Filter by

System of Measurement

Plain Bearing Type

For Housing ID

Bearing Type

Lubrication

Dynamic Radial Load Capacity @ Speed

For Load Direction

Performance

Maximum Temperature

Shaft Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Minimum Temperature

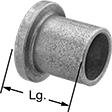

Sleeve Bearings

|

These bearings don’t come with a lubricant, so you can select the oil that meets the needs of your application. You’ll need to refill the oil, so make sure the bearing is located where you can access it. All are fabricated and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength 932 Bearing Bronze—These bearings are strong enough for sudden starts and stops, plus they resist wear and tear. They are cast from an alloy of leaded tin bronze for uniform rigidity and strength. Also known as 660 leaded bronze bearings.

High-Strength Chemical-Resistant 954 Bearing Bronze—The strongest of our bronze bearings. The addition of iron and aluminum makes them exceptionally strong and resistant to chemicals. They’re often used in the most demanding environments, such as salt mines. Also known as aluminum bronze.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 30 | 25 | 3,100 lb. @ 60 rpm | -350 to 450 | 7811K238 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 30 | 75 | 9,300 lb. @ 60 rpm | -350 to 450 | 7811K239 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 12 | 1,850 lb. @ 60 rpm | -350 to 450 | 7811K253 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 3,100 lb. @ 60 rpm | -350 to 450 | 7811K56 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 3,850 lb. @ 60 rpm | -350 to 450 | 7811K254 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 4,650 lb. @ 60 rpm | -350 to 450 | 7811K255 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 50 | 7,750 lb. @ 60 rpm | -350 to 450 | 7811K257 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 55 | 8,500 lb. @ 60 rpm | -350 to 450 | 7811K258 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 65 | 10,050 lb. @ 60 rpm | -350 to 450 | 7811K259 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 100 | 15,500 lb. @ 60 rpm | -350 to 450 | 7811K252 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 3,450 lb. @ 60 rpm | -350 to 500 | 2867T138 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 50 | 8,700 lb. @ 60 rpm | -350 to 500 | 2867T139 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 75 | 13,050 lb. @ 60 rpm | -350 to 500 | 2867T141 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Flanged Sleeve Bearings

|

Made of naturally slippery plastic so you’ll never have to add lubricant. They’re ideal for clean environments where you need to prevent oil drips or graphite flakes. Compared to metal bearings, they are lighter and will never rust.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

Ultra-Chemical-Resistant PTFE—The most chemical-resistant bearings we offer. PTFE is unaffected by the harsh fluids that other plastics can't handle, including all strong acids and bases. PTFE also reduces friction better than nylon but is not as strong.

Moisture-Resistant Ultra-Low-Friction Plastic Blend—These bearings won't warp or swell from humidity or direct contact with water. They glide effortlessly for applications with frequent starts and stops, such as conveyor systems.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Color | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 50 lb. @ 60 rpm | 33 lb. @ 60 rpm | White | -200 to 450 | FDA Compliant 21 CFR 177.1550 | 2706T574 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 39 | 3.5 | 75 lb. @ 60 rpm | 45 lb. @ 60 rpm | White | -200 to 450 | FDA Compliant 21 CFR 177.1550 | 2706T576 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture-Resistant Ultra-Low-Friction Plastic Blend | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 30 | 30 | 36 | 3 | 720 lb. @ 60 rpm | 380 lb. @ 60 rpm | Yellow | -50 to 190 | — | 2705T172 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Metal-Reinforced Plastic Sleeve Bearings

|

Combine slippery plastic with the strength of metal. The PTFE core is naturally slippery, so you’ll never have to add lubricant. These bearings also keep your workspace clean with no lubricant to drip or flake and attract dust. Compared to all-metal bearings, they are lighter.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

PTFE with Aluminum Shell—A lightweight upgrade from our steel shell. These bearings also offer good corrosion resistance similar to stainless steel but aren’t as strong.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PTFE with Aluminum Shell | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 1,250 lb. @ 60 rpm | -400 to 400 | 7751K59 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Sleeve Bearings for Food and Beverage

|

Made of plastics permitted by the US FDA for contact with food, these bearings won’t release harmful, smelly, and distasteful impurities into your food or beverage production line. These self-lubricating plastics eliminate the need for oil, resulting in less maintenance and improved hygiene. You’ll find them inside food-processing equipment such as mixers, conveyors, and fillers.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

