Filter by

Number of Teeth

Roller Chain Trade Number

Component

Overall Width

Hub Diameter

Chain Type

Strand Type

Sprocket Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Sprockets

For Roller Chain | Keyway | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Wd. | Dp. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 3/4" | 3/16" | 3/32" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 7/8" | 3/16" | 3/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 1" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 1 1/4" | 1/4" | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 1 3/8" | 5/16" | 5/32" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 50 | 8 1/4" | Finished | 1 1/2" | 3/8" | 3/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

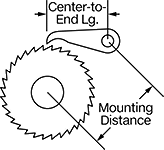

Metal Ratchet Gears and Pawls

Gears

Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face Wd., mm | No. of Teeth | OD, mm | For Shaft Dia., mm | Mounting Distance, mm | Material | Tooth Heat Treatment | Overall Wd., mm | Dia. | Wd. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 50 | 33.3 | 10 | 33.8 | 1045 Carbon Steel | Hardened | 6 | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 50 | 33.3 | 10 | 33.8 | 1045 Carbon Steel | Hardened | 16 | 25 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 50 | 50 | 12 | 45.5 | 1045 Carbon Steel | Hardened | 12 | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 50 | 50 | 12 | 45.5 | 1045 Carbon Steel | Hardened | 24 | 35 | 12 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 50 | 150 | 20 | 95.5 | 1045 Carbon Steel | Hardened | 20 | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 50 | 200 | 20 | 122.4 | 1045 Carbon Steel | Hardened | 43 | 100 | 18 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Worm Gears

Gears

Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Speed Ratio | No. of Teeth | Pressure Angle | Gear Pitch Dia., mm | For No. of Thread Starts | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Fabrication | Color | Dia. | Wd. | For Thread Direction | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | Molded | White | 20 | 7 | Right Hand | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 50:1 | 50 | 20° | 40 | 1 | 41.6 | 9 | 18 | 8 | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50:1 | 50 | 20° | 50 | 1 | 53 | 10 | 20 | 8 | Molded | Blue | 30 | 10 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

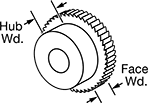

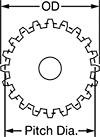

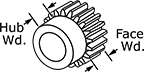

Metal Spur Gears

Gears

Hub | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Pitch | Gear Module | No. of Teeth | Gear Pitch Dia. | OD | Face Wd. | Dia. | Wd. | Bore Type | For Shaft Dia. | Tooth Heat Treatment | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20° Pressure Angle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 50 | 2 1/2" | 2.6" | 1/2" | 1.62" | 0.5" | Round Bore | 1/2" | Not Hardened | 1117 Carbon Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 50 | 25 mm | 26 mm | 5 mm | 22 mm | 7 mm | Round Bore with Set Screw | 5 mm | Not Hardened | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.8 | 50 | 40 mm | 41.6 mm | 8 mm | 28 mm | 8 mm | Round Bore with Set Screw | 6 mm | Not Hardened | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 50 | 50 mm | 52 mm | 10 mm | 35 mm | 10 mm | Round Bore with Set Screw | 8 mm | Not Hardened | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 50 | 75 mm | 78 mm | 15 mm | 50 mm | 10 mm | Round Bore | 12 mm | Not Hardened | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 50 | 100 mm | 104 mm | 20 mm | 55 mm | 10 mm | Round Bore | 15 mm | Not Hardened | Black-Oxide 1045 Carbon Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 50 | 25 mm | 26 mm | 5 mm | 17 mm | 10 mm | Clamping Bore with Clamping Screw | 6 mm | Not Hardened | 303 Stainless Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 50 | 50 mm | 52 mm | 10 mm | 35 mm | 10 mm | Round Bore | 10 mm | Not Hardened | 303 Stainless Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 50 | 25 mm | 26 mm | 3 mm | 22 mm | 7 mm | Round Bore with Set Screw | 4 mm | — | Brass | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.8 | 50 | 40 mm | 41.6 mm | 4 mm | 28 mm | 8 mm | Round Bore with Set Screw | 6 mm | — | Brass | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 50 | 50 mm | 52 mm | 6 mm | 28 mm | 8 mm | Round Bore with Set Screw | 8 mm | — | Brass | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

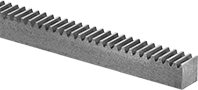

Gear Racks

Gear Pitch | Gear Module | Lg. | Pitch Ht. | Ht. | Face Wd. | Dia., mm | Tooth Heat Treatment | Material | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

