Filter by

For Use On

Export Control Classification Number (ECCN)

DFARS Specialty Metals

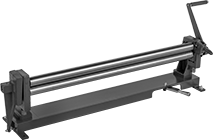

Slip Rollers

Roller | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending Wd. | For Max. Steel Thk. | Min. Bending Radius | For Wire Dia. | Ht. | Wd. | Dp. | Material | Dia. | No. of | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" | 1/2" | 1/16", 1/8" | 8" | 17" | 12" | Steel | 1" | 3 | Cast Iron | No | 4 | 3/8" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 38" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 51" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 1/64" | 1" | 3/16", 1/4", 5/16" | 19" | 57" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

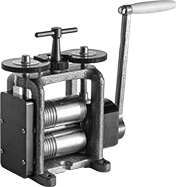

Benchtop Rolling Mills

Manual

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

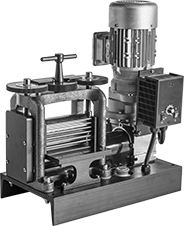

Electric

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Gear Speed Ratio | Ht. | Wd. | Dp. | Dia. | No. of | Material | Frame Material | Power, hp | Max. Rotation Speed, rpm | Current, amp | Voltage, V AC | Cord Lg., ft. | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | 3/16" | 100:1 | 19" | 22" | 15" | 2 1/2" | 2 | Steel | Cast Iron | 1/2 | 13 | 1.7 | 120 | 5 | No | 4 | 1/2" | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

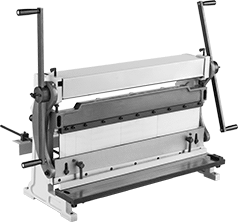

Shears/Benders/Curvers

Max. Bending | For Max. Thk. | Roller | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Angle | Aluminum | Brass | Copper | Stainless Steel | Steel | Min. Bending Radius | Cut Lg. | Ht. | Wd. | Dp. | Dia. | No. of | Blade Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 90° | 1/32" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 12" | 15" | 14" | 11" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 30" | 23" | 32 1/2" | 14 1/2" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 7/8" | 40" | 23" | 42 1/2" | 14 1/2" | 1 5/8" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||