Moisture-Resistant UHMW Polyethylene—Virtually nonabsorbent, these bearings will keep their shape after washdowns. However, they aren’t suitable for high-temperature treatments such as steam cleaning.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Moisture-Resistant UHMW Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 100 lb. @ 60 rpm | White | -200 to 180 | FDA Compliant 21 CFR 177.1520 | 6657K4 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vibration-Damping Oil-Embedded Sleeve Bearings

|

These bearings quiet equipment by absorbing vibration. The rubber layer on the inside of these bearings flexes to align the shaft and reduce rattling. The bronze core is made from porous metal and saturated with oil to reduce maintenance and downtime. They’re used in compressors, engine mounts, and other vibrating equipment that suddenly starts and stops.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze with 304 Stainless Steel Shell—The choice for most wet locations. These bearings won't corrode after washdowns and can stand up to most detergents and oil.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Cushion Material | Base Oil | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze with 304 Stainless Steel Shell | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 30 | 30 | 370 lb. @ 60 rpm | Silicone Rubber | Synthetic Oil | -35 to 300 | 6364K53 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Sleeve Bearings

|

Install and forget these self-lubricating bearings. All are made from porous metal and saturated with oil to reduce maintenance and downtime. A good all-around choice, they are used in everything from palm-sized fans in

electronics to tire-sized pulleys. Although these bearings will work in most conditions, oil may drip away if temperatures get too high. Consider a graphite-lubricated bearing for higher temperatures or places where you can’t

afford the mess. All are fabricated, lubricated, and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

High-Strength 863 Iron Copper—Iron makes these bearings harder, stronger, and more resistant to sudden starts and stops than 841 bearing bronze. However, they operate at slower speeds. The increased iron content makes these bearings appear silver.

Extreme-Strength Heat-Treated Iron Copper—Our strongest oil-embedded sleeve bearings. They’re heat treated to form a uniform internal grain that makes them stronger than 863 iron copper. As a result, they’re often used to support extreme loads in earth-moving equipment and railroad applications. The increased iron content makes these bearings appear silver.

Mineral Oil Base—Mineral oil consistently lubricates at most temperatures but doesn’t last as long as synthetic oil.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures. Also known as Oilite® bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 1,550 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K56 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 1,900 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K749 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 28 | 2,150 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K246 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 2,300 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K751 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 40 | 3,100 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K247 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 50 | 3,850 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6658K248 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 1,750 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2868T385 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 2,150 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2868T386 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 2,600 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2868T387 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Strength Heat-Treated Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 5,600 lb. @ 60 rpm | Mineral Oil | 10 to 220 | 6995N196 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 40 | 7,500 lb. @ 60 rpm | Mineral Oil | 10 to 220 | 6995N197 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Sleeve Bearings

|

Made of naturally slippery plastic so you’ll never have to add lubricant. They’re ideal for clean environments where you need to prevent oil drips or graphite flakes. Compared to metal bearings, they are lighter and will never rust.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength Moisture-Resistant Rulon LR—Won’t swell in wet or humid places, similar to acetal, but can support higher loads. These bearings also operate smoothly from cryogenic to oven-like temperatures.

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Moisture-Resistant Rulon LR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 500 lb. @ 60 rpm | Maroon | -400 to 550 | 7763K56 | 000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grooved Sleeve Bearings

|

A figure-8-shaped groove provides a flow path for lubricant and distributes it evenly inside the bearing’s surface. A refill hole on the outside lets you inject your lubricant straight into the groove. These bearings don’t come with a lubricant, so you can select the oil that meets the needs of your application. You’ll need to refill the oil, so make sure the bearing is located where you can access it. All are fabricated and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength 932 Bearing Bronze—These bearings are strong enough for sudden starts and stops, plus they resist wear and tear. They are cast from an alloy of leaded tin bronze for uniform rigidity and strength. Also known as 660 leaded bronze bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 2,700 lb. @ 60 rpm | -350 to 450 | 7965K829 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 3,350 lb. @ 60 rpm | -350 to 450 | 7965K831 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 4,050 lb. @ 60 rpm | -350 to 450 | 7965K832 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 65 | 8,800 lb. @ 60 rpm | -350 to 450 | 7965K835 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Metal-Reinforced Plastic Flanged Sleeve Bearings

|

Combine slippery plastic with the strength of metal. The PTFE core is naturally slippery, so you’ll never have to add lubricant. These bearings also keep your workspace clean with no lubricant to drip or flake and attract dust. Compared to all-metal bearings, they are lighter.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

PTFE with Aluminum Shell—Made of a lightweight shell with corrosion resistance similar to stainless steel and a slippery PTFE inner sleeve.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PTFE with Aluminum Shell | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 39 | 4 | 1,000 lb. @ 60 rpm | 900 lb. @ 60 rpm | -400 to 400 | 7751K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 39 | 4 | 1,250 lb. @ 60 rpm | 900 lb. @ 60 rpm | -400 to 400 | 7751K79 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

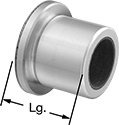

Flanged Sleeve Bearings

|

These bearings don’t come with a lubricant, so you can select the oil that meets the needs of your application. You’ll need to refill the oil, so make sure the bearing is located where you can access it. All are fabricated and inspected in the U.S.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength 932 Bearing Bronze—These bearings are strong enough for sudden starts and stops, plus they resist wear and tear. They are cast from an alloy of leaded tin bronze for uniform rigidity and strength. Also known as 660 leaded bronze bearings.

