Filter by

Material

Thread Size

Face Style

OD

Width

Thread Spacing

Spanner Wrench Style

Specifications Met

Screw Size

RoHS

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

ID

Insert Maximum Temperature

Height

Thread Direction

For Lock Washer Specifications Met

Component

Performance

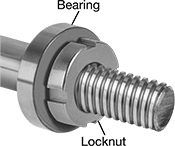

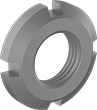

Bearing Locknuts

Locknuts | Sockets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | 303 Stainless Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Spacing | OD | Wd. | Insert Max. Temp., ° F | Specs. Met | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.391"-32 | Extra Fine | 3/4" | 9/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.469"-32 | Extra Fine | 7/8" | 3/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.586"-32 | Extra Fine | 1" | 3/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.664"-32 | Extra Fine | 1 1/8" | 13/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.781"-32 | Extra Fine | 1 3/8" | 13/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.969"-32 | Extra Fine | 1 9/16" | 15/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.173"-18 | Extra Fine | 1 3/4" | 15/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.312"-18 | Extra Fine | 2 1/16" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.376"-18 | Extra Fine | 2 1/16" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.563"-18 | Extra Fine | 2 1/4" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.767"-18 | Extra Fine | 2 17/32" | 1/2" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.967"-18 | Extra Fine | 2 11/16" | 9/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.157"-18 | Extra Fine | 2 31/32" | 9/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.360"-18 | Extra Fine | 3 5/32" | 19/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.548"-18 | Extra Fine | 3 3/8" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.751"-18 | Extra Fine | 3 5/8" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 21/32" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.137"-12 | Extra Fine | 4 5/32" | 5/8" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.918"-12 | Extra Fine | 5 3/16" | 13/16" | 160 | ANSI/ABMA 8.2 | 0000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 0.75 mm | Extra Fine | 18 mm | 7 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1 mm | Extra Fine | 22 mm | 8 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M15 × 1 mm | Extra Fine | 25 mm | 8.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M17 × 1 mm | Extra Fine | 28 mm | 9 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 1 mm | Extra Fine | 32 mm | 10 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 × 1 mm | Extra Fine | 34 mm | 10.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M25 × 1.5 mm | Extra Fine | 38 mm | 11 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 1.5 mm | Extra Fine | 42 mm | 11 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 1.5 mm | Extra Fine | 45 mm | 11.5 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 × 1.5 mm | Extra Fine | 48 mm | 11.5 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M35 × 1.5 mm | Extra Fine | 52 mm | 12 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 1.5 mm | Extra Fine | 58 mm | 12 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M45 × 1.5 mm | Extra Fine | 65 mm | 13 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M50 × 1.5 mm | Extra Fine | 70 mm | 13 mm | 160 | ISO 2982-2 | 0000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M55 × 2 mm | Extra Fine | 75 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M60 × 2 mm | Extra Fine | 80 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M65 × 2 mm | Extra Fine | 85 mm | 15 mm | 160 | ISO 2982-2 | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M70 × 2 mm | Extra Fine | 92 mm | 17 mm | 160 | ISO 2982-2 | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

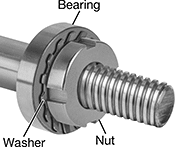

Bearing Nuts

Nuts | Bearing Lock Washers | Sockets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Spacing | OD | Wd. | Specs. Met | For Lock Washer Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.391"-32 | Extra Fine | 3/4" | 7/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.469"-32 | Extra Fine | 7/8" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.586"-32 | Extra Fine | 1" | 5/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.664"-32 | Extra Fine | 1 1/8" | 11/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.781"-32 | Extra Fine | 1 3/8" | 3/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.969"-32 | Extra Fine | 1 9/16" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 0000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.173"-18 | Extra Fine | 1 3/4" | 13/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.376"-18 | Extra Fine | 2 1/16" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.563"-18 | Extra Fine | 2 1/4" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.767"-18 | Extra Fine | 2 17/32" | 7/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.967"-18 | Extra Fine | 2 11/16" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.157"-18 | Extra Fine | 2 31/32" | 1/2" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.360"-18 | Extra Fine | 3 5/32" | 17/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 00000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.548"-18 | Extra Fine | 3 3/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.751"-18 | Extra Fine | 3 5/8" | 9/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 00000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.137"-12 | Extra Fine | 4 5/32" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.340"-12 | Extra Fine | 4 13/32" | 5/8" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.527"-12 | Extra Fine | 4 21/32" | 11/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.730"-12 | Extra Fine | 4 15/16" | 23/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.918"-12 | Extra Fine | 5 3/16" | 3/4" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.325"-12 | Extra Fine | 5 23/32" | 25/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.716"-12 | Extra Fine | 6 1/8" | 13/16" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 0000000 | 000000 | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

