Filter by

System of Measurement

Screw Size

For Bearing Nut Face Style

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Hardness

Application

Construction

Filler Material

For Bearing Nut Specifications Met

Height

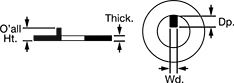

Overall Height

Sealing Washers

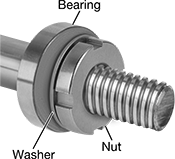

Bearing Spring Lock Washers for Slotted Bearing Nuts

Tab, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Wd. | Dp. | Overall Ht., mm | Hardness | Specs. Met | For Bearing Nut Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Stepped Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M38 | 38.000 | 58.000 | 1.200 | 8.000 | 2.500 | 5.000 | Not Rated | DIN 462 | DIN 1804 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||