Filter by

System of Measurement

Thread Size

Length

Component

Shape

Thread Type

Nut Type

End Type

Threading

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Thread Direction

Finish

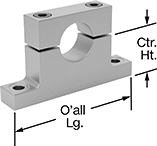

Easy-Access Base-Mount Linear Shaft Supports

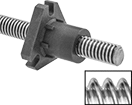

Metric Fast-Travel Ultra-Precision Lead Screws and Nuts

|  |  |  |

Style B | Style C | Style D |

Lead Screw—Right-Hand Thread

Thread Size | Lg., mm | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.5 mm | 50 | Metric Rounded Trapezoidal | 2:1 | 2 | 1 | ±0.089 mm/300 mm | Brinell 160 | 90,000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.5 mm | 100 | Metric Rounded Trapezoidal | 2:1 | 2 | 1 | ±0.089 mm/300 mm | Brinell 160 | 90,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 145 | Metric Rounded Trapezoidal | 2:1 | 2 | 0.75 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 145 | Metric Rounded Trapezoidal | 4:1 | 4 | 1.5 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 145 | Metric Rounded Trapezoidal | 8:1 | 8 | 3 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

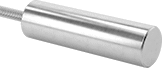

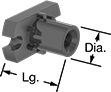

Lead Screw with One Machinable End—Right-Hand Thread

End, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg., mm | Thread Type | Dia. | Lg. | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 7 | 25 | 2:1 | 2 | 0.75 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 7 | 25 | 4:1 | 4 | 1.5 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 7 | 25 | 8:1 | 8 | 3 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead Screw with One Coupling End—Right-Hand Thread

End, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg., mm | Thread Type | Dia. | Lg. | For Shaft Dia. | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 2:1 | 2 | 0.75 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 4:1 | 4 | 1.5 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 8:1 | 8 | 3 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

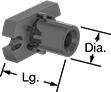

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Hex Wd. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M2 × 0.5 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 2:1 | 2 | 1 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 10 | -40 to 185 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 2:1 | 2 | 0.75 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 4:1 | 4 | 1.5 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 8:1 | 8 | 3 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

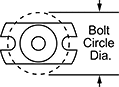

Flange Nuts—Right-Hand Thread

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Dia. | Wd. | Ht. | Thk. | Thread Type | Speed Ratio | Bolt Circle Dia. | No. of Thread Starts | Travel Distance per Turn, mm | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.5 mm | 1/2" | 0.297" | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 2:1 | 39/64" | 2 | 1 | Not Rated | 8,000 | 10 | 2 | -40 to 185 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 2:1 | 11/32" | 2 | 0.75 | Durometer 83D | Not Rated | 2 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 4:1 | 11/32" | 4 | 1.5 | Durometer 83D | Not Rated | 2 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 8:1 | 11/32" | 8 | 3 | Durometer 83D | Not Rated | 2 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK with Wear-Compensating Internal O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 2:1 | 11/32" | 2 | 0.75 | Durometer 83D | Not Rated | 1 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 4:1 | 11/32" | 4 | 1.5 | Durometer 83D | Not Rated | 1 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M2 × 0.4 mm | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 8:1 | 11/32" | 8 | 3 | Durometer 83D | Not Rated | 1 | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric Ultra-Precision Lead Screws and Nuts

Lead Screw—Right-Hand Thread

Thread Size | Lg., mm | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.5 mm | 50 | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | ±0.089 mm/300 mm | Brinell 160 | 90,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.5 mm | 100 | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | ±0.089 mm/300 mm | Brinell 160 | 90,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 145 | Metric Rounded Trapezoidal | 1:1 | 1 | 0.375 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead Screw with One Machinable End—Right-Hand Thread

End, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg., mm | Thread Type | Dia. | Lg. | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 7 | 25 | 1:1 | 1 | 0.375 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead Screw with One Coupling End—Right-Hand Thread

End, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg., mm | Thread Type | Dia. | Lg. | For Shaft Dia. | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 150 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 1:1 | 1 | 0.375 | ±0.15 mm/300 mm | Rockwell C35 | 145,000 | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Hex Wd. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M2 × 0.5 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 10 | -40 to 185 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 0.375 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange Nuts—Right-Hand Thread

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Dia. | Wd. | Ht. | Thk. | Thread Type | Speed Ratio | Bolt Circle Dia. | No. of Thread Starts | Travel Distance per Turn, mm | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.5 mm | 1/2" | 0.297" | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 1:1 | 39/64" | 1 | 0.5 | Not Rated | 8,000 | 10 | 2 | -40 to 185 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 1:1 | 11/32" | 1 | 0.375 | Durometer 83D | Not Rated | 2 | 2 | — | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK with Wear-Compensating Internal O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 1:1 | 11/32" | 1 | 0.375 | Durometer 83D | Not Rated | 1 | 2 | — | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

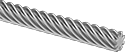

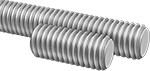

Threaded Rods

|

Stainless Steel

Lg. | Tensile Strength, psi | Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 70,000 | Not Rated | DIN 976 | 10 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 70,000 | Not Rated | DIN 976 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 70,000 | Not Rated | DIN 976 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 70,000 | Not Rated | DIN 976 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 70,000 | Not Rated | DIN 976 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 mm | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 m | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 m | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 70,000 | Not Rated | DIN 976 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 70,000 | Not Rated | DIN 976 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 mm | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 m | 70,000 | Not Rated | DIN 976 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass

Lg., m | Tensile Strength, psi | Hardness | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50,000 | Rockwell B55 | DIN 976 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||