High-Strength Chemical-Resistant 954 Bearing Bronze—The strongest of our bronze bearings. The addition of iron and aluminum makes them exceptionally strong and resistant to chemicals. They’re often used in the most demanding environments, such as salt mines. Also known as aluminum bronze.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 39 | 3.5 | 3,100 lb. @ 60 rpm | 3,350 lb. @ 60 rpm | -350 to 450 | 5448T26 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 39 | 3.5 | 3,850 lb. @ 60 rpm | 3,350 lb. @ 60 rpm | -350 to 450 | 5448T457 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 3,450 lb. @ 60 rpm | 3,250 lb. @ 60 rpm | -350 to 500 | 2934T158 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 35 | 2.5 | 4,350 lb. @ 60 rpm | 3,250 lb. @ 60 rpm | -350 to 500 | 2934T159 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 35 | 2.5 | 5,200 lb. @ 60 rpm | 3,250 lb. @ 60 rpm | -350 to 500 | 2934T161 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 40 | 35 | 2.5 | 6,950 lb. @ 60 rpm | 3,250 lb. @ 60 rpm | -350 to 500 | 2934T162 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Sleeve Bearings

|

Made of a graphite and metal alloy, these bearings stay slippery at high temperatures where oil burns off and other bearings fail. With no need for refills, they require little to no maintenance. You’ll find them in pumps, propellers, and mixers that spin near steam or inside ovens. However, graphite may eventually flake off, dropping flecks and leaving smudges. If you need a spic-and-span space, consider dry-running bearings made of slippery plastic instead. All are fabricated, lubricated, and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength 932 Bearing Bronze—These bearings are strong enough for sudden starts and stops, plus they resist wear and tear. They are cast from an alloy of leaded tin bronze for uniform rigidity and strength. Also known as 660 leaded bronze bearings.

High-Strength Chemical-Resistant 954 Bearing Bronze—The strongest of our bronze bearings. The addition of iron and aluminum makes them exceptionally strong and resistant to chemicals. They’re often used in the most demanding environments, such as salt mines. Also known as aluminum bronze.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 2,700 lb. @ 60 rpm | -350 to 450 | 6405K429 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 4,050 lb. @ 60 rpm | -350 to 450 | 6405K439 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 40 | 5,400 lb. @ 60 rpm | -350 to 450 | 6405K423 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 50 | 6,750 lb. @ 60 rpm | -350 to 450 | 6405K434 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 40 | 6,000 lb. @ 60 rpm | -350 to 500 | 2927T102 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 50 | 7,550 lb. @ 60 rpm | -350 to 500 | 2927T125 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Sleeve Bearings for Food and Beverage

|

These lead-free bearings are infused with a food-grade oil that is odorless, colorless, tasteless, and safe for unintended contact with food. They’re often used in food and beverage processing, packing, and handling equipment. All are made from porous metal and saturated with oil to reduce maintenance and downtime. If you need a bearing rated for contact with food, consider dry-running sleeve bearings for food and beverage. All are fabricated, lubricated, and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

High-Strength 863 Iron Copper—Iron makes these bearings harder, stronger, and more resistant to sudden starts and stops than 841 bearing bronze. However, they operate at slower speeds. The increased iron content makes these bearings appear silver.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures. Also known as Oilite® bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 2,300 lb. @ 60 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570 | 7095K197 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 1,750 lb. @ 60 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570, ASTM B439 | 7407N195 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 2,150 lb. @ 60 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570, ASTM B439 | 7407N196 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Flanged Sleeve Bearings

|

Our slipperiest metal bearings, these are ideal for machinery with frequent starts and stops, such as conveyors. With nonstick PTFE particles added to the oil, they reduce friction to minimize wear and heat, so equipment runs more efficiently and lasts longer. All are fabricated, lubricated, and inspected in the U.S.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

High-Strength 863 Iron Copper—Iron makes these bearings harder, stronger, and more resistant to sudden starts and stops than 841 bearing bronze. However, they operate at slower speeds. The increased iron content makes these bearings appear silver.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 1,500 lb. @ 60 rpm | 1,450 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 1677K279 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 1,750 lb. @ 60 rpm | 1,150 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7119N178 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 39 | 3.5 | 2,600 lb. @ 60 rpm | 1,550 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7119N181 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Sleeve Bearings

|

Our slipperiest metal bearings, these are ideal for machinery with frequent starts and stops, such as conveyors. With nonstick PTFE particles added to the oil, they reduce friction to minimize wear and heat, so equipment runs more efficiently and lasts longer. All are fabricated, lubricated, and inspected in the U.S.

