Digital Coating-Thickness Gauges with Certificate of Calibration

These gauges come with a calibration certificate traceable to NIST that states they've passed a test for accuracy. Use them to measure coatings such as paint, galvanizing, plating, and enamel. They display readings in mils and microns; for readings in mils, one mil equals 0.001". All have a wear-resistant ruby probe.

For Coating Thick. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Coating Type | Mil | Microns | Accuracy | Wd. | Ht. | Dp. | Reading Storage Cap. | Batteries Included | Includes | Features | Specifications Met | Each | |

For Use On Aluminum, Copper, Stainless Steel, Steel | |||||||||||||

| Nonmagnetic, Nonconductive | 0-60 | 0-1,500 | ±1% | 2 3/8" | 5 3/8" | 1 1/8" | 1,000 | Yes | __ | Built-In Probe, High/Low Limits | ASTM B499, ASTM D1186, ASTM D1400, ISO 2808 | 0000000 | 000000000 |

| Nonmagnetic, Nonconductive | 0-60 | 0-1,500 | ±1% | 2 3/8" | 5 3/8" | 1 1/8" | 1,000 | Yes | Detachable Probe with 3 ft. Cable | High/Low Limits | ASTM B499, ASTM D1186, ASTM D1400, ISO 2808 | 0000000 | 00000000 |

For Use On Steel | |||||||||||||

| Nonmagnetic | 0-60 | 0-1,500 | ±1% | 2 3/8" | 5 3/8" | 1 1/8" | 1,000 | Yes | __ | Built-In Probe, High/Low Limits | ASTM B499, ASTM D1186, ASTM D1400, ISO 2808 | 0000000 | 000000 |

Digital Coating-Thickness Gauges

Measure coatings such as paint, galvanizing, plating, and enamel. These gauges display readings in mils and microns; for readings in mils, one mil equals 0.001". They have a wear-resistant ruby probe.

Economy Coating-Thickness Gauges for Hard-to-Reach Areas

This pen-shaped gauge is good for use on hard-to-reach surfaces. Use it to measure nonmagnetic coatings such as paint, galvanizing, plating, and enamel on steel. This gauge displays readings in mils; one mil equals 0.001".

| For Coating Type | For Coating Thick., mil | Accuracy | Lg. | Dia. | Each | |

For Use On Steel | ||||||

|---|---|---|---|---|---|---|

| Nonmagnetic | 1-15 | ±0.2 mils | 5 1/4" | 1/2" | 00000000 | 000000 |

Coating-Thickness Gauges for Hard-to-Reach Areas

This pen-shaped gauge is good for use on hard-to-reach surfaces. Use it to measure nonmagnetic coatings such as paint, galvanizing, plating, and enamel on steel. This gauge displays readings in mils and microns. For readings in mils, one mil equals 0.001". It comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy.

For Coating Thick. | |||||||

|---|---|---|---|---|---|---|---|

| For Coating Type | Mil | Microns | Accuracy | Lg. | Dia. | Each | |

For Use On Steel | |||||||

| Nonmagnetic | 1/4-20 | 5-500 | ±10% | 5 1/2" | 1/4" | 0000000 | 0000000 |

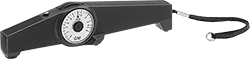

Coating-Thickness Gauges

Use these gauges to measure nonmagnetic coatings such as paint, galvanizing, plating, and enamel on steel. All come with a calibration certificate traceable to NIST that states they've passed a test for accuracy.

Hold the probe on your material for a quick reading. These gauges display readings in mils; one mil equals 0.001". They have a wear-resistant carbide probe and a go/no-go button for rapid measurement. A V-groove in the base provides stability on curved surfaces.

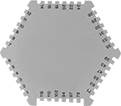

Wet-Coating-Thickness Gauges

Measure the thickness of wet coatings such as paint. These gauges display readings in mils on one side and microns on the other side. For readings in mils, one mil equals 0.001".

For Coating Thick. | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Coating Type | Mil | Microns | Wd. | Lg. | Material | Specifications Met | Each | |

For Use On Aluminum, Copper, Plastic, Stainless Steel, Steel | ||||||||

| Nonconductive, Nonmagnetic | 1-118 | 25-3,000 | 2 5/8" | 3" | Aluminum | ASTM D4414, ISO 2808 | 000000 | 000000 |

Coating-Thickness Gauge Inspection Kits

With three included probes, the gauge in these kits goes beyond a typical check for coating thickness. It also measures surface profile and environmental conditions, such as temperature. Kits include everything you need for thorough tests whether you’re inspecting a surface that’s painted, powdered, or plated. Just swap out probes to measure what you need. Use the plate and shims to practice measurements and ensure the probe is working properly. The glass plate and metal shims work with the surface profile probe. The plastic shims work with the coating thickness probe. Easy to use, the gauge’s touch screen guides you through measurements step-by-step.

Switch between scan modes for full control over how you measure, from single-point tests to continuous readings. You can even find stats and create presets for repeated measurements. For long-term tracking, the gauge stores up to 250,000 results from multiple probes in up to 1,000 batches. See trends in real time with live graphing. To help you comply with ISO, ASTM, SSPC-PA, and IMO coating standards, set criteria for go/no-go tests.

Thanks to a compatible app, you can add notes and images to readings or make reports on the go. For exporting into programs such as Excel or making multimedia reports in templates, use the included software.

Choose kits based on coating and surface types. Kits with probes for both nonconductive and nonmagnetic coatings include a thickness probe that automatically identifies the coating and surface material. Kits with probes for 0-250 mil coating thickness are ideal for testing epoxies, flame-retardant finishes, and other thick coatings.

A built-in probe lets you use the gauge one-handed—no extended probe to maneuver. A detachable probe means you can measure underwater and up to 3 ft. away. The waterproof probes are at the end of sealed cable, so you can reach surfaces without submerging the gauge.

For Coating Thick. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Coating Type | Mil | Microns | Accuracy | Reading Storage Cap. | Batteries Included | Data Connection Type | Includes | Features | Specifications Met | Each | |

For Use On Aluminum, Copper, Stainless Steel, Steel | |||||||||||

Built-In Probe | |||||||||||

| Nonconductive, Nonmagnetic | 0-60 | 0-1,500 | ±1% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 000000000 |

Detachable Probe with 3 ft. Cable | |||||||||||

| Nonconductive, Nonmagnetic | 0-60 | 0-1,500 | ±1% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 00000000 |

For Use On Steel | |||||||||||

Built-In Probe | |||||||||||

| Nonmagnetic | 0-60 | 0-1,500 | ±1% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 00000000 |

| Nonmagnetic | 0-250 | 0-6,000 | ±3% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 00000000 |

Detachable Probe with 3 ft. Cable | |||||||||||

| Nonmagnetic | 0-60 | 0-1,500 | ±1% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 00000000 |

| Nonmagnetic | 0-250 | 0-6,000 | ±3% | 250,000 | Yes | Bluetooth, USB | Coating Thickness Probe Environmental Probe Surface Profile Probe Gauge Body Zero-Setting Glass Plate Plastic and Metal Shims Lens Shield Rubber Holster Wrist Strap USB Cable Case | Alarm Batch Mode Limited Count Coverage Scan Mode Live Graphing Normal Scan Mode Statistics Scan Mode Zero-Position Memory (ABS) Zero-Set Button | ASTM D4417, ISO 19840 | 0000000 | 00000000 |

Ultrasonic Painted-Surface Thickness Gauges

Measure the thickness of painted metal without removing the coating. The ultrasonic probe provides highly accurate readings. This gauge comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy. It also includes a USB cord for connecting to your PC. Use the included ultrasonic gel for maximum surface contact.

Use calibration blocks to calibrate your thickness gauge. All blocks have a serial number and come with a calibration certificate traceable to NIST.