Filter by

Roller Chain Trade Number

Strand Type

System of Measurement

Working Load

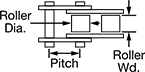

Roller Width

Roller Diameter

Roller Chain Type

Material

Chain Style

Chain Standard

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Chain Pitch Type