Filter by

System of Measurement

Thread Size

Component

Nut Type

Material

Thread Direction

Flange Material

Travel Distance per Turn

Threading

Speed Ratio

Number of Thread Starts

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Hardness

Performance

REACH

RoHS

Tensile Strength

Thread Type

Flange Hardness

Flange Thickness

Maximum Temperature

Ultra-Precision Lead Screws and Nuts

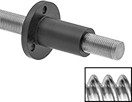

Lead Screws—Right-Hand Thread

Thread Size | Lg., ft. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-20 | 3 | Rounded Acme | 1:1 | 1 | 0.05" | ±0.0006"/1" | Brinell 160 | 90,000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-20 | 6 | Rounded Acme | 1:1 | 1 | 0.05" | ±0.0006"/1" | Brinell 160 | 90,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

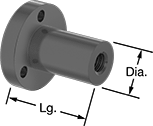

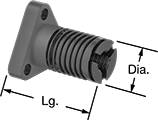

Flange Nuts—Right-Hand Thread

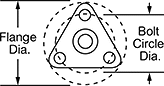

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

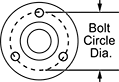

Style | Thread Size | Lg. | Dia. | Dia. | Thk. | Thread Type | Speed Ratio | Bolt Circle Dia. | No. of Thread Starts | Travel Distance per Turn | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3/8"-20 | 1" | 0.625" | 1 7/64" | 3/16" | Rounded Acme | 1:1 | 7/8" | 1 | 0.05" | Not Rated | 9,700 | 75 | 3 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal with Wear-Compensating Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/8"-20 | 1 29/32" | 0.703" | 1 1/2" | 3/16" | Rounded Acme | 1:1 | 1 1/8" | 1 | 0.05" | Not Rated | 9,700 | 10 | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||