About Roller Chain and Sprockets

More

Sprockets for ANSI Roller Chain

Mount these sprockets onto your shaft and secure with a set screw—no machining necessary.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

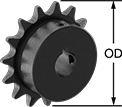

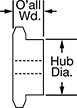

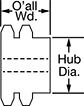

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 27 | 5/8" | 4.58" | 1" | 3 1/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 27 | 3/4" | 4.58" | 1" | 3 1/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 27 | 7/8" | 4.58" | 1" | 3 1/4" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 00000 |

| 27 | 1" | 4.58" | 1" | 3 1/4" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 00000 |

Sprockets for Metric Roller Chain

Designed to meet ISO 606 and DIN 8187 international dimensional standards, these sprockets are for use with compatible ISO and DIN roller chain. They come machined to the shaft diameter size listed and are machinable up to the maximum shaft diameter size.

Flat Sprockets for Metric Roller Chain

With metric teeth and slim profile, these sprockets allow your ISO roller chain to reach narrow spaces. They're commonly referred to as A-plate sprockets. Machine the unfinished bore to fit your shaft—sprockets come machined to the shaft diameter listed and are machinable up to the maximum shaft diameter size. Sprockets meet DIN 8187 and ISO 606, international standards for sprockets and roller chains.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Material | Specifications Met | Each | |

For ISO 08B Roller Chain (12.7 mm Pitch) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 27 | 16 | 96 | 116.33 | 8 | Steel | DIN 8187, ISO 606 | 00000000 | 000000 |

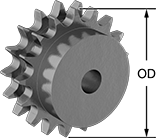

Sprockets for Double-Strand Metric Roller Chain

The double row of teeth on these sprockets are designed to fit into metric ISO double-strand roller chain. They have an unfinished bore that’s machined to the shaft diameter size listed. Machine them to fit any shaft up to the maximum shaft diameter size. The extended hub makes these sprockets more stable and more durable than flat sprockets. They meet ISO 606 (formerly DIN 8187), which is an international standard for sprocket and roller chain dimensions and materials.

| Number of Teeth | For Shaft Dia., mm | For Max. Shaft Dia., mm | OD, mm | Overall Wd., mm | Hub Dia., mm | Material | Specifications Met | Each | |

For ISO 06B-2 Roller Chain (9.53 mm Pitch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 27 | 12 | 45 | 87.6 | 30 | 70 | Steel | DIN 8187, ISO 606 | 00000000 | 0000000 |