About Gears

More

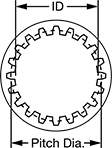

Metal Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Compared to plastic gears and racks, they’re better for high-load, high-speed, and heavy duty applications. Also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion. To minimize your footprint, mount one or more standard gears inside of an internal gear.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Brass gears and racks are easy to machine, so you can add your own mounting holes and make other alterations. They won't rust when exposed to water.

Gears with teeth that are not hardened can be hardened to fit your application.

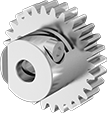

Stainless steel gears and racks resist rust in damp and wet environments, so they're commonly used in food-processing plants and other areas with frequent cleaning. Gears with a clamping bore have a built-in clamp that securely grips shafts without marring them. Use the included clamping screw to tighten or loosen the grip.

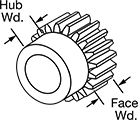

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Material | Teeth Heat Treatment | Dia. | Wd. | Set Screw Thread Size | Each | |

Round Bore with Set Screw | |||||||||||||

| 32 | 64 | 2" | 2.06" | 3/16" | 0.437" | 1/4" | 303 Stainless Steel | Not Hardened | 0.5" | 0.25" | 6-32 | 0000000 | 000000 |

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Material | Teeth Heat Treatment | Dia., mm | Wd., mm | Clamping Screw Thread Size | Each | |

Clamping Bore with Clamping Screw | |||||||||||||

| 1 | 64 | 64 | 66 | 6 | 20 | 10 | 303 Stainless Steel | Not Hardened | 24 | 14 | M4 | 0000000 | 0000000 |

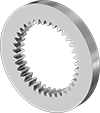

| Gear Pitch | Number of Teeth | Gear Pitch Dia. | OD | ID | Face Wd. | Material | Each | |

| 32 | 64 | 2" | 2.75" | 1.961" | 3/16" | Brass | 000000 | 0000000 |

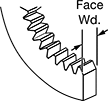

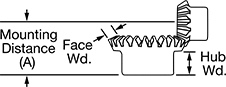

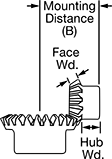

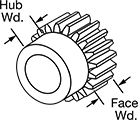

Metal Bevel Gears

A type of miter gear where one gear (sometimes called a pinion) is smaller than the other, bevel gears provide right-angle speed reduction at speed ratios ranging from 2:1 to 5:1. All are carbon steel for strength; they're compatible with plastic bevel gears. Teeth are not hardened so you can harden them to fit your application. Hardening a gear’s teeth increases its wear resistance.

A complete set consists of a gear and pinion (sold separately). For a gear and pinion to mesh correctly, they must have the same pressure angle, pitch/module, and face width. Speed ratio is the ratio by which shaft speed is reduced when transferring motion from pinion to gear. To increase shaft speed, transfer motion from gear to pinion. Changing shaft speed also changes torque: as speed decreases, torque increases.

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd. | Gear Pitch | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia. | OD | Overall Wd. | For Shaft Dia. | Mounting Distance (A) | Dia. | Wd. | Material | Each | |

Round Bore | ||||||||||||||

| 0.48" | 16 | 20° | 4:1 | 64 | 4" | 4.02" | 1.019" | 5/8" | 1.375" | 2.25" | 0.563" | 1144 Carbon Steel | 0000000 | 0000000 |

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Wd. | Gear Pitch | Pressure Angle | Speed Ratio | Number of Teeth | Gear Pitch Dia. | OD | Overall Wd. | For Shaft Dia. | Mounting Distance (B) | Dia. | Wd. | Material | Each | |

Round Bore | ||||||||||||||

| 0.48" | 16 | 20° | 4:1 | 16 | 1" | 1.17" | 0.984" | 1/2" | 2.5" | 0.813" | 0.476" | 1144 Carbon Steel | 0000000 | 000000 |

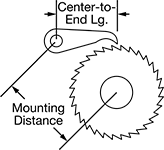

Plastic Gears and Gear Racks—14 1/2° Pressure Angle

A former industry standard, 14½° pressure angle gears are often found on older machinery. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch.

Round/Machinable

Bore

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Material | Fabrication | Color | Dia. | Wd. | Each | |

Round Bore | |||||||||||||

| 48 | 64 | 1.333" | 1.37" | 1/8" | 0.375" | 1/4" | Nylon Plastic | Molded | White | 0.625" | 0.25" | 00000000 | 000000 |

Plastic Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Acetal gears are best suited for use in light duty machines or for prototyping.

Hub | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Material | Fabrication | Color | Dia., mm | Wd., mm | Each | |

Round Bore | |||||||||||||

| 1 | 64 | 64 | 66 | 6 | 14 | 8 | Acetal Plastic | Molded | White | 18 | 8 | 00000000 | 000000 |

Metal Ratcheting Gears

Compared to plastic gears, these metal ratcheting gears are better for high-load, high-speed, and heavy duty applications. Used to prevent unwanted motion in jacks, tie downs, clutches, and winches, ratchet gears have sloped teeth that allow motion in one direction and prevent it in the other. Gears with teeth that are not hardened can be hardened to fit your application. Hardening a gear’s teeth increases its wear resistance.

| Face Wd. | Number of Teeth | OD | For Shaft Dia. | Mounting Distance | Material | Teeth Heat Treatment | Each | |

Round Bore | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/8" | 64 | 4" | 11/16" | 2.5" | 303 Stainless Steel | Not Hardened | 0000000 | 0000000 |