Filter by

Step Tread

Weight Capacity

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Ladder-Style Steps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Weight Capacity | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

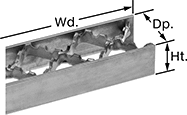

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 7/8" | 540 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

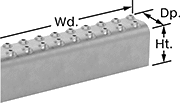

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 17" | 2" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7 ft. | 2" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 220 lb. for 18" to 24" Cut Lengths, 290 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 310 lb. for 18" to 24" Cut Lengths, 410 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 540 lb. for 18" to 24" Cut Lengths, 720 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 230 lb. for 18" to 24" Cut Lengths, 300 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 380 lb. for 18" to 24" Cut Lengths, 510 lb. Up to 18" Cut Lengths | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

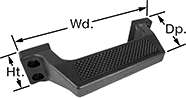

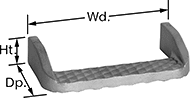

Step Handles

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material | Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Color | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plastic | 1 5/8" | 6 3/8" | 2 1/2" | 3 1/4" | 1 1/8" | Diamond Tread | 2 1/2" | 0.22 | Black | No | 4 | 1/4" | 3/4" | 5 1/2" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 1 3/4" | 7 3/4" | 4 1/8" | 6 3/4" | 1 5/8" | Diamond Tread | 4 1/8" | 3.2 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum | 1 5/8" | 7 3/4" | 4 1/8" | 7" | 1 5/8" | Diamond Tread | 4 1/8" | 1.12 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||