Extra-Stretch Extension Springs

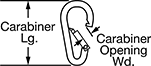

These fabric-covered rubber springs stretch up to three times their original length—much farther than traditional extension springs, tie downs, and shock cords. All have carabiner ends with spring-loaded latch openings. Do not use to hold overhead loads.

As you stretch an extension spring, it gets harder to pull. Minimum load is the amount of force required to start to extend the spring. Maximum load is the amount of force required to fully extend the spring. Spring rate is the amount of force required for every inch of extension.

Load, lbs. | Carabiner | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Extended Lg. @ Max. Load | Min. | Max. | Spring Rate, lbs./in. | Material | Sleeve Material | Lg. | Opening Wd. | Material | Temperature Range, °F | Each | |

24" Lg. | ||||||||||||

| 1" | 60" | Not Rated | 33 | 0.92 | Latex Rubber | Polypropylene Fabric | 2" | 5/16" | Black-Oxide Steel | 30° to 130° | 0000000 | 000000 |

| 1.75" | 60" | Not Rated | 47 | 1.31 | Latex Rubber | Polypropylene Fabric | 2" | 5/16" | Black-Oxide Steel | 30° to 130° | 0000000 | 00000 |

| 1.75" | 60" | Not Rated | 77 | 2.14 | Latex Rubber | Polypropylene Fabric | 2" | 5/16" | Black-Oxide Steel | 30° to 130° | 0000000 | 00000 |

Wear-Resistant 1095 Spring Steel Sheets and Strips

- Yield Strength: Not Rated

- Hardness: Rockwell C48-C51 (Very Hard)

- Fabrication: Cold Worked

- Specifications Met: ASTM A684

Also known as blue-tempered steel, this 1095 spring steel has a higher carbon content than 1075 spring steel for better wear resistance. It’s often used for spring clips, washers, and other parts that are under continual stress. These sheets and strips are hardened for increased abrasion and impact resistance. All meet ASTM A684 standards for performance and quality.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Wd. | Lg., ft. | Thick. Tolerance | Heat Treatment | Mechanical Finish | Color | Each | |

0.004" Thick. | |||||||

|---|---|---|---|---|---|---|---|

| 6" | 2 | -0.0004" to 0.0004" | Hardened | Polished | Blue | 00000000 | 000000 |

0.005" Thick. | |||||||

| 6" | 2 | -0.0005" to 0.0005" | Hardened | Polished | Blue | 00000000 | 00000 |

0.008" Thick. | |||||||

| 6" | 2 | -0.0008" to 0.0008" | Hardened | Polished | Blue | 00000000 | 00000 |

0.01" Thick. | |||||||

| 12 3/8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 0000000 | 00000 |

0.015" Thick. | |||||||

| 8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 10" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 0000000 | 00000 |

0.02" Thick. | |||||||

| 8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 10" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 0000000 | 00000 |

0.025" Thick. | |||||||

| 6" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 10" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 0000000 | 00000 |

0.028" Thick. | |||||||

| 6" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

| 8" | 2 | -0.001" to 0.001" | Hardened | Polished | Blue | 00000000 | 00000 |

0.03" Thick. | |||||||

| 6" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

0.032" Thick. | |||||||

| 6" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 10" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 0000000 | 00000 |

0.035" Thick. | |||||||

| 6" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 0000000 | 00000 |

0.042" Thick. | |||||||

| 4" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 6" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 0000000 | 00000 |

0.05" Thick. | |||||||

| 3" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 4" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 0000000 | 00000 |

| 24" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 000000 |

0.062" Thick. | |||||||

| 2 1/2" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 3" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 00000000 | 00000 |

| 12 3/8" | 2 | -0.002" to 0.002" | Hardened | Polished | Blue | 0000000 | 00000 |

Easy-to-Form Wear-Resistant 1095 Spring Steel Sheets

- Yield Strength: Not Rated

- Hardness: Rockwell B90 (Medium)

- Fabrication: See table

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Specifications Met: See table

