Sights for Quick-Clamp Sanitary Tube Fittings

Quick-Clamp Fitting, And Tube

Fitting (All Sold Separately)

Monitor food, brewery, chemical, pharmaceutical, and biotech processing lines with these sights that attach to quick-clamp fittings for fast installation and easy removal for cleaning. All have a one-piece design, so there are no crevices where bacteria can grow. A

304 stainless steel sights have a ring that's embedded around their shatter-resistant plastic window. This design protects the sights from chipping or cracking while under the stress of the quick-clamp fitting. All withstand harsh cleaners and sanitizers for clean-in-place (CIP) and steam-in-place (SIP) applications. They do not contain Bisphenol A (BPA), Bisphenol B (BPB), or BPA derivatives (BPX), which are chemicals that can contaminate your process lines. All meet ASME BPE design standards for bioprocessing equipment that ensure purity and safety.

For superior strength and reliability, choose 2205 stainless steel sights. All have a glass window that’s melted around a high-strength ring, so they won’t shatter, leak, or lose their shape under high pressure, heat, chemicals, or impact. They withstand harsh cleaners and sanitizers for clean-in-place (CIP) and steam-in-place (SIP) applications. USP Class VI and TUV Rheinland Certified, these sights meet safety standards in the U.S. and Europe. They also meet DIN standards for glass materials used in sights, ASTM standards for materials used in boilers and pressure vessels, and ASME BPE design standards for bioprocessing equipment that ensure purity and safety.

Temp. Range, °F | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Flange OD | Window Dia. | Max. Pressure | Min. | Max. | For Use With | Features | Specifications Met | Each | |

304 Stainless Steel Ring with Plastic Window | ||||||||||

| 1" | 1.98" | 1 1/4" | 150 psi @ 70° F | Not Rated | 200° | Water, Acetic Acid, Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | One-Piece Construction | ASME BPE | 0000000 | 0000000 |

| 2" | 2.52" | 1 3/4" | 150 psi @ 70° F | Not Rated | 200° | Water, Acetic Acid, Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | One-Piece Construction | ASME BPE | 0000000 | 000000 |

| 4" | 4.68" | 3 1/4" | 30 psi @ 70° F | Not Rated | 200° | Water, Acetic Acid, Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | One-Piece Construction | ASME BPE | 0000000 | 000000 |

2205 Stainless Steel Ring with Glass Window | ||||||||||

| 1", 1 1/2" | 1.98" | 1" | 230 psi @ 70° F | -40° | 500° | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid, Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | One-Piece Construction | ASME BPE, ASTM A479, DIN 7079, DIN 7080, TUV Rheinland Certified, USP Class VI | 0000000 | 000000 |

| 2" | 2.52" | 1 3/16" | 230 psi @ 70° F | -40° | 500° | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid, Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | One-Piece Construction | ASME BPE, ASTM A479, DIN 7079, DIN 7080, TUV Rheinland Certified, USP Class VI | 0000000 | 000000 |

| 3" | 3.58" | 1 1/2" | 150 psi @ 70° F | -40° | 500° | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid, Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | One-Piece Construction | ASME BPE, ASTM A479, DIN 7079, DIN 7080, TUV Rheinland Certified, USP Class VI | 0000000 | 000000 |

| 4" | 4.68" | 2 3/16" | 150 psi @ 70° F | -40° | 500° | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid, Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | One-Piece Construction | ASME BPE, ASTM A479, DIN 7079, DIN 7080, TUV Rheinland Certified, USP Class VI | 0000000 | 000000 |

Easy-View Oil-Level Indicators

Made with clear, shatter-resistant plastic, these indicators don't require a shield to protect them like other oil-level indicators, so you can check your hydraulic fluid or oil level from any angle. They’re often found on gear boxes, crank cases, and other reservoirs. These indicators mount from the outside of your tank. The vent prevents pressure buildup, which can affect the level displayed. Within the vent, there is a filter for keeping out particles as small as table salt. Unthread the vent to clean its filter or to replace it with your own vent, plug, fitting, or sensor. These indicators also have adjustable rings for marking levels critical to your system.

