Filter by

Number of Teeth

Shaft Diameter

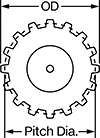

OD

Hub Diameter

Strand Type

Chain Type

Overall Width

Width

Component

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Bearing Type

Sprockets

|

For Single Strand |

For Roller Chain | Keyway | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

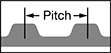

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Wd. | Dp. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 10 | 15/16" | Finished | 1/4" | — | — | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 10 | 15/16" | Plain | 1/4" | — | — | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 3/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Plain | 3/8" to 9/16" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Plain | 1/2" to 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Plain | 5/8" to 7/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Plain | 3/4" to 1 1/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Plain | 1" to 1 1/2" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 10 | 4 5/8" | Finished | 1" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 10 | 4 5/8" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 10 | 4 5/8" | Finished | 1 3/8" | 5/16" | 5/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | ANSI | 1 1/4" | 10 | 4 5/8" | Plain | 1" to 1 7/8" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | ANSI | 1 1/2" | 10 | 5 1/2" | Plain | 1 3/8" to 2 1/4" | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | ANSI | 2" | 10 | 7 3/8" | Plain | 1 1/2" to 2 3/4" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 04B | ISO | 6 mm | 10 | 22 mm | Plain | 6 mm to 8 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 05B | ISO | 8 mm | 10 | 29 mm | Plain | 8 mm to 11 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 06B | ISO | 3/8" | 10 | 34 mm | Plain | 8 mm to 12 mm | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 08B | ISO | 1/2" | 10 | 47 mm | Plain | 10 mm to 20 mm | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10B | ISO | 5/8" | 10 | 61 mm | Plain | 12 mm to 22 mm | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wear-Resistant Steel with Hardened Teeth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 3/8" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 1/2" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 10 | 2 3/4" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 1/8" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 3/16" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | ANSI | 1" | 10 | 3 11/16" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.1475" | 10 | 1/2" | Finished | 1/8" | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 10 | 15/16" | Plain | 1/4" | — | — | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 3/8" | 3/32" | 3/64" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Finished | 1/2" | 1/8" | 1/16" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Plain | 3/8" to 9/16" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 1/2" | 1/8" | 1/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 5/8" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Plain | 1/2" to 3/4" | — | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Plain | 5/8" to 7/8" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Idler Sprockets

For Single Strand

|

Ball Bearing |

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | For Shaft Dia. | OD | Bearing Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | ANSI | 1 1/2" | 10 | 1" | 5 1/2" | Steel | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Sprockets

|

For Roller Chain | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.1227" | 10 | 7/16" | Plain | 1/8" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | ANSI | 1/4" | 10 | 15/16" | Plain | 1/4" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 10 | 1 3/8" | Plain | 3/8" to 7/16" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 10 | 1 13/16" | Plain | 1/2" | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 10 | 2 5/16" | Plain | 1/2" to 3/4" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sprockets for Clog-Resistant Flat-Edge Roller Chain

|

For Roller Chain Trade No. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 81X | 2.609" | 10 | 9" | Plain | 1 1/4" to 3 7/16" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Timing Belt Pulleys

For Max. Belt Wd. | Pitch | No. of Teeth | Bore Type | For Shaft Dia. | Pitch Dia. | No. of Flanges | Hub Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For MXL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.080" | 10 | Finished | 1/8" | 0.255" | 1 | Standard | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.080" | 10 | Finished | 1/8" | 0.255" | 1 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 mm | 0.080" | 10 | Finished | 3 mm | 6.5 mm | 1 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 0.080" | 10 | Finished | 3 mm | 6.5 mm | 1 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 mm | 0.080" | 10 | Finished | 3 mm | 6.5 mm | 1 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For XL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 3/16" | 0.637" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 1/4" | 0.637" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.200" | 10 | Finished | 3/16" | 0.637" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 3/16" | 0.637" | 2 | Flush | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 3/16" | 0.637" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 1/4" | 0.637" | 2 | Flush | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 6 mm | 0.64" | 2 | Flush | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 6 mm | 0.64" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For L Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.375" | 10 | Finished | 3/8" | 1.194" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.375" | 10 | Finished | 10 mm | 1.19" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conveyor Belt Drive Sprockets for Food and Beverage Cut-Resistant Belting

No. of Teeth | For Shaft Dia. | OD | Wd. | Material | Color | Temp. Range, ° F | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ammeraal Beltech MPB Series | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One Piece | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1.5" | 6.55" | 1.66" | Nylon | Gray | -40 to 245 | FDA Compliant 21 CFR 177.1500 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conveyor Belt Drive Sprockets

One Piece

For Belt Series No. | For Shaft Dia. | No. of Teeth | OD | Wd. | Material | Color | Temp. Range, ° F | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1701 | 0.85" | 10 | 6.37" | 1.67" | Nylon | Gray | 32 to 190 | 0000000 | 000000 |

Plastic Timing Belt Pulleys

For Max. Belt Wd. | Pitch | No. of Teeth | Bore Type | For Shaft Dia. | Pitch Dia. | No. of Flanges | Hub Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For MXL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polycarbonate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.080" | 10 | Plain | 3/32" | 0.255" | 1 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 0.080" | 10 | Plain | 3 mm | 6.5 mm | 1 | Standard | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 0.080" | 10 | Plain | 3 mm | 6.5 mm | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For XL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 3/16" | 0.637" | 2 | Standard | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 10 | Finished | 6 mm | 0.64" | 2 | Standard | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

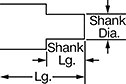

Timing Belt Pulley Stock

|  |  |

Shank End × Straight End |

Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | No. of Teeth | Pitch | Lg. | Lg. | Dia. | Pitch Dia. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For L Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.164" | 10 | 0.375" | 8" | 3/4" | 3/4" | 1.194" | Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Power Metal Helical Gears

Crossed Gears