These sheets are annealed to soften their temper, so they can be formed into shape and then heat treated for spring properties. They’re made from 1095 spring steel, which is more wear resistant than 1075 spring steel because of its higher carbon content. These sheets are often made into parts that will be used under continual stress, such as spring clips and washers. They have been manufactured to ASTM standards for quality and performance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Thick. | Thick. Tolerance | Fabrication | Heat Treatment | Specifications Met | Flatness Tolerance | Each | |

8" × 24" | |||||||

|---|---|---|---|---|---|---|---|

| 0.015" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 000000 |

| 0.02" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.025" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.032" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.035" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.042" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.05" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.062" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.072" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.078" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.083" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.094" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.109" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 1/8" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 00000 |

| 0.134" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.156" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.187" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 0000000 | 000000 |

24" × 24" | |||||||

| 0.015" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.02" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.025" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.032" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.035" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.042" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.05" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.062" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.065" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.072" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.078" | -0.002" to 0.002" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.094" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.109" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 1/8" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 00000 |

| 0.134" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 000000 |

| 0.156" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 000000 |

| 0.187" | -0.003" to 0.003" | Cold Worked | Annealed (Softened) | ASTM A684 | 3/8" | 00000000 | 000000 |

1075 Spring Steel Strips

- Yield Strength: Not Rated

- Hardness: Rockwell C45 (Hard)

1075 spring steel is easier to bend than 1095, but it has less bounce-back after heat treating. It is often used for springs and shims. This material is also known as scaleless steel.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Easy-to-Form 1075 Spring Steel Sheets

- Yield Strength: 50,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C64

- Specifications Met: ASTM A684

These sheets have a softened temper, which is also known as annealed, so they can be easily formed into shape and then heat treated for spring properties. 1075 spring steel is easier to bend than 1095, but it has less bounce-back after heat treating. It is often used for springs and shims.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

8" × 24" | |||||

|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Heat Treatment | Flatness Tolerance | Each | |

| 0.015" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 000000 |

| 0.02" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.025" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.032" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.035" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.042" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.05" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.062" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.072" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.083" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.094" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.109" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.125" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 00000 |

| 0.187" | -0.003" to 0.003" | Annealed (Softened) | 3/8" | 0000000 | 000000 |

Easy-To-Form Multipurpose 1050 Spring Steel Sheets

- Yield Strength: 38,000 psi

- Hardness: Rockwell B74

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Rockwell C58

- Specifications Met: ASTM A682, ASTM A684

Containing more carbon than low-carbon steel—but less than 1095 spring steel—1050 spring steel is easily formed into parts such as washers, brackets, and springs before being hardened for use. It resists stress, so it won’t snap when formed or twisted. Because it has a lower carbon content than 1095 spring steel, it’s not as wear resistant.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

8" × 24" | |||||

|---|---|---|---|---|---|

| Thickness | Thickness Tolerance | Heat Treatment | Flatness Tolerance | Each | |

| 0.025" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 000000 |

| 0.032" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.035" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.042" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.05" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.062" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.072" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.083" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 00000 |

| 0.094" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 0000000 | 000000 |

| 0.109" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 00000000 | 000000 |

| 1/8" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 00000000 | 000000 |

| 0.187" | -0.003" to 0.003" | Annealed (Softened) | Not Rated | 00000000 | 000000 |

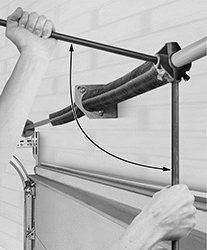

Winding Rods for Overhead Door Springs

Keep your overhead door balanced on both tracks for smooth, even opening and closing. These winding rods help you safely increase and decrease the tension on the springs that hold the door. Their ends are machined to fit snugly into the springs' tensioning holes, giving you good control and preventing these rods from slipping out as you tension. Use these rods in pairs. For better leverage and easier winding, choose longer rods.

Step | ||||||

|---|---|---|---|---|---|---|

| Dia. | Lg. | Dia. | Lg. | Material | Pair | |

| 5/8" | 24" | 1/2" | 1 1/4" | Steel | 0000000 | 000000 |