Filter by

Strut Channel Type

Strut Channel Framing Component

Channel Height

Length

Construction

Thickness

ID

Height

Width

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Framing Type

Strut Channel Framing and Fittings

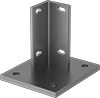

Brackets

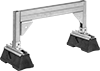

Feet

Nuts

Suspension Mounts

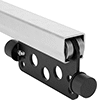

Curtain Slides

Spool Rack Mounts

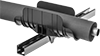

Channel

Washers

Shelf Brackets

Covers

Cable Tie Mounts

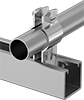

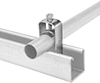

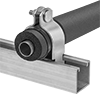

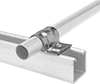

Rod Stabilizers

Beam Mounts

Routing Clamps

Stair Tread Mounts

Conduit Connection Plates

Hangers

Threaded Rod Brackets

Routing Saddles

Channel Adapters

Other Products