With no moving parts, sleeve bearings are the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

High-Strength 863 Iron Copper—Iron makes these bearings harder, stronger, and more resistant to sudden starts and stops than 841 bearing bronze. However, they operate at slower speeds. The increased iron content makes these bearings appear silver.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures. Also known as Oilite® bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 1,500 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 1688K195 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 1,900 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 1688K196 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 2,300 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 1688K197 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 1,750 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7460N195 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 2,150 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7460N196 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 2,600 lb. @ 60 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7460N197 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Flanged Sleeve Bearings

|

Made of a graphite and metal alloy, these bearings stay slippery at high temperatures where oil burns off and other bearings fail. With no need for refills, they require little to no maintenance. You’ll find them in pumps, propellers, and mixers that spin near steam or inside ovens. However, graphite may eventually flake off, dropping flecks and leaving smudges. If you need a spic-and-span space, consider dry-running bearings made of slippery plastic instead. All are fabricated, lubricated, and inspected in the U.S.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

High-Strength 932 Bearing Bronze—These bearings are strong enough for sudden starts and stops, plus they resist wear and tear. They are cast from an alloy of leaded tin bronze for uniform rigidity and strength. Also known as 660 leaded bronze bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Strength 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 3,100 lb. @ 60 rpm | 2,500 lb. @ 60 rpm | -350 to 450 | 2962T151 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Flanged Sleeve Bearings for Food and Beverage

|

These lead-free bearings are infused with a food-grade oil that is odorless, colorless, tasteless, and safe for incidental contact with food. They’re often used in food and beverage processing, packing, and handling equipment. All are made from porous metal and saturated with oil to reduce maintenance and downtime. If you need a bearing rated for direct contact with food, consider dry-running flanged sleeve bearings for food and beverage. All are fabricated, lubricated, and inspected in the U.S.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 39 | 3.5 | 1,900 lb. @ 60 rpm | 2,150 lb. @ 60 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570 | 3746K111 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 39 | 3.5 | 2,300 lb. @ 60 rpm | 2,150 lb. @ 60 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570 | 3746K112 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Flanged Sleeve Bearings

|

Install and forget these self-lubricating bearings. All are made from porous metal and saturated with oil to reduce maintenance and downtime. A good all-around choice, they are used in everything from palm-sized fans in electronics to tire-sized pulleys. Although these bearings will work in most conditions, oil may drip away if temperatures get too high. Consider a graphite-lubricated bearing for higher temperatures or places where you can’t afford the mess. All are fabricated, lubricated, and inspected in the U.S.

Flanged sleeve bearings combine a sleeve and thrust bearing in one. The flange supports thrust loads and prevents the bearing from being pushed out of place. The sleeve is the simplest way to support the load of a rotating shaft while reducing friction. Also known as plain bearings.

841 Bearing Bronze—A classic choice for a starter pick. Also known as SAE 841 bearings.

High-Strength 863 Iron Copper—Iron makes these bearings harder, stronger, and more resistant to sudden starts and stops than 841 bearing bronze. However, they operate at slower speeds. The increased iron content makes these bearings appear silver.

Synthetic Oil Base—A high-quality lubricant makes all the difference. Synthetic oil is less sensitive to temperature changes than mineral oil, so it won't get runny and leak away at higher temperatures. Also known as Oilite® bearings.

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 1,550 lb. @ 60 rpm | 1,450 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6659K53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 39 | 3.5 | 1,900 lb. @ 60 rpm | 2,150 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6659K691 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 39 | 3.5 | 2,300 lb. @ 60 rpm | 2,150 lb. @ 60 rpm | Synthetic Oil | -35 to 300 | 6659K711 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 20 | 35 | 2.5 | 1,750 lb. @ 60 rpm | 1,150 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2938T81 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 25 | 39 | 3.5 | 2,150 lb. @ 60 rpm | 1,550 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2938T811 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 30 | 30 | 39 | 3.5 | 2,600 lb. @ 60 rpm | 1,550 lb. @ 60 rpm | Synthetic Oil | -15 to 300 | 2938T812 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||