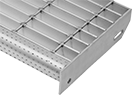

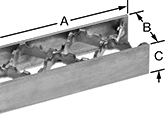

Metal Bar Grating Stair Treads

Choose these stair treads for greater durability than metal plank grating stair treads. They have an open surface that prevents debris from accumulating. Nosing is textured for traction.

Stainless steel treads have better corrosion resistance than steel or aluminum.

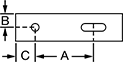

Drainage Opening | Mounting Hole | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Ht. | Thick. | Bearing Bar Ht. | Wd. | Lg. | Load Capacity, lbs. | No. of | Dia. | Lg. | Wd. | Ctr.-to-Ctr. (A) | Ctr.-to-Tread Top (B) | Ctr.-to-Tread Nosing (C) | Mounting Hardware Included | For Use Outdoors | Each | |

Smooth | ||||||||||||||||||

304 Stainless Steel | ||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 0000000 |

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

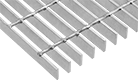

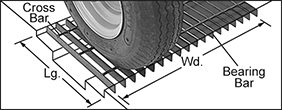

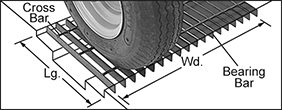

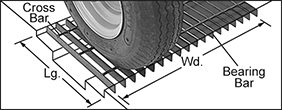

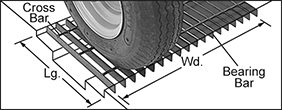

Metal Bar Grating

Able to support heavier loads than plank grating, bar grating is good for trenches, mezzanines, walkways, work platforms, and floors. This grating has an open design that allows air, light, and debris to flow through. Cross bars hold the bearing bars in place; bearing bars help distribute weight and must rest on supports. Use Fasteners for Metal Bar Grating to secure.

Serrated grating provides maximum slip resistance.

Stainless steel grating has better corrosion resistance than steel or aluminum.

To Order: For custom sizes, please specify width and length. Note: Grating less than 17" long is reinforced with banding.

Bearing Bar | Uniform Load | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd., ft. | Ht. | Wd. | Center-to-Center Wd. | Center-to-Center Cross Bar Lg. | Rating @ Unsupported Lg. | Deflection @ Unsupported Lg. | Mounting Hardware Included | For Use Outdoors | Lengths, ft. | Per Ft. | |

304 Stainless Steel | |||||||||||

| 1 | 1" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 1 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 1 | 1 1/2" | 3/16" | 1 3/16" | 4" | 2,368 lbs./sq. ft. @ 2 ft. | 0.057" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1 1/2" | 3/16" | 1 3/16" | 4" | 2,368 lbs./sq. ft. @ 2 ft. | 0.057" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1 1/2" | 3/16" | 1 3/16" | 4" | 2,368 lbs./sq. ft. @ 2 ft. | 0.057" @ 2 ft. | No | Yes | 0000000 | 000000 | |

Width | Length | Bearing Bar | Uniform Load | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max., ft. | Tolerance | Max., ft. | Tolerance | Ht. | Wd. | Center-to-Center Wd. | Center-to-Center Cross Bar Lg. | Rating @ Unsupported Lg. | Deflection @ Unsupported Lg. | Mounting Hardware Included | For Use Outdoors | Per Sq. Ft. | |

304 Stainless Steel | |||||||||||||

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 0000000 |

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 |

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1 1/2" | 3/16" | 1 3/16" | 4" | 2,368 lbs./sq. ft. @ 2 ft. | 0.057" @ 2 ft. | No | Yes | 0000000 | 000000 |

Bearing Bar | Uniform Load | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd., ft. | Ht. | Wd. | Center-to-Center Wd. | Center-to-Center Cross Bar Lg. | Rating @ Unsupported Lg. | Deflection @ Unsupported Lg. | Mounting Hardware Included | For Use Outdoors | Lengths, ft. | Per Ft. | |

304 Stainless Steel | |||||||||||

| 1 | 1" | 3/16" | 1 3/16" | 4" | 592 lbs./sq. ft. @ 2 ft. | 0.114" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 1 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 1 | 1 1/2" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1" | 3/16" | 1 3/16" | 4" | 592 lbs./sq. ft. @ 2 ft. | 0.114" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 2 | 1 1/2" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1" | 3/16" | 1 3/16" | 4" | 592 lbs./sq. ft. @ 2 ft. | 0.114" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 | |

| 3 | 1 1/2" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 | |

Width | Length | Bearing Bar | Uniform Load | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max., ft. | Tolerance | Max., ft. | Tolerance | Ht. | Wd. | Center-to-Center Wd. | Center-to-Center Cross Bar Lg. | Rating @ Unsupported Lg. | Deflection @ Unsupported Lg. | Mounting Hardware Included | For Use Outdoors | Per Sq. Ft. | |

304 Stainless Steel | |||||||||||||

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1" | 3/16" | 1 3/16" | 4" | 592 lbs./sq. ft. @ 2 ft. | 0.114" @ 2 ft. | No | Yes | 0000000 | 0000000 |

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1 1/4" | 3/16" | 1 3/16" | 4" | 1,053 lbs./sq. ft. @ 2 ft. | 0.086" @ 2 ft. | No | Yes | 0000000 | 000000 |

| 3 | -0.25" to 0.25" | 24 | -0.25" to 0.25" | 1 1/2" | 3/16" | 1 3/16" | 4" | 1,645 lbs./sq. ft. @ 2 ft. | 0.069" @ 2 ft. | No | Yes | 0000000 | 000000 |

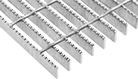

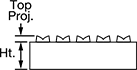

Plank Grating

Use plank grating for platforms, stair treads, ramps, and decks. Openings allow light to pass through and water to drain. Cut grating with a band saw, hack saw, circular saw, or shears. Use Fasteners for Plank Grating to secure.

