About Shaft Couplings

More

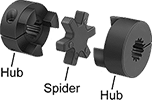

Splined Flexible Shaft Couplings

For use with splined shafts, which are commonly found in gearboxes and pumps, these couplings are capable of transmitting more torque than couplings for round and keyed shafts. They have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

A complete coupling consists of two hubs and one spider (each component sold separately). Hubs fasten onto your shafts without damaging them. Tighten the clamping screws to secure.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance. Polyurethane spiders provide fair vibration damping and good chemical resistance.

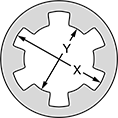

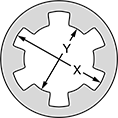

Dia. | ||

|---|---|---|

| SAE Spline Size | (X) | (Y) |

| A | 5/8" | 0.509" |

| B | 7/8" | 0.754" |

| B-B | 1" | 0.877" |

| C | 1 1/4" | 1.087" |

| D | 1 3/4" | 1.506" |

| E | 1 3/4" | 1.506" |

Buna-N Rubber Spiders | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | For Motion Type | Choose an SAE Spline Size | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 2 3/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 9,000 | 140 | 0.015" | 1° | -40° to 212° | 0000000 | 000000 | |

| 2 9/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 9,000 | 140 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | |

| 2 7/8" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 7,000 | 315 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | |

| 3 1/2" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 7,000 | 315 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | |

| 4 1/4" | 3 21/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 5,000 | 790 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | |

| 4 1/2" | 3 3/4" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 5,000 | 1,240 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | |

Hytrel Rubber Spiders | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | For Motion Type | Choose an SAE Spline Size | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 2 3/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 400 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | |

| 2 9/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 400 | 0.015" | 0.5° | -55° to 245° | 0000000 | 00000 | |

| 2 7/8" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 790 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | |

| 3 1/2" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 790 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | |

| 4 1/4" | 3 21/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 2,265 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | |

| 4 1/2" | 3 3/4" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 3,705 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | |

Polyurethane Spiders | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Iron Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | For Motion Type | Choose an SAE Spline Size | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 2 3/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 210 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 | |

| 2 9/16" | 2 7/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 210 | 0.015" | 1° | -30° to 160° | 0000000 | 00000 | |

| 2 7/8" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 475 | 0.015" | 1° | -30° to 160° | 0000000 | 00000 | |

| 3 1/2" | 2 17/32" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 00000 | 3,600 | 475 | 0.015" | 1° | -30° to 160° | 0000000 | 00000 | |

| 4 1/4" | 3 21/64" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 1,185 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 | |

| 4 1/2" | 3 3/4" | 0.5" | 30° | Forward/Reverse, Start/Stop, Continuous | 000000 | 000000 | 3,600 | 1,860 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 | |

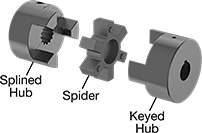

Splined-to-Keyed Flexible Shaft Couplings

Connect splined shafts to keyed shafts. These couplings are commonly used to connect hydraulic pumps, compressors, and other heavy duty equipment, which often have splined shafts, to electric motors and other components that often have keyed shafts. They have a splined hub on one side and a keyed hub on the other. A spider cushion in the middle damps vibration, absorbs shock loads, and adjusts for misalignment. Because the hubs interlock with the spider, these couplings will continue to work even if the spider breaks or wears away. This fail-safe design gives you time to shut down your power source before damage occurs to other components. Lubrication is not required.

A complete coupling consists of two hubs and one spider. All components are sold separately.

Buna-N spiders are best for high-speed systems and jobs with frequent starting, stopping, and reversing. The most commonly used spider material, Buna-N absorbs vibration better than other materials but cannot handle as much torque. It won't break down when exposed to oil and chemicals.

Use polyurethane spiders for high-torque, continuous-motion applications where vibration is a concern. They absorb vibration better than Hytrel spiders but are not as resistant to oil and chemicals. They're not for use in applications with frequent starting, stopping, and reversing.

Hytrel spiders handle the highest torque of any of our spiders and have the best resistance to oil and chemicals. However, they don't compensate for as much misalignment and are not recommended for applications with frequent starting, stopping, and reversing.

Dia. | ||

|---|---|---|

| SAE Spline Size | (X) | (Y) |

| A | 5/8" | 0.509" |

| B | 7/8" | 0.754" |

| B-B | 1" | 0.877" |

| C | 1 1/4" | 1.087" |

| D | 1 3/4" | 1.506" |

| E | 1 3/4" | 1.506" |

Buna-N Rubber Spiders | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Splined Iron Hubs | Keyed Iron Hubs | Misalignment Capability | ||||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | Choose an SAE Spline Size | Each | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | |||

| 2 3/16" | 2 7/64" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 000000 | 9,000 | 140 | 0.015" | 1° | -40° to 212° | 0000000 | 000000 | ||

| 2 7/8" | 2 17/32" | 0.5" | 30° | 00000000 | 00000 | 00000000 | 00000 | 7,000 | 315 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | ||

| 4 1/2" | 3 3/4" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 00000 | 5,000 | 1,240 | 0.015" | 1° | -40° to 212° | 0000000 | 00000 | ||

Polyurethane Spiders | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Splined Iron Hubs | Keyed Iron Hubs | Misalignment Capability | ||||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | Choose an SAE Spline Size | Each | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | |||

| 2 3/16" | 2 7/64" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 000000 | 3,600 | 210 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 | ||

| 2 7/8" | 2 17/32" | 0.5" | 30° | 00000000 | 00000 | 00000000 | 00000 | 3,600 | 475 | 0.015" | 1° | -30° to 160° | 0000000 | 00000 | ||

| 4 1/2" | 3 3/4" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 00000 | 3,600 | 1,860 | 0.015" | 1° | -30° to 160° | 0000000 | 000000 | ||

Hytrel Rubber Spiders | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Splined Iron Hubs | Keyed Iron Hubs | Misalignment Capability | ||||||||||||||

| O'all Lg. | OD | Pitch | Pressure Angle | Choose an SAE Spline Size | Each | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | |||

| 2 3/16" | 2 7/64" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 000000 | 3,600 | 400 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | ||

| 2 7/8" | 2 17/32" | 0.5" | 30° | 00000000 | 00000 | 00000000 | 00000 | 3,600 | 790 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | ||

| 4 1/2" | 3 3/4" | 0.5" | 30° | 00000000 | 000000 | 00000000 | 00000 | 3,600 | 3,705 | 0.015" | 0.5° | -55° to 245° | 0000000 | 000000 | ||