Filter by

Number of Teeth

Roller Chain Trade Number

Shaft Type

Component

System of Measurement

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Shaft Mount Type

Strand Type

Chain Standard

Sprocket Type

Gear Pitch

About Roller Chain and Sprockets

More

About Gears

More

Sprockets for ANSI Roller Chain

With Keyway

Mount these sprockets onto your shaft and secure with a set screw—no machining necessary.

For ANSI 40 Roller Chain (1/2" Pitch)

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

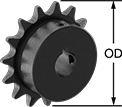

| Number of Teeth | For Shaft Dia. | OD | Overall Wd. | Hub Dia. | Wd. | Dp. | Material | Includes | Each | |

| 52 | 3/4" | 8.57" | 1 1/8" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 0000000 |

| 52 | 7/8" | 8.57" | 1 1/8" | 3 1/2" | 3/16" | 3/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 52 | 1" | 8.57" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 52 | 1 1/4" | 8.57" | 1 1/8" | 3 1/2" | 1/4" | 1/8" | Steel | Two Set Screws | 00000000 | 000000 |

| 52 | 1 3/8" | 8.57" | 1 1/8" | 3 1/2" | 5/16" | 5/32" | Steel | Two Set Screws | 00000000 | 000000 |

| 52 | 1 1/2" | 8.57" | 1 1/8" | 3 1/2" | 3/8" | 3/16" | Steel | Two Set Screws | 00000000 | 000000 |

Plastic Gears and Gear Racks—14 1/2° Pressure Angle

A former industry standard, 14½° pressure angle gears are often found on older machinery. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch.

Gears

Gear with Round or

Round/Machinable

Bore

Round/Machinable

Bore

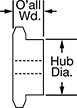

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Material | Fabrication | Color | Dia. | Wd. | Each | |

Round Bore | |||||||||||||

| 32 | 52 | 1 5/8" | 1.69" | 3/16" | 0.438" | 1/4" | Nylon Plastic | Molded | White | 0.625" | 0.25" | 00000000 | 000000 |