Temp. Range, °F | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Overall Ht. | Window Ht. | Max. Pressure | Min. | Max. | Fitting Material | Window Material | Features | Includes | Each | |

Copolyester Plastic | ||||||||||

3/8 NPT Male Thread | ||||||||||

| 3 3/4" | 1 7/8" | 65 psi @ 70° F | -40° | 200° | Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 000000 |

| 6 3/4" | 4 7/8" | 65 psi @ 70° F | -40° | 200° | Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 9 3/4" | 7 7/8" | 65 psi @ 70° F | -40° | 200° | Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 12 3/4" | 10 7/8" | 65 psi @ 70° F | -40° | 200° | Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 18 3/4" | 16 7/8" | 65 psi @ 70° F | -40° | 200° | Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 000000 |

1/2 NPT Male Thread | ||||||||||

| 3 13/16" | 1 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 6 13/16" | 4 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 9 13/16" | 7 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 12 13/16" | 10 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 18 13/16" | 16 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 000000 |

3/4 NPT Male Thread | ||||||||||

| 3 13/16" | 1 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 6 13/16" | 4 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 9 13/16" | 7 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 12 13/16" | 10 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 00000 |

| 18 13/16" | 16 7/8" | 65 psi @ 70° F | -40° | 200° | 304 Stainless Steel | Copolyester Plastic | 3-Micron Filter, UV Resistant, Vent | Level Rings | 0000000 | 000000 |

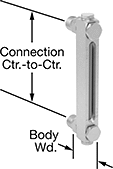

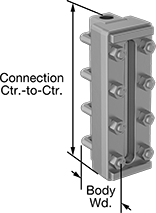

Chemical-Level Indicators

Check the level of liquids containing chemicals such as alcohol-based solvents, boric acid, and sodium bicarbonate. These indicators can be used in pressurized applications where overflow is a concern. All have an aluminum gauge shield that protects the glass window from impact. Clear liquids magnify a red line at the back of the window, so their levels are easier to see.

Screw-in indicators mount from the outside of your tank into threaded pipe or threaded holes.

Through-wall indicators mount from the inside of your tank through unthreaded holes. Secure with nuts on the inside of your tank.

Screw-in/through-wall indicators give you the option to mount from the inside or outside of your tank. Use the mounting nuts on the inside of your tank to attach them through unthreaded holes or thread them into pipe or threaded holes on the tank’s outside.

Temp. Range, °F | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Connection Ctr.-to-Ctr. | Overall Ht. | Window Ht. | Body Wd. | For Max. Tank Wall Thick. | Max. Pressure | Min. | Max. | Fitting Material | Window Material | Features | Includes | Each | |

Screw-In Mount—Aluminum | |||||||||||||

3/8 NPTF Male Thread | |||||||||||||

| 3" | 4 5/8" | 1 1/2" | 1 3/4" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 000000 |

1/2 NPTF Male Thread | |||||||||||||

| 6" | 7 5/8" | 4 1/2" | 1 9/16" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 8" | 9 5/8" | 6 1/2" | 1 9/16" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 1 9/16" | __ | 275 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 1 9/16" | __ | 270 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

Through-Wall Mount—Aluminum | |||||||||||||

1/2"-20 UNF Male Thread—For 1/2" Hole Dia. (2 Holes) | |||||||||||||

| 5" | 6 5/8" | 3 1/2" | 7/8" | 3/4" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 7/8" | 3/4" | 275 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 7/8" | 3/4" | 270 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

Screw-In/Through-Wall Mount—Aluminum | |||||||||||||

1/2"-20 UNF Male Thread—For 1/2" Hole Dia. (2 Holes) | |||||||||||||

| 3" | 4 5/8" | 1 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 5" | 6 5/8" | 3 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 6" | 7 5/8" | 4 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 8" | 9 5/8" | 6 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 1 1/8" | 1/2" | 275 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 1 1/8" | 1/2" | 270 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

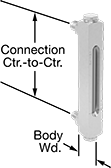

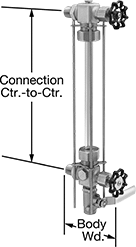

Level Indicators with Shut-Off Valve

Shut-off valves stop flow so you can clean and replace gauge glass without removing these indicators from your equipment.

316 stainless steel indicators are more corrosion resistant than brass or bronze indicators. They have a stainless steel drain valve and be used on expansion tanks.

