Filter by

Specific Gravity

Measurement Unit

For Use With

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Gravity

Density Meters

Range | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Measurement Unit | Gravity | Specific Gravity | Saturation | Concentration | Graduations | Material | Lg. | OD | Features | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Heavy Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baume | 0 ° Bé to 25 ° Bé | — | — | — | 0.5 ° Bé | Glass | 12" | 3/4" | — | — | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baume | 0 ° Bé to 50 ° Bé | — | — | — | 1 ° Bé | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baume | 0 ° Bé to 70 ° Bé | — | — | — | 1 ° Bé | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baume, Specific Gravity | 0 ° Bé to 72 ° Bé | 1 to 2 | — | — | 1 ° Bé, 0.010 | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 1.07 | — | — | 0.0005 | Glass | 13" | 13/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 1.22 | — | — | 0.002 | Glass | 12" | 11/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 1.22 | — | — | 0.002 | Glass | 12" | 13/16" | Built-In Thermometer | 20 to 150 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 1.6 | — | — | 0.005 | Glass | 12" | 13/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 2 | — | — | 0.010 | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1.2 to 1.42 | — | — | 0.002 | Glass | 12" | 11/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1.24 to 1.31 | — | — | 0.0005 | Glass | 13" | 1" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1.6 to 1.82 | — | — | 0.002 | Glass | 12" | 11/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plato | 0 ° Plato to 8.5 ° Plato | — | — | — | 0.1 ° Plato | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plato | 7.5 ° Plato to 16.5 ° Plato | — | — | — | 0.1 ° Plato | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plato | 15.5 ° Plato to 24 ° Plato | — | — | — | 0.1 ° Plato | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Light Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baume, Specific Gravity | 10 ° Bé to 100 ° Bé | 0.6 to 1 | — | — | 1 ° Bé, 0.005 | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.5 to 0.65 | — | — | 0.001 | Glass | 14" | 1" | Built-In Thermometer | 30 to 90 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.65 to 1 | — | — | 0.005 | Glass | 12" | 9/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.7 to 0.77 | — | — | 0.0005 | Glass | 13" | 1" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.7 to 0.81 | — | — | 0.001 | Glass | 12" | 13/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.8 to 0.91 | — | — | 0.001 | Glass | 12" | 11/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 0.9 to 1 | — | — | 0.001 | Glass | 12" | 11/16" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 19 ° API to 31 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 29 ° API to 41 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 39 ° API to 51 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 49 ° API to 61 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 59 ° API to 71 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| API Gravity | 69 ° API to 81 ° API | — | — | — | 0.1 ° API | Glass | 15" | 15/16" | Built-In Thermometer | 0 to 150 | ASTM E2995 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Salt Water (Sodium Chloride) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Saturation | — | — | 0% to 100% | — | 1% | Glass | 12" | 11/16" | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Salt Water (Calcium Chloride) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specific Gravity | — | 1 to 1.28 | — | — | 0.002 | Glass | 12" | 3/4" | — | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Sugar Water (Sucrose) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brix (Sugar) | — | — | — | -5% to 5% | 0.1% | Glass | 13" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brix (Sugar) | — | — | — | -1% to 11% | 0.1% | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brix (Sugar) | — | — | — | 0% to 30% | 0.5% | Glass | 12" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brix (Sugar) | — | — | — | 9% to 21% | 0.1% | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brix (Sugar) | — | — | — | 19% to 31% | 0.1% | Glass | 14" | 15/16" | Built-In Thermometer | 32 to 120 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Battery Testing Density Meters

Easy-Read Concentration Meters

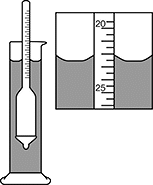

Density Meter Jars

Cap., ml | For Max. Density Meter Ht. | Dia. | Ht. | Mouth ID | Color | Max. Temp., ° F | Autoclavable | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Borosilicate Glass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 9" | 1 1/4" | 9 5/8" | 1 1/16" | Clear | 500 | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 12" | 1 5/8" | 12 9/16" | 1 1/2" | Clear | 500 | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 14" | 2 1/8" | 15" | 1 15/16" | Clear | 500 | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 700 | 15" | 1 15/16" | 15 3/4" | 1 3/4" | Clear | 500 | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 16" | 2 3/4" | 17 5/16" | 2 9/16" | Clear | 500 | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 17" | 2 1/2" | 18 1/8" | 2 3/8" | Clear | 500 | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Concentration Meters

Celsius Scale

Temp. Range, ° C | Graduations, ° C | ATC Range, ° C | Lg. | Material | Container Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Testing Freezing Point, For Testing Specific Gravity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -50 to 0 | 1 | 10 to 30 | 7" | Nickel-Plated Brass | Plastic | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fahrenheit Scale

Temp. Range, ° F | Graduations, ° F | ATC Range, ° F | Lg. | Material | Container Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Testing Freezing Point, For Testing Specific Gravity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -60 to 32 | 2 | 50 to 86 | 7" | Nickel-Plated Brass | Plastic | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

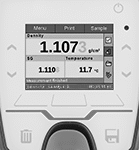

Digital Density Meters

Min. Sample Volume, ml | Measurement Unit | Lg. | Features | Density Range, g/cm³ | Accuracy | Temp. Range, ° F | Housing Material | Data Connection | Enclosure Rating | Hazardous Location Rating | Specs. Met | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Battery Acid, Heavy Liquids, Light Liquids, Salt Water (Sodium Chloride), Salt Water (Calcium Chloride), and Sugar Water (Sucrose) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Baume, Brix (Sugar), KMW, Oechsle, Specific Gravity, Plato | 9 5/8" | Memory Storage | 0 to 3 | ±0.04% | 32 to 100 | Rubber | Bluetooth, RFID | IP54 | IEC Zone 1 Groups IIB, IIA | ASTM D7777 | Adapter, Carrying Case, Filling Tube (180 mm), Measuring Cell, Pump Lever, Ten Syringes | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Density Testing Flasks

Mouth | Thermometer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Dia. | Ht. | ID | OD | Color | Max. Temp., ° F | Autoclavable | Includes | For Stem Lg. | Graduations, ° C | Temp. Measurement Range, ° C | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1 1/8" | 6 5/8" | 3/8" | 5/8" | Clear | 930 | Yes | Thermometer | 1 1/16" | 0.2 | 14 to 38 | — | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 1 5/8" | 6 7/8" | 3/8" | 5/8" | Clear | 930 | Yes | Thermometer | 1 1/16" | 0.2 | 14 to 38 | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 2 1/8" | 7 3/8" | 3/8" | 5/8" | Clear | 930 | Yes | Thermometer | 1 3/4" | 0.2 | 14 to 38 | ASTM D153 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||