Filter by

Material

Outside Height

Outside Width

Wall Thickness

Beam Trade Size

Inside Width

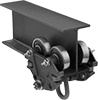

Specifications Met

Weight Capacity

Height

Yield Strength

Inside Height

Appearance

Beam Width

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Raw Materials

Material Handling

Building and Machinery Hardware