Filter by

System of Measurement

Thickness

Shape

Form

Backing Type

REACH

Temper Rating

Sold As

Performance

Magnetic Properties

End Shape

Export Control Classification Number (ECCN)

Hardness

Minimum Hardness

Specifications Met

Shim Stock

|

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk., mm | Thk. Tolerance, mm | Temper Rating | Type | Form | Specs. Met | Form | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 1,250 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0025 to 0.0025 | Full Hard | Material Certificate | Paper | ASTM A666 | Roll | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 2,500 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0025 to 0.0025 | Full Hard | Material Certificate | Paper | ASTM A109, Fed. Spec. QQ-S-698 | Roll | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

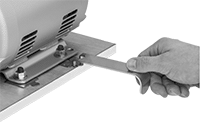

Slotted Shims

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot, mm | Each | Package | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | Each | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm Lg. × 50 mm Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0035 to 0.0035 | M15 | 15.9 | 25.4 | Rockwell C40 | Labeled | Tab | 00000000 | 00000 | 10 | 00000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75 mm Lg. × 75 mm Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0035 to 0.0035 | M22 | 22.3 | 38.1 | Rockwell C40 | Labeled | Tab | 00000000 | 0000 | 10 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100 mm Lg. × 100 mm Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0035 to 0.0035 | M30 | 31.8 | 50.8 | Rockwell C40 | Labeled | Tab | 00000000 | 0000 | 10 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125 mm Lg. × 125 mm Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.05 | -0.0035 to 0.0035 | M40 | 41.3 | 84.1 | Rockwell C40 | Labeled | Tab | 00000000 | 00000 | 10 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||