Filter by

Handle Material

Length

Sold As

Pin Diameter

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Overall Length

Container Type

Performance

Starrett Spring-Impact Center Punches

Steel Handle | Aluminum Handle | Aluminum Handle with Self-Centering Sleeve |

Point Dia. | Lg. | Mfr. Model No. | Punch Material | Handle Shape | Grip Texture | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" | 5 1/4" | 18C | Steel | Round | Knurled | — | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 4" | 18AA | Steel | Round | Knurled | — | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 5" | 18A | Steel | Round | Knurled | — | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" | 5" | 818 | Steel | Round | Knurled | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" | 5" | 819 | Steel | Round | Knurled | Self-Centering Sleeve | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring-Impact Center Punches

Steel Handle | Stainless Steel Handle |

Aluminum Handle | Plastic and Rubber Handle |

Punches | Replacement Center Punch Points | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Point Dia. | Lg. | Punch Material | Handle Shape | Grip Texture | Features | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 5 1/8" | Steel | Round | Knurled | — | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 5 5/8" | Steel | Round | Knurled | — | 0000000 | 00000 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 5 1/8" | Steel | Round | Knurled | — | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 5 3/4" | Steel | Round | Knurled | Pocket Clip | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5" | Steel | Round | Knurled | — | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic and Rubber Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 8 5/8" | Steel | Round | Ribbed | Ergonomic Design | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Center-Locating Punches for Curved Surfaces

Punch Operation | Angle Measured Range | Graduations | Angle Numeric Increments | For Min. Pipe OD | Material | Punch Material | Includes | Features | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spring Loaded | 0° to 90° | 2.5° | 10° | 1" | Aluminum | Steel | Adjustable Dial Protractor | Bubble Level | 000000 | 0000000 | ||

Impact-Resistant Pin Removal Punch Sets for Hollow and Spring Pins

Handle | |||||||||

|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Includes | Shape | Texture | Material | Container Type | Tip Shape | Each | ||

| 7 | Punch for 1/16", 1.5 mm Pin Dia. (3 3/4" O'all Lg.) Punch for 3/32", 2.5 mm Pin Dia. (4 1/4" O'all Lg.) Punch for 1/8", 3 mm Pin Dia. (4 3/4" O'all Lg.) Punch for 5/32", 4 mm Pin Dia. (5 1/4" O'all Lg.) Punch for 3/16", 5 mm Pin Dia. (5 7/16" O'all Lg.) Punch for 7/32", 5.5 mm Pin Dia. (5 7/8" O'all Lg.) Punch for 1/4", 6 mm Pin Dia. (6 7/16" O'all Lg.) | Hex | Smooth | Steel | Pouch | Round | 000000000 | 000000 | |

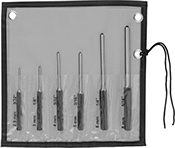

Pin Insertion Tool Sets for Hollow and Spring Pins

|

No. of Pieces | Includes | Each | ||

|---|---|---|---|---|

| 5 | 1/16" (1.6 mm) Pin Dia. Tool (4" O'all Lg.) 5/64" (2 mm) Pin Dia. Tool (4 1/4" O'all Lg.) 3/32" (2.4 mm) Pin Dia. Tool (4 1/2" O'all Lg.) 1/8" (3.2 mm) Pin Dia. Tool (4 3/4" O'all Lg.) 9/64" (3.5 mm) Pin Dia. Tool (5" O'all Lg.) | 0000000 | 000000 |

Pin Removal Punch Sets for Hollow and Spring Pins

Handle | ||||||||

|---|---|---|---|---|---|---|---|---|

No. of Pieces | Includes | Shape | Texture | Material | Container Type | Each | ||

| 6 | Punch for 1/8" (3 mm) Pin Dia. (4" O'all Lg.) Punch for 9/64" (3.5 mm) Pin Dia. (4" O'all Lg.) Punch for 5/32" (4 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 3/16" (5 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 1/4" (6 mm) Pin Dia. (5 1/2" O'all Lg.) Punch for 5/16" (8 mm) Pin Dia. (6" O'all Lg.) | Round | Knurled | Steel | Pouch | 000000 | 000000 | |

| 6 | Punch for 3/32" (2 mm) Pin Dia. (3 1/2" O'all Lg.) Punch for 1/8" (3 mm) Pin Dia. (3 3/4" O'all Lg.) Punch for 5/32" (4 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 3/16" (5 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 1/4" (6 mm) Pin Dia. (5 1/2" O'all Lg.) Punch for 5/16" (8 mm) Pin Dia. (6" O'all Lg.) | Hex | Smooth | Steel | Pouch | 0000000 | 00000 | |

