Metric-to-Metric Male Hex Thread Adapters

Twist these adapters onto female metric threads to change pitch or switch thread sizes. They can also be used as standoffs to make space between parts. Tighten or loosen with a wrench.

Adapters that meet ASTM specifications are made from or plated with materials that adhere to specific standards for chemical and physical properties, such as hardness.

At one third the weight of steel, aluminum adapters are the lightest option. They will not rust in damp or humid environments, but they will corrode if left in water.

18-8 stainless steel adapters can be used in wet environments, but chemicals or salt water will cause staining and rust spots.

For areas exposed to salt water or chemicals, 316 stainless steel adapters are the best choice. Only harsh chemicals, such as hydrochloric acid, will cause them to corrode.

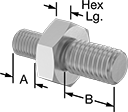

Thread Size | Thread Lg. | Thread Fit | Hex | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (A) | Pitch (A), mm | (B) | Pitch (B), mm | (A), mm | (B), mm | (A) | (B) | Size, mm | Lg., mm | Tensile Strength, psi | Hardness | Specifications Met | Each | |

Aluminum | ||||||||||||||

| M6 | 1 | M8 | 1 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 45,000 | Rockwell B56 | ASTM B211 | 000000000 | 00000 |

| M8 | 1 | M8 | 1.25 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 45,000 | Rockwell B56 | ASTM B211 | 000000000 | 0000 |

18-8 Stainless Steel | ||||||||||||||

| M6 | 0.75 | M8 | 1 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 85,000 | Rockwell B80 | ASTM A582 | 000000000 | 0000 |

| M6 | 1 | M8 | 1 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 85,000 | Rockwell B80 | ASTM A582 | 000000000 | 0000 |

316 Stainless Steel | ||||||||||||||

| M6 | 0.75 | M8 | 1 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 75,000 | Rockwell B83 | ASTM A276 | 000000000 | 00000 |

| M6 | 1 | M8 | 1 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 75,000 | Rockwell B83 | ASTM A276 | 000000000 | 00000 |

| M6 | 1 | M8 | 1.25 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 75,000 | Rockwell B83 | ASTM A276 | 000000000 | 00000 |

| M8 | 1 | M8 | 1.25 | 12.7 | 12.7 | Class 6g | Class 6g | 12.7 | 4.8 | 75,000 | Rockwell B83 | ASTM A276 | 000000000 | 00000 |