Filter by

Attachment Type

Wire Rope Construction

End Fitting Type

REACH

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

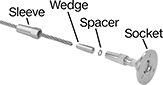

Mounting-Plate-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Overall Lg. | Sleeve Dia. | Max. Pivot Angle | No. of Mounting Holes | For Screw Size | Mounting Fasteners Included | Rope Cap. Adjustment Factor | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swiveling End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/4" | 13/32" | 45° | 3 | No. 8 | Yes | 80% | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

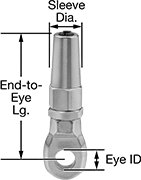

Eye-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

For Wire Rope | Eye | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-Eye Lg. | ID | Thk. | Sleeve Dia. | Wt. Cap. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 7/8" | 1/4" | 15/64" | 9/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 9/32" | 3/8" | 9/32" | 5/8" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 21/32" | 7/16" | 5/16" | 3/4" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/8" | 1/2" | 23/64" | 27/32" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 25/32" | 9/16" | 27/64" | 1 1/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 7/16" | 11/16" | 33/64" | 1 3/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

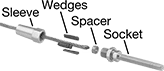

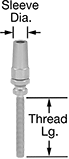

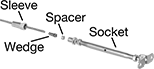

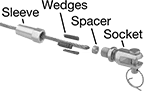

Stud-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

For Wire Rope | Thread | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Overall Lg. | Size | Lg. | Sleeve Dia. | Wt. Cap. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/4" | 1/4"-28 | 1 27/32" | 17/32" | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 6 5/8" | 1/4"-28 | 1 27/32" | 5/8" | Not Rated | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 3/8" | 5/16"-24 | 2 1/4" | 23/32" | Not Rated | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 5 1/32" | 3/8"-24 | 2 15/32" | 27/32" | Not Rated | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 6 3/8" | 1/2"-20 | 3 5/32" | 1 1/16" | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 7 13/32" | 5/8"-18 | 3 15/16" | 1 3/16" | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed-Body Mounting-Plate-to-Wire Rope Turnbuckles—Not for Lifting

316 Stainless Steel Body with 316 Stainless Steel End Fitting

Mounting Plate | For Wire Rope | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Rope Cap. Adjustment Factor | Retracted Lg. | Max. Adjustment | Extended Lg. | Lg. | Wd. | Movement | Thread Size | Dia. | Construction | Wire Rope Fitting Type | No. of Mounting Holes | Mounting Hole Dia. | Mounting Fasteners Included | Each | |||

| 70% | 4 1/16" | 1 3/8" | 5 7/16" | 1 1/2" | 1 1/2" | 360° Swivel | 1/4"-28 | 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 3 | 0.164" | Yes | 000000 | 000000 | ||

| 70% | 6 7/8" | 2 1/2" | 9 3/8" | 2 1/8" | 5/8" | 360° Swivel | 1/4"-28 | 1/8" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.244" | Yes | 0000000 | 00000 | ||

| 70% | 7 3/4" | 3" | 10 3/4" | 2 13/16" | 13/16" | 360° Swivel | 5/16"-24 | 3/16" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.318" | Yes | 0000000 | 00000 | ||

| 70% | 9" | 3 7/16" | 12 7/16" | 3 1/16" | 7/8" | 360° Swivel | 3/8"-24 | 1/4" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.394" | Yes | 0000000 | 000000 | ||

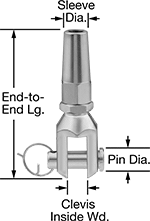

Clevis-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

|  |

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-End Lg. | Clevis Inside Wd. | Sleeve Dia. | Pin Dia. | Wt. Cap. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 7/16" | 1/4" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 7/8" | 5/16" | 1/2" | 5/16" | Not Rated | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/4" | 7/16" | 9/16" | 7/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 3/4" | 1/2" | 5/8" | 1/2" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 11/16" | 9/16" | 3/4" | 9/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 5 1/4" | 11/16" | 1" | 11/16" | Not Rated | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||