| 6 | Punch for 1/8" (3 mm) Pin Dia. ( 5 1/2" O'all Lg.) Punch for 5/32" (4 mm) Pin Dia. ( 6 1/4" O'all Lg.) Punch for 3/16" (5 mm) Pin Dia. ( 6 1/2" O'all Lg.) Punch for 7/32" (5.5 mm) Pin Dia. (6 3/4" O'all Lg.) Punch for 1/4" (6 mm) Pin Dia. (7 1/4" O'all Lg.) Punch for 5/16" (8 mm) Pin Dia. (7 3/4" O'all Lg.) | Hex | Smooth | Steel | Plastic Caddy | 0000000 | 00000 | |

| 9 | Punch for 1/16" (1.5 mm) Pin Dia. (4 1/4" O'all Lg.) Punch for 5/64" (1.9 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 3/32" (2 mm) Pin Dia. (4 3/4" O'all Lg.) Punch for 1/8" (3 mm) Pin Dia. ( 5 1/2" O'all Lg.) Punch for 5/32" (4 mm) Pin Dia. ( 6 1/4" O'all Lg.) Punch for 3/16" (5 mm) Pin Dia. ( 6 1/2" O'all Lg.) Punch for 7/32" (5.5 mm) Pin Dia. (6 3/4" O'all Lg.) Punch for 1/4" (6 mm) Pin Dia. (7 1/4" O'all Lg.) Punch for 5/16" (8 mm) Pin Dia. (7 3/4" O'all Lg.) | Hex | Smooth | Steel | Pouch | 0000000 | 00000 | |

| 12 | Punch for 1/16" (1.5 mm) Pin Dia. (4 1/4" O'all Lg.) Punch for 5/64" (1.9 mm) Pin Dia. (4 1/2" O'all Lg.) Punch for 3/32" (2 mm) Pin Dia. (4 3/4" O'all Lg.) Punch for 1/8" (3 mm) Pin Dia. ( 5 1/2" O'all Lg.) Punch for 5/32" (4 mm) Pin Dia. ( 6 1/4" O'all Lg.) Punch for 3/16" (5 mm) Pin Dia. ( 6 1/2" O'all Lg.) Punch for 7/32" (5.5 mm) Pin Dia. (6 3/4" O'all Lg.) Punch for 1/4" (6 mm) Pin Dia. (7 1/4" O'all Lg.) Punch for 5/16" (8 mm) Pin Dia. (7 3/4" O'all Lg.) Punch for 3/8" (10 mm) Pin Dia. (8" O'all Lg.) Punch for 7/16" (11 mm) Pin Dia. (8 1/2" O'all Lg.) Punch for 1/2" (12.5 mm) Pin Dia. (9 1/4" O'all Lg.) | Hex | Smooth | Steel | Plastic Caddy | 0000000 | 00000 | |

Impact-Resistant Pin Removal Punches for Hollow and Spring Pins

For Pin | Handle | ||||||||

|---|---|---|---|---|---|---|---|---|---|

Dia. | Lg. | Overall Lg. | Shape | Texture | Material | Each | |||

| 1/16", 1.5 mm | 31/32" | 3 3/4" | Hex | Smooth | Steel | 0000000 | 00000 | ||

| 3/32", 2.5 mm | 1 7/16" | 4 1/4" | Hex | Smooth | Steel | 0000000 | 0000 | ||

| 1/8", 3 mm | 2 1/32" | 4 3/4" | Hex | Smooth | Steel | 0000000 | 0000 | ||

| 5/32", 4 mm | 2 1/2" | 5 1/4" | Hex | Smooth | Steel | 0000000 | 00000 | ||

| 3/16", 5 mm | 2 1/2" | 5 7/16" | Hex | Smooth | Steel | 0000000 | 00000 | ||

| 7/32", 5.5 mm | 2 15/16" | 5 7/8" | Hex | Smooth | Steel | 0000000 | 00000 | ||

| 1/4", 6 mm | 3 7/16" | 6 7/16" | Hex | Smooth | Steel | 0000000 | 00000 | ||

Pin Removal Punches for Hollow and Spring Pins

| |

Round Tip |

For Pin | Handle | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Lg. | Overall Lg. | Shape | Texture | Material | Tip Shape | Each | |||

| 1/16", 1.5 mm | 1" | 4 1/4" | Hex | Smooth | Steel | Round | 0000000 | 00000 | ||

| 5/64", 2 mm | 1 1/4" | 4 1/2" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 3/32", 2.5 mm | 1 1/2" | 4 3/4" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 1/8", 3 mm | 2" | 5 1/2" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 5/32", 4 mm | 2 3/4" | 6 1/4" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 3/16", 5 mm | 3" | 6 1/2" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 7/32", 5.5 mm | 3" | 6 3/4" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 1/4", 6 mm | 3 3/4" | 7 1/4" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 5/16", 8 mm | 3 3/4" | 7 3/4" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 3/8", 9.5 mm | 4 1/4" | 8" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 7/16", 11 mm | 4 1/4" | 8 1/2" | Hex | Smooth | Steel | Round | 0000000 | 0000 | ||

| 1/2", 13 mm | 5" | 9 1/4" | Hex | Smooth | Steel | Round | 0000000 | 00000 | ||