Filter by

Cartridge Size

Opening ID

Material

Blade Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Body Material

Clarity

Environment

Body Clarity

Fitting Material

Mixer Nozzles for Two-Part Adhesive Cartridges

|  |  |  |

Tapered Tip | 3-Step Tip | 4-Step Tip | 5-Step Tip |

|  |  |  |

Blunt Tip | Luer-Lock Tip | Luer-Slip Tip | Combination Tip |

Bayonet Fitting Connection

Each | Package | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cartridge Size, fl. oz. | Mix Ratio | Opening ID | Lg. | No. of Mixing Elements | Mfr. | Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.42, 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 5.9" | 20 | — | Polypropylene | 00000000 | 00000 | 12 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 3.4" | 16 | — | Polypropylene | 00000000 | 0000 | 12 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 3.9" | 12 | — | Polypropylene | 00000000 | 0000 | 12 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 4.1" | 20 | — | Polypropylene | ——— | 0 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.21" | 3.3" | 16 | Loctite® | Polypropylene | 000000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1 | 0.059" to 0.188" | 6" | 21 | Loctite® | Polypropylene | 00000000 | 0000 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.05" to 0.07" | 5.9" | 20 | — | Polypropylene | 00000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blunt Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.19" | 3.3" | 12 | — | Polypropylene | 00000000 | 0000 | 12 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.19" | 5.3" | 20 | — | Polypropylene | 00000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Luer-Lock Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 4.1" | 20 | — | Polypropylene | 00000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1, 10:1 | 0.07" | 5.9" | 20 | — | Polypropylene | 00000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Luer-Slip Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1 | 0.063" | 6" | 20 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Combination Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1, 4:1 | 0.066" | 4.5" | 24 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bell-Mount Fitting Connection

Each | Package | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cartridge Size, fl. oz. | Mix Ratio | Opening ID | Lg. | No. of Mixing Elements | Mfr. | Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.11" to 0.13" | 6.3" | 24 | — | Polypropylene | 00000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.12" to 0.37" | 7.3" | 18 | — | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.12" to 0.37" | 9.2" | 24 | — | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.07" to 0.21" | 7.3" | 20 | 3M | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.118" to 0.35" | 8.4" | 18 | — | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.157" to 0.45" | 11.5" | 24 | — | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.66" | 5" | 20 | 3M | Polypropylene | 00000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Combination Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.52 | 1:1, 2:1, 4:1 | 0.066" | 5" | 24 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Snap-In Fitting Connection

Each | Package | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cartridge Size, fl. oz. | Mix Ratio | Opening ID | Lg. | No. of Mixing Elements | Mfr. | Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.52 | 1:1, 2:1 | 0.07" | 5.2" | 24 | Loctite® | Polypropylene | 0000000 | 00000 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.52 | 1:1, 2:1 | 0.07" | 7.6" | 24 | Loctite® | Polypropylene | 000000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.8 | 10:1 | 0.394" | 8.7" | 18 | SciGrip | Polypropylene | 000000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16.57 | 10:1 | 0.094" to 0.235" | 9.1" | 24 | Loctite® | Polyethylene | 0000000 | 0000 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Fitting Connection

Twist Lock Fitting Connection

Each | Package | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cartridge Size, fl. oz. | Mix Ratio | Opening ID | Lg. | No. of Mixing Elements | Mfr. | Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.01 | 1:1 | 0.246" | 3.5" | 12 | — | Polypropylene | 0000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.52 | 10:1 | 0.08" | 3.6" | 16 | 3M | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.64, 1.69 | 1:1, 2:1, 2:3 | 0.08" | 3.6" | 16 | 3M | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.039" | 3" | 16 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.07" | 3.6" | 16 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.13" | 4.8" | 16 | Loctite® | Polypropylene | 000000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 4:1, 10:1 | 0.07" | 4.8" | 24 | Loctite® | Polypropylene | 0000000 | 0000 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 4:1, 10:1 | 0.1" | 2.4" | 16 | Loctite® | Polypropylene | 000000000 | 0000 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | 100:85 | 0.1" | 2.4" | 16 | Loctite® | Polypropylene | 000000000 | 0000 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.64, 1.69 | 1:1, 2:1 | 0.04" to 0.193" | 5.8" | 20 | 3M | Polypropylene | 0000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.06" to 0.26" | 6.2" | 20 | Loctite® | Polypropylene | 00000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 1:1, 2:1 | 0.26" | 6.2" | 20 | — | Polypropylene | 00000000 | 0000 | 12 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | 10:1 | 0.06" to 0.26" | 6.2" | 20 | Loctite® | Polypropylene | 00000000 | 0000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