20° Pressure Angle—Rectangular | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 2 ft. | 0.45" | 1/2" | 1/2" | — | Not Hardened | 1018 Low-Carbon Steel | — | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 4 ft. | 0.45" | 1/2" | 1/2" | — | Not Hardened | 1215 Carbon Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 6 ft. | 0.45" | 1/2" | 1/2" | — | Not Hardened | 1215 Carbon Steel | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 100 mm | 11.5 mm | 12 mm | 5 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 300 mm | 11.5 mm | 12 mm | 5 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | Machined Ends | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.8 | 100 mm | 11.5 mm | 12.3 mm | 8 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 100 mm | 11 mm | 12 mm | 10 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 300 mm | 11 mm | 12 mm | 10 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 500 mm | 8.8 mm | 9.8 mm | 10 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 1,000 mm | 8.8 mm | 9.8 mm | 10 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 100 mm | 18.5 mm | 20 mm | 15 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 300 mm | 18.5 mm | 20 mm | 15 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 500 mm | 13.3 mm | 14.8 mm | 15 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 1,000 mm | 13.3 mm | 14.8 mm | 15 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 1,000 mm | 13.5 mm | 15 mm | 15 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | Machined Ends | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 100 mm | 23 mm | 25 mm | 20 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 300 mm | 23 mm | 25 mm | 20 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 500 mm | 17.8 mm | 19.8 mm | 20 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 1,000 mm | 17.8 mm | 19.8 mm | 20 mm | — | Not Hardened | 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 1,000 mm | 18 mm | 20 mm | 20 mm | — | Not Hardened | Black-Oxide 1045 Carbon Steel | Machined Ends | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 500 mm | 11 mm | 12 mm | 10 mm | — | Hardened | 304 Stainless Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | 300 mm | 8.5 mm | 9 mm | 3 mm | — | — | Brass | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.8 | 300 mm | 9.2 mm | 10 mm | 4 mm | — | — | Brass | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 300 mm | 9 mm | 10 mm | 6 mm | — | — | Brass | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20° Pressure Angle—Round | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | 500 mm | 9 mm | — | — | 10 | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.5 | 500 mm | 13.5 mm | — | — | 15 | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 2 | 1,000 mm | 18 mm | — | — | 20 | Not Hardened | Black-Oxide 1045 Carbon Steel | — | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Gears

Gear Module | No. of Teeth | Gear Pitch Dia., mm | OD, mm | ID, mm | Face Wd., mm | Tooth Heat Treatment | Finished Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

20° Pressure Angle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 60 | 30 | 50 | 29 | 5 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 100 | 50 | 70 | 49 | 5 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 60 | 60 | 90 | 58 | 10 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 100 | 100 | 130 | 98 | 10 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 100 | 150 | 190 | 147 | 15 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 100 | 200 | 250 | 196 | 20 | Not Hardened | Black-Oxide 1045 Carbon Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal Worms and Worm Gears

Gears

Hub | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Gear Pitch | Speed Ratio | No. of Teeth | Pressure Angle | Gear Pitch Dia. | For No. of Thread Starts | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Dia. | Wd. | Material | For Thread Direction | Tooth Heat Treatment | Tooth Mechanical Finish | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Cast Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.22" | 5/8" | 1.375" | 3/4" | 2" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.24" | 5/8" | 1.375" | 3/4" | 1.94" | 0.75" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 50:1 | 50 | 20° | 25 mm | 1 | 26 mm | 5 mm | 12 mm | 5 mm | 20 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision High-Torque GT Timing Belt Pulleys

Timing Belt Pulleys

|

Finished Bore |

|

For Max. Belt Wd. | Pitch | No. of Teeth | Bore Type | For Shaft Dia. | Pitch Dia. | Hub Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For XL Trade Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.200" | 50 | Finished | 3/8" | 3.183" | Standard | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

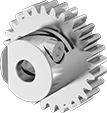

Plastic Spur Gears

Gears

Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | No. of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Dia. | Wd. | Bore Type | For Shaft Dia., mm | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20° Pressure Angle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 50 | 25 | 26 | 3 | 12 | 4 | Round Bore | 5 | White | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50 | 50 | 52 | 6 | 16 | 8 | Round Bore | 8 | White | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50 | 50 | 52 | 10 | 35 | 10 | Round Bore | 10 | Blue | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 50 | 75 | 78 | 15 | 45 | 10 | Round Bore | 10 | Blue | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gear Racks

|

20° Pressure Angle—Rectangular |