About Gears

More

MXL Series Lightweight Timing Belt Pulleys

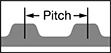

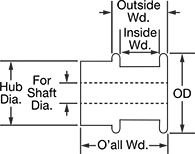

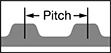

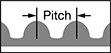

Made from polycarbonate, these pulleys are useful in applications with weight constraints. All are MXL series (miniature extra light) and have trapezoidal teeth. The teeth match up with the grooves along the inside diameter of a timing belt in order to move components forward or backward. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

2 Flanges | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

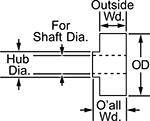

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Inside Wd. | Outside Wd. | Overall Wd. | Pitch Dia. | Fabrication | Material | Hub Dia. | Each | |

For 6 mm Max. Belt Wd. | |||||||||||||

| 63mm | 90 | 2.030mm | 8mm | Plain | 8mm | 11.2mm | 17.5mm | 58.2mm | Molded | Polycarbonate | 17.5mm | 0000000 | 000000 |

MXL Series Corrosion-Resistant Timing Belt Pulleys

Anodized aluminum has good corrosion resistance. Pulleys are MXL series (miniature extra light) and have trapezoidal teeth. The teeth match up with the grooves along the inside diameter of a timing belt in order to move components forward or backward. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

| OD | Number of Teeth | Pitch | For Shaft Dia. | Bore Type | Outside Wd. | Overall Wd. | Pitch Dia. | Fabrication | Material | Hub Dia. | Each | |

For 6 mm Max. Belt Wd. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 57.7mm | 90 | 2.030mm | 8mm | Finished | 9.5mm | 19.1mm | 58.2mm | Machined | Anodized Aluminum | 38.1mm | 00000000 | 000000 |

For 9 mm Max. Belt Wd. | ||||||||||||

| 57.7mm | 90 | 2.030mm | 8mm | Finished | 12.7mm | 22.2mm | 58.2mm | Machined | Anodized Aluminum | 38.1mm | 00000000 | 00000 |

High-Strength GT Timing Belt Pulleys

For higher speed or higher torque applications, these GT series timing belt pulleys provide a more precise fit than HTD pulleys. Use them where accuracy is critical, such as in storage and retrieval systems or in robotics. Similar to HTD timing belt pulleys, their teeth are curved for high strength. The curved teeth create positive grip engagement with timing belts, so these pulleys do not require re-tensioning—unlike drives using V-belts or sheaves. And unlike chain drives, there’s no metal-on-metal contact, so these pulleys don’t require lubrication.

Anodized aluminum pulleys are lightweight and resist corrosion. They have a finished bore and come with set screws for mounting on shafts.

| Number of Teeth | Pitch, mm | For Shaft Diameter | Bore Type | Outside Width, mm | Overall Width, mm | Pitch Diameter, mm | Fabrication | Material | Hub Diameter, mm | Each | |

For 9 mm Maximum Belt Width | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 90 | 3 | 5/16" | Finished | 12.7 | 22.26 | 85.954 | Machined | Anodized Aluminum | 31.75 | 00000000 | 000000 |

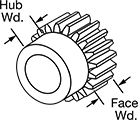

Metal Gears and Gear Racks—20° Pressure Angle

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Compared to plastic gears and racks, they’re better for high-load, high-speed, and heavy duty applications. Also known as spur gears.

Combine gears with different numbers of teeth to change speed and torque in your assembly. Combine a gear and rack to convert rotary motion into linear motion. To minimize your footprint, mount one or more standard gears inside of an internal gear.

For components to mesh correctly, they must have the same pressure angle and pitch/module.

Gears with teeth that are not hardened can be hardened to fit your application.

Stainless steel gears and racks resist rust in damp and wet environments, so they're commonly used in food-processing plants and other areas with frequent cleaning.

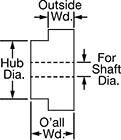

Hub | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Material | Teeth Heat Treatment | Dia., mm | Wd., mm | Each | |

Round Bore | ||||||||||||

| 1.5 | 90 | 135 | 138 | 15 | 29 | 15 | 303 Stainless Steel | Not Hardened | 80 | 14 | 00000000 | 0000000 |