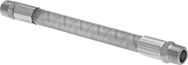

Plastic Inline Pipe Mixers

|

Pipe Size | Thread Type | Gender | Lg. | Blade Material | Body Material | Fitting Material | For Use With | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

12 Blades—Min. Reynolds Number 500 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 10" | Acetal | Polypropylene | Brass | Solvents, Water-Based Liquids | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 Blades—Reynolds Number 500 to 1,000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 8 1/2" | Acetal | Polypropylene | Brass | Solvents, Water-Based Liquids | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18 Blades—Reynolds Number 10 to 500 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 11 1/8" | Acetal | Nylon | Brass | Solvents, Water-Based Liquids | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

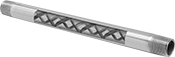

Stainless Steel Inline Pipe Mixers

|

Cutaway View |

Pipe Size | Thread Type | Gender | Lg. | Blade Material | Body Material | Fitting Material | For Use With | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

6 Blades—Min. Reynolds Number 1,000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 3" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 4" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 5" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 7" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | NPT | Male | 9" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 13" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | NPT | Male | 17" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 Blades—Reynolds Number 500 to 1,000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 6" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 8" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 10" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 13" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | NPT | Male | 17" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 26" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | NPT | Male | 33" | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | Oil, Wastewater | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Inline Pipe Mixers

|

Pipe Size | Thread Type | Gender | Lg. | Blade Material | Body Material | Fitting Material | For Use With | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

6 Blades—Min. Reynolds Number 1,000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 6 1/2" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 7" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 9" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | NPT | Male | 11" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | NPT | Male | 14" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 15" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | NPT | Male | 19" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 Blades—Reynolds Number 500 to 1,000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | NPT | Male | 11" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 12" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 15" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | NPT | Male | 18" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | NPT | Male | 25" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 28" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | NPT | Male | 35" | PVC | PVC | PVC | Chlorine, Water | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inline Tube Mixers

Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | ID | Lg. | Blade Material | Body Material | Max. Temp., ° F | For Use With | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

21 Blades | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.188" | 0.132" | 6" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.375" | 0.319" | 11" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.43" | 16 3/8" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32 Blades | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.375" | 0.319" | 17" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.43" | 24 3/4" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

34 Blades | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.194" | 11 1/2" | 316 Stainless Steel | 316 Stainless Steel | 300 | Oil, Solvents, Wastewater, Water-Based Liquids | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Inline Tube Mixers

|

Cutaway View |

Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | ID | Lg. | Blade Material | Body Material | Interior Smoothness, Ra | For Use With | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 Blades—Min. Reynolds Number 1,500 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.37" | 5 1/2" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.62" | 7" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.87" | 9" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.37" | 14" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1.87" | 18" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.37" | 22" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 2.87" | 27" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 3.83" | 36" | 316 Stainless Steel | 316 Stainless Steel | 20 | Beverage, Dairy, Food | ASME BPE | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

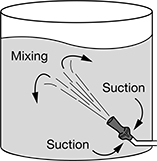

Tank Mixing Nozzles

Orifice Dia. | Pipe Size | Thread Type | Gender | Inlet Flow Rate @ Pressure | Tank Circulation Rate @ Pressure | Dia. | Lg. | Max. Pressure @ Temp. | Max. Temp., ° F | Material | Color | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06" | 1/4 | NPT | Male | 0.7 gpm @ 50 psi | 4.4 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Orange | 0000000 | 000000 | |

| 0.08" | 1/4 | NPT | Male | 1.2 gpm @ 50 psi | 6 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Green | 0000000 | 00000 | |

| 0.1" | 1/4 | NPT | Male | 2 gpm @ 50 psi | 7.8 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Blue | 0000000 | 00000 | |

| 0.12" | 1/4 | NPT | Male | 2.9 gpm @ 50 psi | 10.7 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | White | 0000000 | 00000 | |

| 3/16" | 1/4 | NPT | Male | 7.8 gpm @ 50 psi | 36.8 gpm @ 50 psi | 1 1/4" | 3" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 5/16" | 3/8 | NPT | Male | 20 gpm @ 50 psi | 100 gpm @ 50 psi | 1 11/16" | 4 1/16" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 3/8" | 3/4 | NPT | Male | 30 gpm @ 50 psi | 150 gpm @ 50 psi | 3" | 6 3/8" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 9/16" | 1 1/2 | NPT | Male | 75 gpm @ 50 psi | 375 gpm @ 50 psi | 4 1/2" | 10" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 000000 |