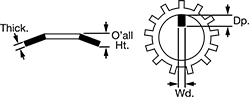

Bearing Spring Lock Washers for Slotted Bearing Nuts

Tab | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID | OD | Thk. | Wd. | Dp. | Overall Ht. | Tooth Location | Hardness | Specs. Met | For Bearing Nut Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Chamfered Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.875" | 0.046" | 0.120" | 0.063" | 0.125" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.484" | 1.106" | 0.046" | 0.120" | 0.064" | 0.148" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.601" | 1.156" | 0.046" | 0.120" | 0.066" | 0.172" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.679" | 1.328" | 0.046" | 0.120" | 0.067" | 0.195" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.801" | 1.531" | 0.046" | 0.176" | 0.062" | 0.203" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16" | 0.989" | 1.719" | 0.054" | 0.176" | 0.072" | 0.221" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1.193" | 1.922" | 0.054" | 0.176" | 0.093" | 0.213" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1.396" | 2.250" | 0.054" | 0.176" | 0.094" | 0.221" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.583" | 2.469" | 0.063" | 0.290" | 0.095" | 0.232" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1.792" | 2.734" | 0.063" | 0.290" | 0.096" | 0.224" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 1.992" | 2.922" | 0.063" | 0.290" | 0.097" | 0.239" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 2.182" | 3.109" | 0.068" | 0.290" | 0.103" | 0.225" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 2.400" | 3.344" | 0.068" | 0.290" | 0.124" | 0.249" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.588" | 3.578" | 0.068" | 0.290" | 1/8" | 0.256" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 2.791" | 3.828" | 0.068" | 0.290" | 1/8" | 0.256" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 2.973" | 4.109" | 0.077" | 0.290" | 0.135" | 0.274" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 3.177" | 4.375" | 0.077" | 0.353" | 0.132" | 0.267" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 3.395" | 4.625" | 0.077" | 0.353" | 0.133" | 0.298" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3.582" | 4.938" | 0.100" | 0.353" | 0.155" | 0.329" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 3.800" | 5.219" | 0.100" | 0.353" | 0.156" | 0.329" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/8" | 3.988" | 5.500" | 0.100" | 0.353" | 0.171" | 0.344" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/8" | 4.395" | 6.063" | 0.132" | 0.353" | 0.203" | 0.401" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 4.801" | 6.469" | 0.132" | 0.353" | 0.204" | 0.400" | External | Not Rated | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Ball Screws and Nuts

|  |  |  |  |

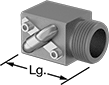

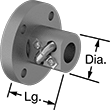

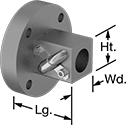

Ball Nuts, Externally Threaded Nut, Style A | Ball Nuts, Externally Threaded Nut, Style B | Ball Nuts Flange Nut Style C | Ball Nuts Flange Nut Style D |

Ball Screws—Right-Hand Threaded

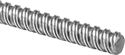

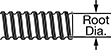

Thread Size | Lg., ft. | No. of Thread Starts | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Root Dia. | Hardness | Tensile Strength, psi | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 1 | 1 | 0.125" | ±0.005"/1 ft. | 0.3" | Rockwell C38 | 150,000 | -65 to 300 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 2 | 1 | 0.125" | ±0.004"/1 ft. | 0.3" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 4 | 1 | 0.125" | ±0.004"/1 ft. | 0.3" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 2 | 1 | 0.2" | ±0.004"/1 ft. | 0.5" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 4 | 1 | 0.2" | ±0.004"/1 ft. | 0.5" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 6 | 1 | 0.2" | ±0.004"/1 ft. | 0.5" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

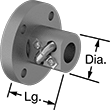

Externally Threaded Ball Nuts—Right-Hand Threaded

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-8 | 1" | — | — | 3/4" | 1 | 0.125" | 0.664"-32 | Rockwell C38 | 25 | 0.007" | -65 to 300 | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8"-5 | 1 23/32" | 1" | 1" | — | 1 | 0.2" | 15/16"-16 | Rockwell C38 | 170 | 0.007" | -65 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

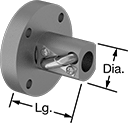

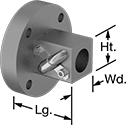

Flange Ball Nuts—Right-Hand Threaded

|  |  |

Style C | Style D |

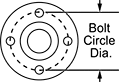

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Dia. | Thk. | No. of Thread Starts | Travel Distance per Turn | Bolt Circle Dia. | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/8"-8 | 1" | — | — | 3/4" | 1 19/32" | 17/64" | 1 | 0.125" | 1 15/64" | Rockwell C38 | 25 | 0.007" | -65 to 300 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 5/8"-5 | 1 47/64" | 1" | 1" | — | 2 19/32" | 17/32" | 1 | 0.2" | 2 3/32" | Rockwell C38 | 170 | 0.007" | -65 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fast-Travel Corrosion-Resistant Ball Screws and Nuts

Ball Screws—Right-Hand Threaded

Thread Size | Lg., ft. | No. of Thread Starts | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Root Dia. | Hardness | Tensile Strength, psi | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 1 | 2 | 0.5" | ±0.005"/1 ft. | 0.4" | Rockwell C38 | 150,000 | -65 to 300 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 2 | 2 | 0.5" | ±0.004"/1 ft. | 0.4" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 4 | 2 | 0.5" | ±0.004"/1 ft. | 0.4" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 6 | 2 | 0.5" | ±0.004"/1 ft. | 0.4" | Rockwell C38 | 145,000 | -65 to 300 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-4 | 3 | 2 | 0.5" | ±0.005"/1 ft. | 0.63" | Rockwell C38 | 150,000 | -65 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-4 | 6 | 2 | 0.5" | ±0.005"/1 ft. | 0.63" | Rockwell C38 | 150,000 | -65 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Ball Nuts—Right-Hand Threaded

Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 1 3/4" | 1 1/16" | 2 | 0.5" | 15/16"-16 | Rockwell C38 | 140 | 0.007" | -65 to 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-4 | 2 15/16" | 1 5/16" | 2 | 0.5" | 1 1/4"-16 | Rockwell C38 | 600 | 0.007" | -65 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange Ball Nuts—Right-Hand Threaded

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Dia. | Thk. | No. of Thread Starts | Travel Distance per Turn | Bolt Circle Dia. | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 1 29/32" | 1 1/16" | 2 19/32" | 17/32" | 2 | 0.5" | 2 3/32" | Rockwell C38 | 140 | 0.007" | -65 to 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-4 | 2 15/16" | 1 5/16" | 2 19/32" | 17/32" | 2 | 0.5" | 2 3/32" | Rockwell C38 | 600 | 0.007" | -65 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||