Style A are serrated to provide maximum slip resistance.

Drainage Opening | Uniform Load | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Top Projection | Thick. | Gauge, ga. | Wd. | Lg. | Rating @ Unsupported Lg. | Deflection @ Unsupported Lg. | Mounting Hardware Included | For Use Outdoors | Per Ft. | |

2-, 3-, 4-, 5-, 6-, and 8-ft. Lengths | ||||||||||||

304 Stainless Steel | ||||||||||||

| 4 3/4" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | Not Rated | Not Rated | No | Yes | 0000000 | 000000 |

| 7" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | Not Rated | Not Rated | No | Yes | 0000000 | 00000 |

| 9 1/2" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | 750 lbs./sq. ft. @ 2 ft. | 0.06" @ 2 ft. | No | Yes | 0000000 | 00000 |

| 11 3/4" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | 606 lbs./sq. ft. @ 2 ft. | 0.05" @ 2 ft. | No | Yes | 0000000 | 00000 |

10- and 12-ft. Lengths | ||||||||||||

304 Stainless Steel | ||||||||||||

| 4 3/4" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | Not Rated | Not Rated | No | Yes | 0000000 | 00000 |

| 7" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | Not Rated | Not Rated | No | Yes | 0000000 | 00000 |

| 9 1/2" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | 750 lbs./sq. ft. @ 2 ft. | 0.06" @ 2 ft. | No | Yes | 0000000 | 00000 |

| 11 3/4" | 2" | 7/16" | 1/16" | 16 | 11/16" | 1 7/8" | 606 lbs./sq. ft. @ 2 ft. | 0.05" @ 2 ft. | No | Yes | 0000000 | 00000 |

| Fasteners for Style A Grating (Pkg. of 20) | 000000 | Pkg. | 000000 |

Heavy Duty Metal Antislip Tape

Metal abrasives embedded in a metal backing allow this tape to last far longer than other antislip tape. It is often used to cover larger areas than other antislip tape, such as walkways and ramps. Tape has an adhesive backing and can be walked on immediately after installation.

Fold-Up Steps

Flip these steps down when you need them and fold them up when you don’t. They can be bolted onto a stable surface, such as a wall. All steps have a diamond-plate or serrated tread for maximum slip resistance.

Style 1 have a cutout and rounded edges that you can grab with your hand if needed.

Stainless steel steps are corrosion resistant. 304 stainless steel steps have good chemical resistance. 316 stainless steel steps offer the highest corrosion resistance and the best protection against chemicals and salt water.

Note: Check local, state, and federal codes, including OSHA, for safe operating practices.

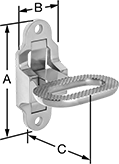

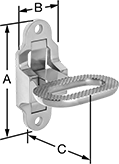

Overall | Step | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. (A) | Wd. (B) | Dp. (C) | Wd. | Dp. | Tread | Projection | Wt., lbs. | Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Each | |

304 Stainless Steel | ||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Plate | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||||

| 4 3/8" | 1 7/8" | 3 1/2" | 3 3/8" | 2" | Diamond Plate | 3 1/2" | 1 | Not Rated | No | 2 | 5/16" | 3 5/8" | 0000000 | 00000 |

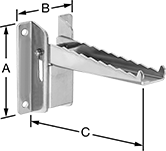

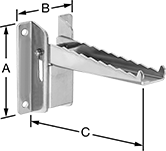

Overall | Step | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. (A) | Wd. (B) | Dp. (C) | Wd. | Dp. | Tread | Projection | Wt., lbs. | Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Each | |

304 Stainless Steel | |||||||||||||||

| 3 3/8" | 2 3/8" | 5 5/8" | 1" | 4 1/4" | Serrated | 5 5/8" | 1 | Not Rated | No | 4 | 3/16" | 2 5/8" | 1 3/4" | 0000000 | 000000 |

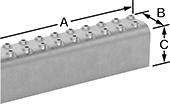

Ladder-Style Steps

Good for use as ladder rungs, cut these steps to size with a metal-cutting saw and weld them in place. For a clean weld, match the step material to the surface you are welding to. These steps must be welded at each end with welds capable of supporting the rated capacity. For those 5 ft. and longer, the maximum cut length is 24". Shorter lengths support higher capacities.

Serrated steps give you maximum slip resistance and allow liquids and debris to pass through. Perforated steps are less slip-resistant than serrated steps but offer a more comfortable hand grip.

Note: Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | |||||

|---|---|---|---|---|---|

| Wd. (A) | Dp. (B) | Ht. (C) | Capacity | Each | |

304 Stainless Steel | |||||

With Serrated Tread | |||||

| 17" | 1 1/8" | 1 1/4" | 540 lbs. | 0000000 | 000000 |

| 7 ft. | 1 1/8" | 1 1/4" | 250 lbs. for 18"-24" Cut Lengths, 540 lbs. Up to 18" Cut Lengths | 000000 | 000000 |

With Perforated Tread | |||||

| 5 ft. | 1 1/4" | 1 1/2" | 230 lbs. for 18"-24" Cut Lengths, 300 lbs. Up to 18" Cut Lengths | 00000000 | 00000 |

| 5 ft. | 2 1/4" | 1 1/2" | 380 lbs. for 18"-24" Cut Lengths, 510 lbs. Up to 18" Cut Lengths | 00000000 | 000000 |