Indicators with automatic shut-off will temporarily close if the gauge glass breaks. The valves must be closed manually for permanent shut-off.

Level Indicators | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. Range, °F | Replacement Glass | ||||||||||||||

| Connection Ctr.-to-Ctr. | Overall Ht. | Window Ht. | Body Wd. | Drain Cock Dia. | Max. Pressure | Max. Steam Pressure | Min. | Max. | For Use With | No. of Guard Rods | Specifications Met | Each | Each | ||

316 Stainless Steel | |||||||||||||||

1/2 NPT Male Thread with Ball-Valve-Style Drain and Automatic Shut-Off | |||||||||||||||

| 14" | 18 1/16" | 10" | 4 7/8" | 1/4" | 410 psi @ 70° F | 305 psi @ 400° F | 35° | 400° | Water, Hydraulic Fluid, Acetic Acid, Alcohol-Based Solvents, Ketone, Steam | 4 | ASME BPVC.I | 0000000 | 000000000 | 0000000 | 000000 |

3/4 NPT Male Thread with Ball-Valve-Style Drain and Automatic Shut-Off | |||||||||||||||

| 18" | 22 1/16" | 12" | 4 13/16" | 1/4" | 370 psi @ 70° F | 280 psi @ 400° F | 35° | 400° | Water, Hydraulic Fluid, Acetic Acid, Alcohol-Based Solvents, Ketone, Steam | 4 | ASME BPVC.I | 0000000 | 00000000 | 0000000 | 00000 |

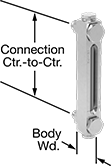

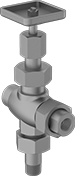

Heavy Duty Level Indicators

Monitor liquid level in applications that have vibration, high pressures, and high temperatures. These indicators have steel chambers, glass windows, and seals made of fiber and SBR rubber to resist corrosion and withstand higher temperatures than other level indicators. Use them with a wide variety of liquids, such as petroleum, chemicals, and natural gas. All meet ASME BPVC.VIII.1 safety standards for pressure vessels, so they’re approved for use in low-pressure water and steam applications too. Their gauge is made of reflex glass, which shows the level of liquid behind the glass, but not the liquid’s color or any particulates in it. Also known as armored level gauges.

Add shut-off valves to stop flow with the turn of a wheel. They help you access indicators in order to clean or replace the glass or the entire indicator. These valves also stop flow automatically if the indicator glass breaks, preventing the loss of fluid. However, for permanent shut-off you must close them manually. Put one valve on top of your indicator and one on the bottom for a 90° connection between the indicator and your tank. To connect the female threads on your indicator to the female gauge threads on the shut-off valve, use a male pipe nipple (not included).

Indicators | Shut-Off Valves | Replacement Glass | Replacement Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Glass Size | Connection Center-to-Center | Overall Height | Window Height | Body Width | Maximum Pressure | Temperature Range, °F | Each | Each | Each | Each | ||||

Steel Indicator with Reflex Glass | ||||||||||||||

1/2 NPT Female Thread | ||||||||||||||

| 4 | 8 1/4" | 16 1/2" | 6 3/4" | 3 3/4" | 2,725 psi @ 70° F | -20° to 600° | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 00000 |

| 5 | 9 3/8" | 18 3/4" | 7 7/8" | 3 3/4" | 2,630 psi @ 70° F | -20° to 600° | 00000000 | 00000000 | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 0000 |

| 6 | 10 5/8" | 10 5/8" | 9 1/8" | 3 3/4" | 2,535 psi @ 70° F | -20° to 600° | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 0000 |

| 7 | 11 3/4" | 11 3/4" | 10 1/4" | 3 3/4" | 2,440 psi @ 70° F | -20° to 600° | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 0000 |

| 8 | 13 3/8" | 13 3/8" | 11 7/8" | 3 3/4" | 2,345 psi @ 70° F | -20° to 600° | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 0000 |

| 9 | 14 1/8" | 14 1/8" | 12 5/8" | 3 3/4" | 2,250 psi @ 70° F | -20° to 600° | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 0000 |

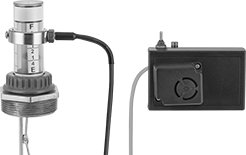

Vertical-Mount Liquid-Level Gauges for Tanks

For use with water, hydraulic fluid, and diesel fuel, install these gauges through the top of your tank. All have an indicator that moves up as the tank fills. To see how full your tank is and if you need to fill or drain it, check the indicator against the graduation marks. Plastic protects the indicator's movement, saving you from inaccurate readings.

