table

- Specifications Met:

Cold Worked: ASTM B211

Extruded: ASTM B221

Cold Rolled: ASTM B209

The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

If you don't see the size you're looking for, please specify a length under additional rod lengths.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance Multipurpose 6061 Aluminum Rods and Discs

These rods and discs are precision ground to offer tighter tolerances than standard 6061 rods and discs. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Rods are held to a strict straightness tolerance, so they’re all set for turning in your lathe.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance High-Strength 7075 Aluminum Rods

- Yield Strength: 73,000 psi

- Hardness: Brinell 150 (Medium)

- Temper: T6

- Fabrication: Cold Worked

- Specifications Met: ASTM B211

Ready for turning in a lathe, these rods are precision ground and held to a strict straightness tolerance. Originally developed for aircraft frames, uses for 7075 aluminum now include keys, gears, and other high-stress parts. It is often used as a replacement for 2024 aluminum because it’s stronger and provides similar performance in all other aspects.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Fast-Travel Ball Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than ball screws with a single thread start. Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. To ensure compatibility, select components that have the same thread size and number of thread starts. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Carbon steel ball screws and nuts are case hardened, so they resist wear better than standard carbon steel. However, they are less corrosion resistant than black-oxide alloy steel screws and nuts.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

| Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Carbon Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | M12 | 50mm | 30mm | 1 | 10mm | M25 | Rockwell C56 | 1,000 | 0.02mm | 32° to 150° | 00000000 | 0000000 |

Multipurpose Flame-Retardant Garolite G-10/FR4 Rods

- Color: See Table

- Temperature Range: -100° F to 245° F

- Tensile Strength: 35,000-50,000 psi (Excellent)

- Impact Strength: 5.5-12 ft.-lbs./in. (Excellent)

- Hardness: Rockwell M115 (Extra Hard)

- For Use Outdoors: Yes

- Specifications Met: MIL-I-24768/27, UL 94 V-0

Made of a flame-retardant epoxy resin with fiberglass fabric reinforcement, these G-10/FR4 rods are a good all-around choice. They are strong, machinable, and electrically insulating. Garolite G-10/FR4 is also called epoxy-grade industrial laminate and phenolic.