Filter by

Jack Type

Mount Type

Weight Capacity

Height

Working Orientation

Application

Power Source

Material

Export Control Classification Number (ECCN)

Body Material

Base Material

Leg Shape

DFARS Specialty Metals

Mount Movement

Lift

Leveling Jacks

|  |  |  |  |

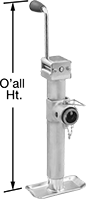

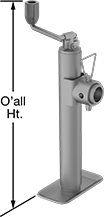

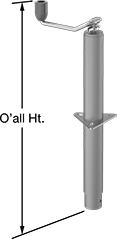

Side Handle Style A | Top Handle Style A | Side Handle Style B | Top Handle Style B | Top Handle Style D |

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Weight Capacity | Ht. | Max. Lift | Overall Ht. | Handle Lg. | Body Material | For Hole Dia. | Fasteners Included | No. of Holes | Hole Lg. | Hole Wd. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

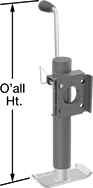

Weld On Side Mount with Rectangular Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 ton/2,000 lb. | 10 7/8" to 20 7/8" | 10" | 22 3/4" | 5 7/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 1/2 ton/5,000 lb. | 10 3/8" to 20 3/8" | 10" | 22 7/8" | 6 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 1/2 ton/5,000 lb. | 15 3/8" to 30 3/8" | 15" | 27 7/8" | 6 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Top Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 1/2 ton/5,000 lb. | 14 1/2" to 29 1/2" | 15" | 27 1/2" | 7 5/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld On Side Mount with Square Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 ton/2,000 lb. | 15" to 30 1/2" | 15 1/2" | 32 3/4" | 6 1/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Top Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 ton/2,000 lb. | 14 3/4" to 29 3/4" | 15" | 30" | 6" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

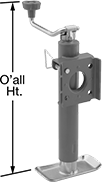

Weld On Side Mount with Tubular Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 ton/2,000 lb. | 10 7/8" to 20 7/8" | 10" | 23" | 5 7/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 ton/2,000 lb. | 15" to 30 1/2" | 15 1/2" | 32 3/4" | 6 1/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 1/2 ton/5,000 lb. | 10 1/2" to 20 1/2" | 10" | 23" | 6 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 1/2 ton/5,000 lb. | 15 1/2" to 30 1/2" | 15" | 28" | 6 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3 1/2 ton/7,000 lb. | 11" to 21" | 10" | 25 5/8" | 8 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 ton/10,000 lb. | 17" to 29 5/8" | 12 5/8" | 39 1/2" | 13 1/2" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Top Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 1/2 ton/5,000 lb. | 11 1/4" to 21 1/4" | 10" | 18" | 7 5/8" | Steel | — | — | — | — | — | Foot Plate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On/Weld On/Through Hole with Triangular Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Top Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 2 1/2 ton/5,000 lb. | 10 7/8" to 25 7/8" | 15" | 24 3/8" | 7 5/8" | Steel | 2 1/4" | No | 3 | 7/16" | 13/16" | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

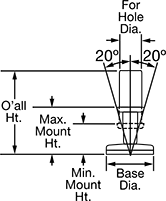

Sanitary Weld-On Swivel Leveling Mounts

With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Hole Dia., mm | Mounting Ht., mm | Swivel Range of Motion | Base Dia., mm | Food Industry Std. | Cap. per Mount, lb. | Overall Ht., mm | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 52 | 56 to 85 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 63 to 92 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

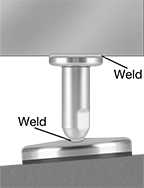

Weld-On Leveling Mount Inserts

For Square Legs

|

For Leg | Thread | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Outer Lg. | Outer Wd. | Cap. per Mount | Ht. | Size | Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | Not Rated | 1/4" | 3/8"-16 | UNC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | Not Rated | 1/4" | 1/2"-13 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | Not Rated | 1/4" | 5/8"-11 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | Not Rated | 1/4" | 3/4"-10 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | Not Rated | 1/4" | 3/8"-16 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | Not Rated | 1/4" | 1/2"-13 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | Not Rated | 1/4" | 5/8"-11 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | Not Rated | 1/4" | 3/4"-10 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | Not Rated | 1/4" | 3/8"-16 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | Not Rated | 1/4" | 1/2"-13 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | Not Rated | 1/4" | 5/8"-11 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | Not Rated | 1/4" | 3/4"-10 | UNC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||