Alarms can be set to flash and sound at levels critical to your system.

Remote-reading displays let you check readings from up to 100 ft. away. They have an alarm that sounds when the level is too high or too low.

Temp. Range, °F | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tank Dp. | Max. Pressure, psi | Window Ht. | Min. | Max. | Float Material | Graduation Marks | Window Material | Each | |

1 1/2 NPT Male | |||||||||

Zinc-Plated Steel Float Rod | |||||||||

| 8" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 000000 |

| 9" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 10" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 11" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 12" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 13" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 14" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 15" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 16" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 17" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 18" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 19" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 20" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 21" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 22" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 23" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 24" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 25" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 26" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 27" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 28" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 29" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 30" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 31" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 32" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 33" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 34" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 35" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 36" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 37" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 38" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 39" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 40" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 41" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 42" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 43" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 44" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 45" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 46" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 47" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 48" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 49" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 50" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 51" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 52" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 53" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 54" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 55" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 56" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 57" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 58" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 59" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 60" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 61" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 62" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 63" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 64" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 65" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 66" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 67" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 68" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 69" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 70" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 71" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 72" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 000000 |

2 NPT Male | |||||||||

Zinc-Plated Steel Float Rod | |||||||||

| 8" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 9" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 10" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 11" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 12" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 13" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 14" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 15" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 16" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 17" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 18" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 19" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 20" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 21" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 22" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 23" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 24" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 25" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 26" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 27" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 28" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 29" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 30" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 31" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 32" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 33" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 34" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 35" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 36" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 37" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 38" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 39" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 40" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 41" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 42" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 43" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 44" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 45" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 46" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 47" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 48" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 49" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 50" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 51" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 52" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 53" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 54" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 55" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 56" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 57" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 58" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 59" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 60" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 61" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 62" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 63" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 64" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 65" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 66" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 67" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 68" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 69" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 70" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 71" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 00000 |

| 72" | 70 | 3" | -20° | 110° | Polyethylene Plastic | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 00000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Color | Pattern | No. of | Bulb Type | Volume | Housing Material | Batteries Included | Each | |

Direct Mount | ||||||||||

| __ | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 0000000 |

Remote Mount | ||||||||||

| 25 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 50 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Display Type | Color | Indicator Display Type | No. of | Volume | Housing Material | Batteries Included | Each | |

| 25 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 0000000 |

| 50 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

Chemical-Resistant Vertical-Mount Liquid-Level Gauges for Tanks

With a stainless steel float and float rod, these gauges resist corroding from chemicals. Their indicator moves up as your tank fills. Check the indicator against the graduation marks to see how full your tank is and if you need to fill or drain it. Plastic protects the indicator's movement, saving you from inaccurate readings.

Alarms can be set to flash and sound at levels critical to your system.

Remote-reading displays let you check readings from up to 100 ft. away. They have an alarm that sounds when the level is too high or too low.

Temp. Range, °F | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tank Dp. | Max. Pressure, psi | Window Ht. | Min. | Max. | Float Material | Graduation Marks | Window Material | Each | |

1 1/2 NPT Male | |||||||||

316 Stainless Steel Float Rod | |||||||||

| 12" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 0000000 |

| 20" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 24" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 30" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 36" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 48" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

2 NPT Male | |||||||||

316 Stainless Steel Float Rod | |||||||||

| 12" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 20" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 24" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 30" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 36" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 42" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 48" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 60" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Color | Pattern | No. of | Bulb Type | Volume | Housing Material | Batteries Included | Each | |

Direct Mount | ||||||||||

| __ | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 0000000 |

Remote Mount | ||||||||||

| 25 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 50 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Display Type | Color | Indicator Display Type | No. of | Volume | Housing Material | Batteries Included | Each | |

| 25 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 0000000 |

| 50 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |